Occupational Health and Safety

Basic Views

As we, the Sumitomo Heavy Industries Group, uphold the "SHI Group's Basic Philosophy of Safety and Health" as our policy, we are committed to ensuring the safety and health of all stakeholders, including our employees and support staff both within and outside our facilities.

Based on this policy, we formulated the Basic Safety Reform Plan in fiscal 2010 and have since strengthened initiatives aimed at preventing occupational accidents and promoting employee well-being.

Beginning in fiscal 2024, we have been advancing these efforts under the 5th Action Plan.

The SHI Group will work in cooperation with labor and management to ensure that the "safety first" policy is upheld by all employees to create pleasant workplaces where they can work in healthy, safe, and secure environments, based on a spirit of respect for human beings.

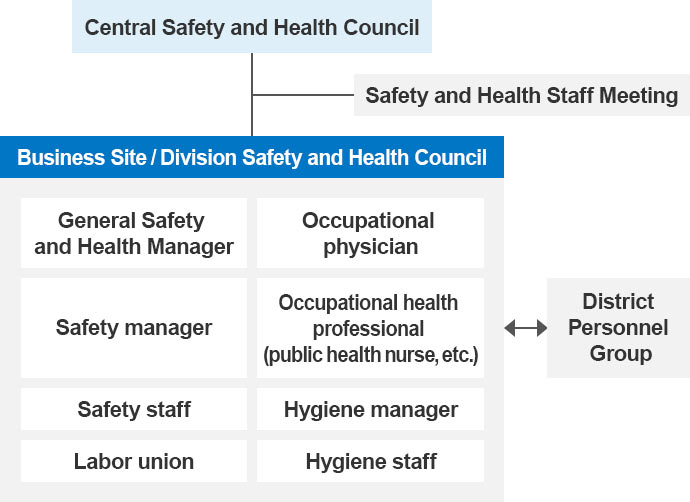

Safety and Health Promotion System

We have established the Central Safety and Health Council, chaired by the executive officer in charge of human resources, as a consultation body between the company and labor unions regarding safety and health.

This council discusses safety and health management structures and fundamental measures.

These measures are then implemented and followed up by the safety and health committees at each business site and divisions.

In addition, the Safety and Health Personnel Meeting formulates and implements basic policies and initiatives for the prevention of occupational accidents, and coordinates and standardizes key matters related to safety and health.

Activities

Expansion of ISO 45001 External Certification

To ensure the reliable operation of our occupational health and safety management systems, we have been promoting the acquisition of ISO 45001 certification from external certification bodies at each of our sites, and 83.3% of our major domestic sites have already acquired the certification. (as of the end of FY2024)

Equipment/Machinery Safety

In addition to training workers on work procedures, we aim to create a work environment that is free from occupational accidents by proactively allocating our budget based on risk assessments to ensure that all our equipment and machines are made safer and will not injure workers even if they make mistakes.

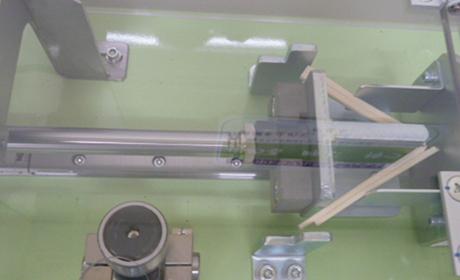

Cutting Machine

- Modified the existing motor cover to prevent finger entrapment

- Changed to an interlocking guard with a sensor

- Changed the removal of processed workpieces to be movable

Lathe-turning Machine

- The machine will stop automatically if the guard is removed during machining.

- An alarm will be activated if the safety sensor is disabled.

Safety Education

Occupational accidents will continue to happen unless each individual is able to predict hazards and avoid risks.

To improve the hazard-prediction capability of workers, we have introduced an education curriculum using hazard training and virtual reality in safety and health education.

From fiscal 2020, we are providing training for workers to increase their susceptibility to the risk of high-pressure gas and help them understand the importance of work procedures by introducing a device that demonstrates how hazardous it can be if their finger gets entrapped in an air cylinder.

Occupational Accidents

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Occupational Accident Frequency Rate (employees) | 0.0 | 0.3 | 0.4 | 0.7 | 0.9 |

| Occupational Accident Frequency Rate (employees and contract workers) | 0.2 | 0.6 | 0.5 | 0.7 | 0.8 |

- ・Accident Frequency Rate: Frequency of occupational accidents (number of fatalities and injuries resulting from occupational accidents per 1 million actual working hours)