Flue Gas Denitrification Systems, Selective Catalytic Reduction and Selective non-Catalytic Reduction

Meeting stringent environmental limits - today and tomorrow

Nitrogen oxides, such as NO and NO2, are formed in most combustion processes. If left untreated, these pollutants, generally called NOx, can cause severe environmental consequences such as smog, acid rain and impacts on the ozone layer.

NOx emissions are prevented by converting these pollutants into N2 and H2O, common components in the atmosphere. The conversion can be done via:

- Selective Non-Catalytic Reduction (SNCR) process is based on the high-temperature reaction of gaseous ammonia or urea with nitrogen oxides without using a catalyst.

- Selective Catalytic Reduction (SCR) process uses the reaction of nitrogen oxides with ammonia in the presence of a catalyst at lower temperatures.

Both SNCR and SCR are based on the injection of ammonia or urea into the flue gas stream.

Features

- 1Optimized system design according to the site conditions

Parameters such as dustiness, sulfur content, flue gas temperature, and the space available for installation determine the best denitrification method. Our long experience in combustion processes and boiler design results in optimized denitrification systems regarding investment and operating costs for both new builds and retrofits.

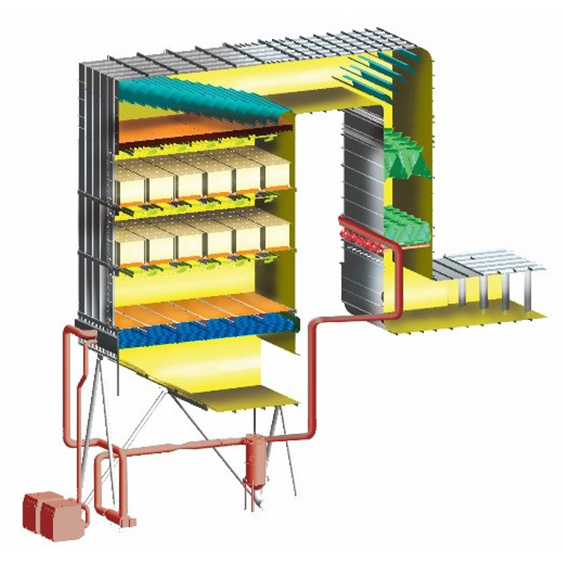

- 2High performance in any conditions

We deliver DeNOx systems in both "High Dust" (i.e. before flue gas treatment) and "Tail End" (i.e. after flue gas treatment) environments. With time, as the operating conditions in the plant change, SCR and SCNR systems can be expanded or optimized, allowing for further significant reductions in NOx emissions.

- 3Choice of the best catalyst according to the customer's requirements

Selecting the correct type of catalyst according to the site condition results in high-performance and lower operating costs. The type of catalyst is influenced by the fuel and flue gas composition, such as ash content. The oxidizing properties of catalysts for SCR also influence the oxidation degree of mercury from Hg0 to Hg2+, thus significantly contributing to mercury removal efficiency in the downstream flue gas equipment.

- 4Reduce costs by combining SNCR and SCR systems

It is possible to combine both methods into one system to decrease the costs while reaching emissions limits. In this case, the SNCR system performs an initial reduction of NOx. Emissions are further reduced by the remaining unreacted ammonia on the SCR catalytic layer after the non-catalytic process, thus reducing the consumption. This makes it possible to keep emissions at the required level. In the event of stricter emissions limits, the reduction rate can be increased by optimizing reagent injection and catalytic modules.

For detailed information about the products please contact

Phone

Sales Department, Energy & Environment Group

Web