Exploring the Mysteries of Space

Space is enveloped in countess mysteries. The space probe "Hayabusa", developed to explore these mysteries, incorporates technology from the SHI Group. This is the "horn," a mechanism that extends from the probe like a bellows once it reaches an asteroid. The horn captures rock fragments rising from the asteroid surface and immediately seals them in a collection capsule to ensure that they do not become mixed with other material. In this way, "Hayabusa" was able to successfully bring back to Earth samples that may hold the key to the mysteries of the creation of the universe. Below we introduce the amazing technology at the heart of the sample collection mechanism of "Hayabusa".

Like an Elaborate Mechanical Doll

- *Credit: Yoshida Research Lab, Tohoku University

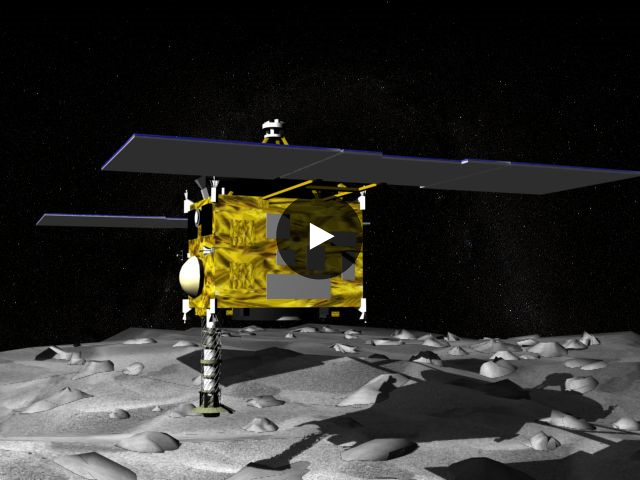

The return to Earth of the "Hayabusa" asteroid probe in June 2010 caused great excitement in Japan and throughout the world. The capsule recovered from the probe was found to contain rock particles from the asteroid Itokawa. This was the first time in the history of human space development that a probe landed on the surface of a heavenly body outside Earth's gravitational field and returned with samples. A sample collection mechanism developed by the SHI Group made an important contribution to this major discovery.

A long cylindrical object called a "horn" is mounted on the bottom of the probe. This is the key element of the sample collection mechanism. Once "Hayabusa" makes contact with the asteroid, it fires a projectile from a gun-like device called a projector into the asteroid surface. The fragments kicked up by the impact then pass through the horn into the interior of "Hayabusa". Inside the horn are a container for capturing samples and a mechanism for conveying it to the collection capsule. The samples enter the capture container inside the probe. Then the capture container is conveyed into the collection capsule, which seals it off.

The collection mechanism consists of eight moving parts but uses no motors at all. Most of the necessary movements are implemented by springs. This mechanism can be thought of as similar to the elaborate karakuri ningyo mechanical dolls manufactured in Japan in the Edo period (1603-1868).

A Structure that Expands and Contracts Freely, Inspired by the Bellows of a Paper Lantern

Itokawa is a heavenly body that has never been visited by any human. We really had no idea what sort of configuration the surface would have in the location where the probe touched down. SHI engineers studied a variety of horn materials, angles, and other factors in order to cope with all imaginable eventualities. One key idea was to use a bellows-like structure for part of the horn. This mechanism allowed the horn to be retracted when the probe was launched and then to be extended once its was aloft. The traditional Japanese paper lantern was the inspiration for this idea. One of the designers purchased a souvenir paper lantern at the train station in Niihama, Ehime Prefecture, and studied its structure.

A special fiber was used to make the portion of the horn corresponding to the skin of the bellows. This was done to prevent rock fragments flying back from the surface of the asteroid from piercing the horn and damaging the probe. Springs woven in with the fibers formed the portion of the horn corresponding to the bamboo "ribs" of a paper lantern.

The components mounted on the probe had to provide a high tolerance for mechanical shocks and vibrations while also being lightweight. Materials such as aluminum or magnesium alloys were used for the metal parts in order to shave off every extra gram of weight. A portion of the horn had to be colored black due to considerations related to observation, so a black film was applied by hand to the bellows.

The sophisticated design of the mechanism incorporated some surprising elements of analog technology. A full seven years were needed from the initial study of specifications to final completion of the design, a process that included many modifications to the specifications, repeated tests under simulated vacuum conditions, and finally general tests of the horn mounted on the probe body.

Design Expertise Inherited by Hayabusa 2

The Quantum Equipment Div., which was responsible for the design and development of the sample collection mechanism, had previously developed a number of components for scientific satellites such as "Akari" and "Suzaku". These include observation devices designed to operate at very low temperatures, mirrors used in sensors for analyzing sea surface temperatures, and devices for use in gas synthesis experiments in space. Their ample experience and expertise in designing equipment for spacecraft was one of the reasons for the success of the development effort.

We must also not overlook the passion of the design and manufacturing team, who maintained their high level of motivation over a period of eight years.

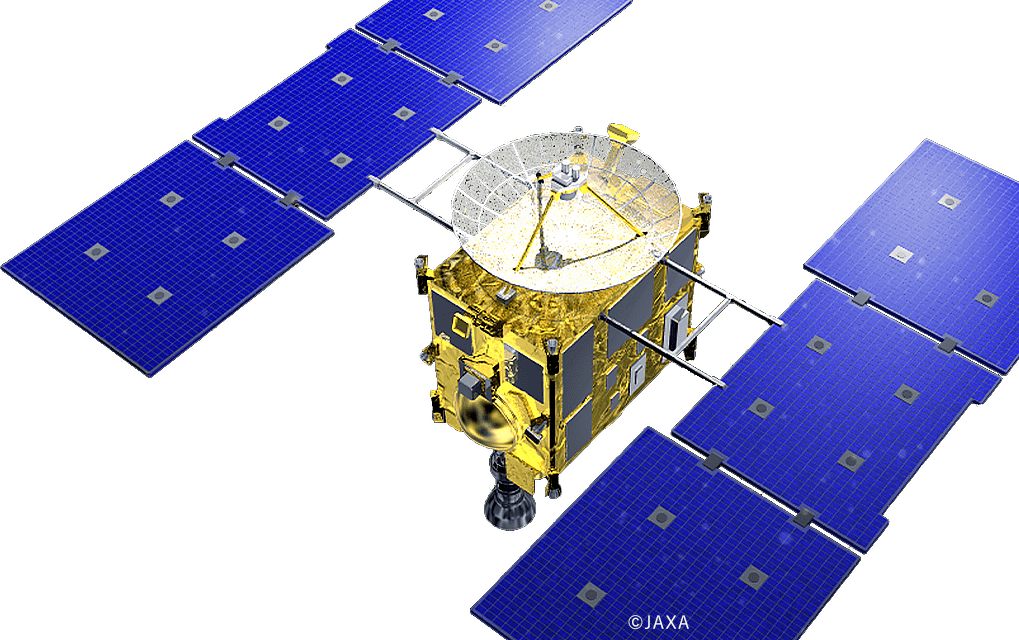

The fruits of the "Hayabusa" project will be further extended by "Hayabusa 2", which is scheduled for launch in 2014. "Hayabusa 2" will explore another asteroid where there is considered to be a high likelihood of the existence of organic matter. The basic structure of the probe will be the same as that of its predecessor, but partial modifications to the collection mechanism are being considered in hopes of gathering a larger volume of samples.

This endeavor will make use of the accumulated expertise of the SHI Group's business divisions in building equipment that can function under conditions of strong vibrations, high vacuum, and extreme temperatures. In addition to technology used in previous spacecraft, it will incorporate insights from other fields, such as medical equipment, as well.

- *All contents are as of the time of the interview.

SHI Pride

- Vol.1 A Clear View of the Distant Heavens

- Vol.2 Cures without Surgery: Advanced Cancer Treatment

- Vol.3 Exploring the Mysteries of Space

- Vol.4 Dramatically Changing Quayside Cargo Handling

- Vol.5 Cyclo Drives Continue to Evolve

- Vol.6 The Steam Turbine - Protecting the Environment and Advancing Society

- Vol.7 Persistent Determination to Reduce Defects, Losses and Faults to Zero

- Vol.8 Treating Cancer through the Use of Neutrons - A Compact Accelerator Opens the Door to Widespread Use -

- Vol.9 Automated storage system with unrestricted movement, for transforming the future of the logistics industry

- Vol.10 Anaerobic Wastewater Treatment and Biogas Power Generation System using Ume Seasoning Effluent bringing Recycling-Friendly Society

- #01 Technology that has the potential to dramatically change automobile frame manufacturing STAF created by maintaining a comprehensive customer perspective

- #02 The ECY Series:A smaller Gear reducer after over 10 years of development

- #03 Cancer Therapy System "Boron Neutron Capture Therapy (BNCT system)"

- #04 Supporting Development with Innovative Simulation Technology: RMD and MBM

- #05 Behind the Development of the World's Highest Output Accelerator for Proton Beam Cancer Therapy - Succeeding "When It Can't Be Done."

- #06 AI-backed support system for next generation biomass power plant operations ~ Transforming the shop floor with IZANA ~