Steam Turbines

Reliable advanced technology backed by experience, in response to today's needs. Superior performance that has gained a high level of credibility in the distributed type power generation market.

Small to medium size steam turbines from the SHI Group have a superior performance that has gained high credibility and is used as steam turbines in gas turbine combined cycles, as well as electric power generating facilities that use biomass or waste materials. Past performances for condenser type (multi-stage C type, and multi-stage axial exhaust type) steam turbines total about 6,500 units in about 80 countries around the world.

Click here for detailed information about Steam Turbines

Features

- 1Condenser type (multi-stage axial exhaust type)

The axial exhaust type is an evolution of the condenser type steam turbine. Conventional condenser steam turbines generally expel the exhaust gas in an upward or downward direction, which is at a right angle to the axis. Changing this so that the exhaust gas flows in the direction of the axis resulted in a reduction in exhaust gas losses, and a significant improvement in energy efficiency became possible. In terms of layout, conventional types required a large space in the downward or upward, but the axial exhaust type turbines from the SHI Group direct the exhaust gas in the direction of the axis. Since a condenser is connected directly, the layout is simple and construction costs are dramatically reduced, while significantly contributing to a reduction in both time and cost in maintenance and inspections.

Advantages of axial exhaust type turbines

- Increased mechanical efficiency

By expelling gas in the direction of the axis, exhaust losses are reduced in comparison to upward (or downward) exhausting types and the most efficient performance is possible.

- Reduced cost

Since everything, including the condenser, can be placed on a flat surface, construction costs for the foundation and the building can be reduced significantly.

- Shortening of lead time

A reduction in the concrete for the foundation and the volume of the building makes it possible to reduce site construction costs and the site construction lead time.

- Increased mechanical efficiency

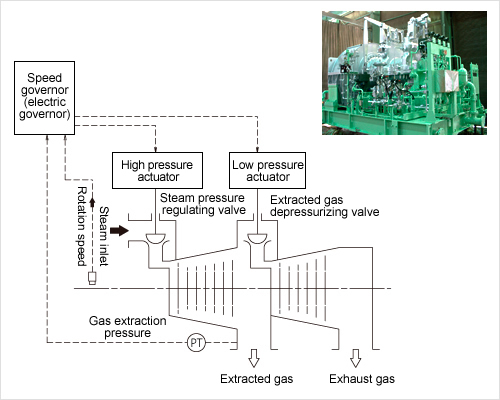

- 2Internal extraction pressure control type

In the case of steam extracted at an intermediate stage of the turbine and supplied to the manufacturing plant, control of the internal extraction pressure makes it possible to supply gas in a stable manner, from low to rated load on the turbine. The internal extraction pressure control is a method used to maintain the gas extraction pressure at a certain level by controlling the pressure on the upstream side, using a pressure control valve, which is installed inside the casing of the turbine. Since an internal control valve can be installed in up to two stages (intermediate and low pressure steam), it is possible to supply gas extracted from a single turbine unit to two locations in the manufacturing plant.

First stage internal extraction type turbine

Product lines

For detailed information about the products please contact

Web

Shin Nippon Machinery Co., Ltd.