Fluidized Bed Gasifiers

Economically & Efficiently Gasifying Biomass & Waste

Gasification is a process that turns solid fuels into gases - called syngas - which can be used for combustion or production of chemicals and synthetic fuels. The main components in the syngas are hydrogen and carbon monoxide, the basic "building blocks" of many valuable chemicals and fuels, such as methanol, diesel and jet fuel.

Gasification technology can unlock the value of waste streams by turning these into energy or feedstock for biorefineries, replacing fossil fuels, reducing CO2 emission and promoting circularity.

Air Gasification

Economically & Efficiently Gasifying Biomass & Waste

Gasification is a process that can find new value in traditional fuels such as biomass, municipal and industrial waste by converting these materials into combustible gases. The resulting gas, called syngas or product gas, can replace fossil fuels in multiple applications.

The air gasification process uses heat to break down low-quality solids or liquid fuels into their basic gaseous chemical components. The result is a gas stream rich in hydrogen and carbon monoxide, with calorific values up to 8 MJ/Nm3. This gas can be used in multiple applications, such as replacing fossil fuels in heat & power generation, lime and cement kilns and gas turbines.

Click here for detailed information about Air Gasification

Features

- 1The most fuel-flexible gasification technology in the market

Unlike other gasification technologies, our fluidized bed (FB) gasifiers can utilize a wide range of fuels, including waste streams such as refuse-derived fuels (RDF/REF), demolition wood, forest and agriculture residues, sludge, and other non-recyclable wastes.

- 2Superior fluidized bed technology for high efficiency

While other technologies use high temperatures and short residence times, our gasifiers take advantage of vigorous mixing and long particle residence times to efficiently gasify even the lower quality fuels. Another benefit of low-temperature fluid bed gasification technology is that the residual ash never melts, allowing the use of feedstocks considered too corrosive for other gasifiers.

- 3Replacing fossil fuels on existing processes

The air gasification system can be retrofitted to existing fossil-fuel plants, allowing local biomass and waste utilization. For instance, fluidized bed gasifiers can be installed next to pulverized coal units to take advantage of local wastes while reducing carbon emissions. Another application in the power generation sector is the Integrated Gasification Combined Cycle (IGCC). The technology can also be applied to replace fossil fuels in lime and cement kilns, reducing the carbon footprint of these processes.

- 4Gasification technology for recycling applications

Air gasification can be used to recover materials and energy from waste streams. For instance, carton board is widely consumed globally for liquid packaging. The wood fibre is recovered during the recycling process, but the remaining mixture of plastics and aluminium cannot be separated. our gasification technology allows the recovery of aluminium while generating heat and power from the non-recyclable plastic stream.

Oxy-Steam Gasification

From biomass and waste to synthetic fuels and chemicals

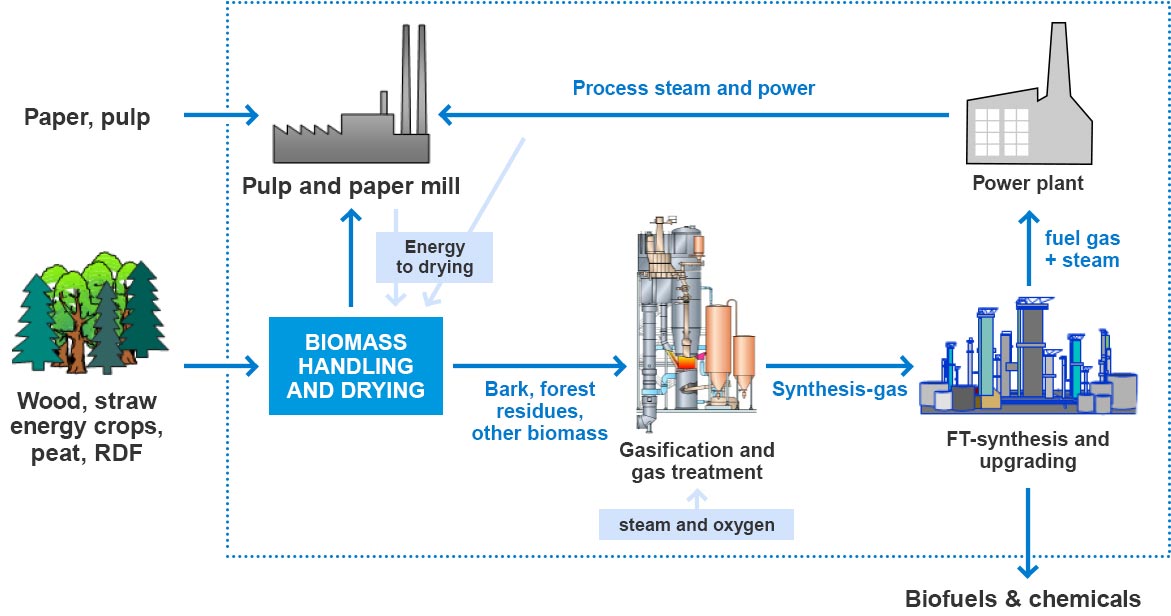

Oxy-steam Gasification is a process that converts traditional fuels such as biomass, municipal and industrial waste into valuable syngas. This technology uses a mixture of oxygen and steam, instead of air, as the gasifying agent. By replacing air with a mixture of oxygen and steam, the resulting gas is free from nitrogen, making it suitable for other applications than combustion.

In this case, the syngas' main components are hydrogen and carbon monoxide, the basic "building blocks" of many valuable chemicals and fuels, such as methanol, diesel and jet fuel. Thus, the oxy-steam gasification technology can unlock the value of waste streams by turning these into energy or feedstock for biorefineries, replacing transport fuels, reducing CO2 emissions and promoting circularity.

Click here for detailed information about Oxy-Steam Gasification

Features

- 1The most fuel-flexible gasification technology in the market

Unlike other gasification technologies, our fluidized bed (FB) gasifiers can utilize a wide range of fuels, including waste streams such as refuse-derived fuels (RDF/REF), demolition wood, forest residues, sludge, and other non-recyclable waste.

- 2Superior fluidized bed technology for high efficiency

While other technologies use high temperatures and short residence times, our gasifiers take advantage of vigorous mixing and long particle residence times to efficiently gasify even the lower quality fuels. Another benefit of low-temperature fluid bed gasification technology is that the residual ash never melts, allowing the use of feedstocks considered too corrosive for other gasifiers.

- 3Production of carbon-neutral chemicals and fuels

Since 2010, we have demonstrated the oxy-steam gasification, combined with and syngas cleaning system, for wood-based biomass type of feedstocks on a 12 MWth scale. The system produces ultra-clean syngas that can be used in the production of renewable diesel from biomass. The oxy-steam gasification technology can also be applied to convert waste to fuels and chemicals.