Conservation of Water Resources

Basic Approach

The Sumitomo Heavy Industries Group recognizes the importance of ensuring that everyone has access to safe and sanitary water, and of protecting and restoring water-related ecosystems. Although we do not require large volumes or high levels of water in our current business activities, we fully understand that we are dependent on water, and are affected by or have an impact on the quantity and quality of water we consume, as we use and discharge municipal water, industrial water, and groundwater.

At our manufacturing sites both in Japan and overseas, we measure the amount of water we take in and discharge, and compile the data for the entire Group. For business locations where there are large fluctuations, we investigate the causes and take measures as necessary. In addition, for water quality management, we have set voluntary management standards that are stricter than the standards set by laws and ordinances, and we continuously monitor the quality of our water by conducting our own measurements and regular inspections by external water quality testing agencies.

We will continue to implement ongoing management and promote activities to reduce the environmental impact, such as reducing the amount of water we withdraw and the use of hazardous substances that may be contained in wastewater.

Additionally, as part of our collaboration with external initiatives to reduce water usage, we have been responding to CDP Water since fiscal 2018.

Governance

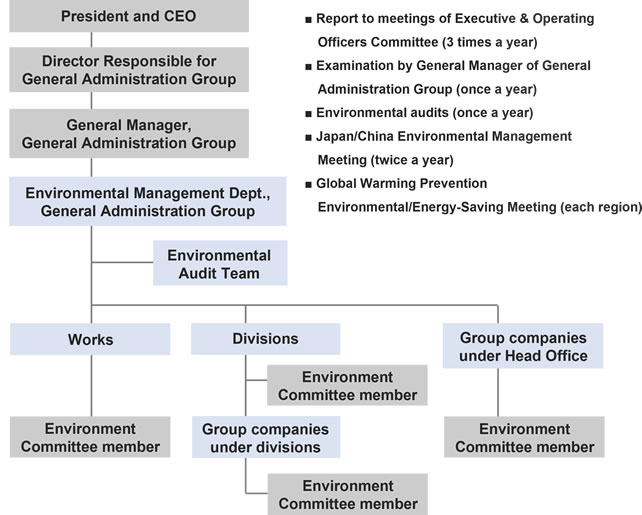

Environmental activity management for the entire Group is carried out by the General Affairs Division Chief and the Environmental Management Department under the Director in Charge of General Affairs, who is appointed by the President. As the person with ultimate responsibility, the President approves and determines the environmental policy of the Sumitomo Heavy Industries Group.

The Environmental Management Department conducts environmental audits of each manufacturing base, including affiliated companies, to check the local situation, and shares activity results and issues at the Environmental Management Meeting. In addition, we inform employees of our group's environmental policy, environmental goals, and activities through environmental education.

Activities

- Environmental audit (once a year)

- We conduct audits of our manufacturing bases in Japan, China, and Southeast Asia to examine their overall environmental management from the perspectives of preventing environmental accidents, complying with laws and regulations, and preventing global warming.

The audit results are evaluated on a five-point scale for each department based on our own unique evaluation criteria, which are reported at the Executive Officers Meeting to help improve the department's performance.

- Diagnosis by General Affairs Division Chief (when necessary)

- The General Affairs Director-General's Diagnosis, in conjunction with an environmental management audit, is conducted on divisions that the General Affairs Director-General deems necessary (divisions where environmental accidents occurred in the previous fiscal year, divisions that have significantly fallen short of their environmental targets, etc.).

- Environmental Management Meeting (twice a year)

- We hold "Environmental Management Conferences" for each manufacturing site and affiliated company in Japan to report on activity results and share issues, etc. We also hold "China Environmental Management Conferences" for affiliated companies in China to raise the level of environmental activities at each company.

- Activities in each region

- In each district, we hold district meetings on themes such as preventing global warming and energy conservation, where we report on the progress of activities, introduce case studies, and share information.

Strategy

Water risk assessment

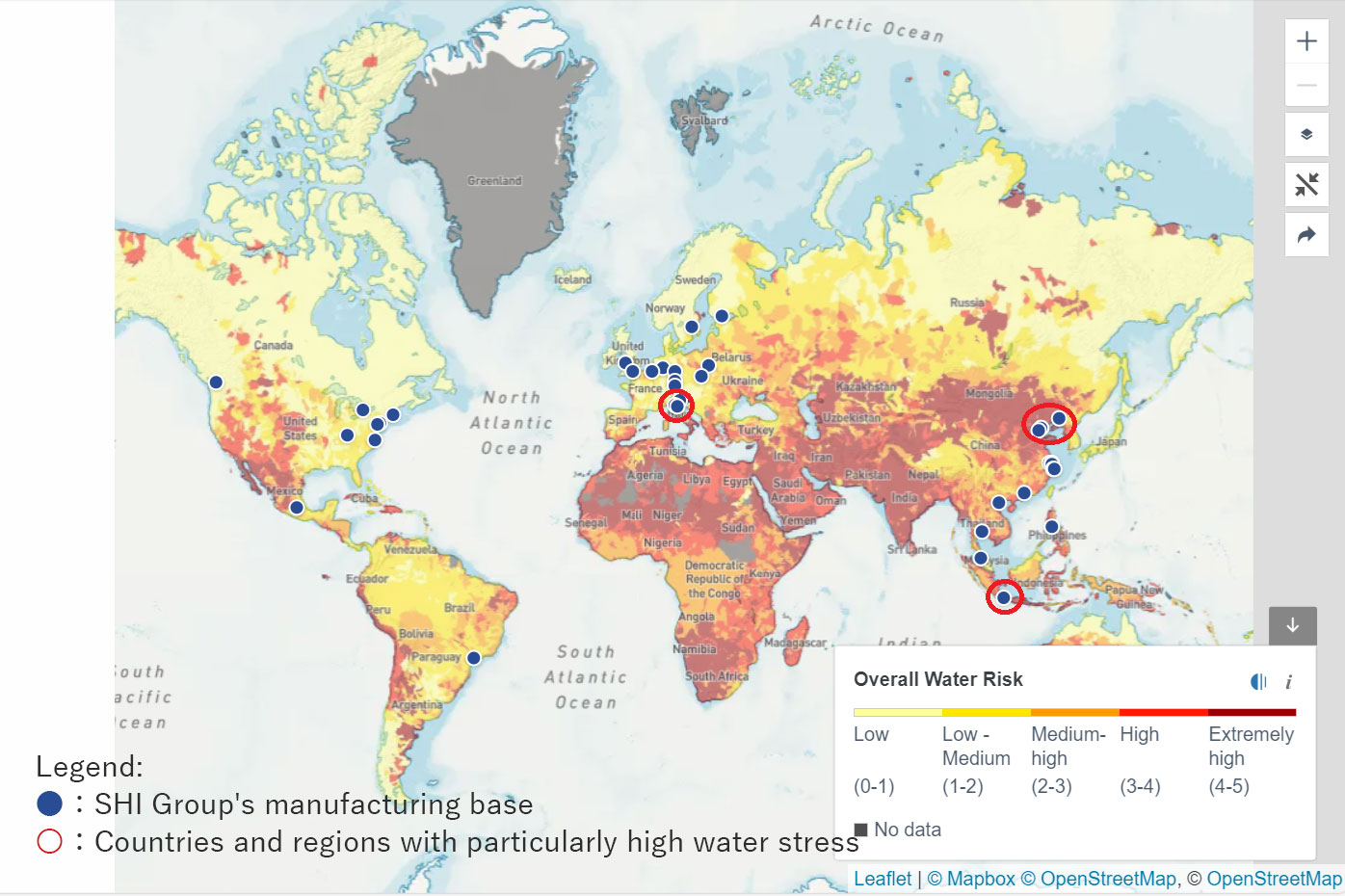

The Group is conducting water risk assessments at 57 manufacturing sites in Japan and overseas using AQUEDUCT, provided by the WORLD RESOURCES INSTITUTE.

As of fiscal 2024, there are five manufacturing sites rated as "High" or higher for "Overall risk," accounting for approximately 5% of the Group's total water withdrawals.

Taking the survey results into consideration, we will work to reduce water risks by reducing water withdrawals across the Group, promoting water recycling, and adapting to physical risks such as heavy rain and flooding.

In addition, we conducted a survey on water resource management among companies that account for 80% of the procurement value of raw materials in our supply chain. We received responses from approximately 80% of all suppliers, and of these, approximately 40% had already set targets and implemented management. Going forward, we will deepen communication through visits to suppliers and web conferences, and strive to share environmental issues and improve environmental stewardship.

SHI Group's manufacturing sites and water stress(Aqueduct Water Risk Atlas)

Measures

- Water quality management

- We set voluntary management standards that are lower than the discharge standards for sewers, rivers, oceans, etc., and manage the quality of discharged water by continuously conducting voluntary measurements and regular third-party analysis.

- Reducing water intake

- We are working to reduce water intake (reducing water usage) or use water efficiently by checking for and improving leaks, reusing cooling water, and promoting the use of rainwater.

Case studies

Our group formulates a medium-term environmental plan every three years and promotes activities accordingly. In the 7th medium-term environmental plan that began in fiscal 2024, we are working to reduce water usage, use it efficiently, and prevent pollution, while also considering biodiversity in addition to reducing the environmental impact.

- Checking and repairing buried water pipe leaks

- Storage of rainwater for irrigation of green spaces

- Recycling in cooling towers (chemical injection)

- Reuse of test water (storage)

- Oil cleaning in factories (to prevent water pollution)

Nihon Spindle Co., Ltd.

Rainwater storage tank (buried)

|

|

Shin Nippon Machinery Co., Ltd. Kure Works

Reuse of test water (storage tank)

Risk management

To prevent environmental accidents from occurring, we conduct regular environmental risk assessments at each of our locations.

In the unlikely event that an environmental accident does occur, we take appropriate measures, analyze the details of the accident, and share the information with all relevant departments in order to prevent the occurrence or recurrence of similar incidents.

For events that have not yet resulted in an environmental accident but have the potential to lead to an environmental accident in the future, we treat them as "environmental near misses" and work to strengthen our efforts to prevent environmental accidents from occurring.

The Risk Management Committee (held twice a year) identifies risks that could have a major impact on the Group, and evaluates the importance of each identified risk to the Group by assessing the frequency of occurrence and the magnitude of the impact when it occurs. The Risk Management Committee selects countermeasure departments for the identified risks, manages them appropriately, and oversees their progress.

Additionally, we have formulated a basic group BCP policy to strengthen our response to all types of disasters.

Metrics and Targets

The goals (Form 2024)

- Environmental Management

- (Global) Zero Major environmental incidents*1

- Reducing water withdrawal (reducing water consumption)

- (Japan) Below average value from 2020 to 2023

(Overseas) Below average value from 2020 to 2023 [per unit of sales]

Results

- Water Quality Management

- There were zero Major environmental incidents*1 at domestic and overseas bases in fiscal 2024.

We will continue to thoroughly manage water quality.

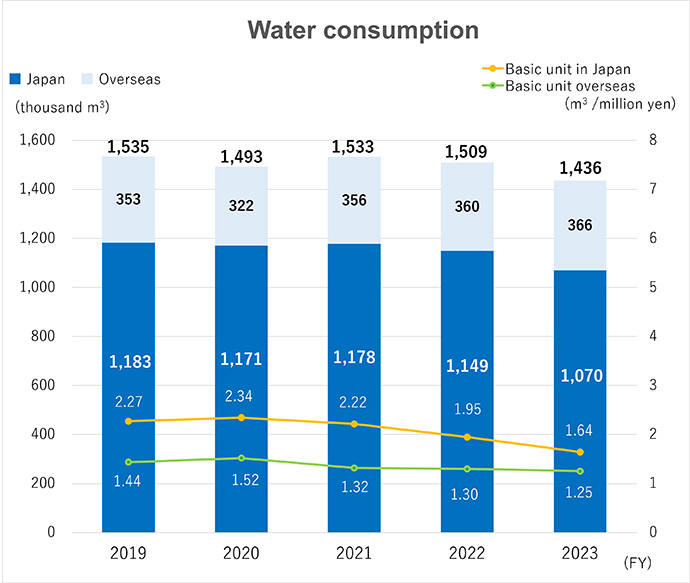

- Reducing water withdrawal

- Although FY2024 results show we fell short of our target as water intake increased 8.1% overseas, a 0.4% reduction was achieved domestically, meeting the target.

We will continue to set our sights on achieving our goal by endeavoring to use water more efficiently.

※1: Major environmental accidents are defined as cases where a fine (of $10,000 or more) is levied, administrative guidance issued, or other penalty assessed due to violation of a law, ordinance, or other regulation.

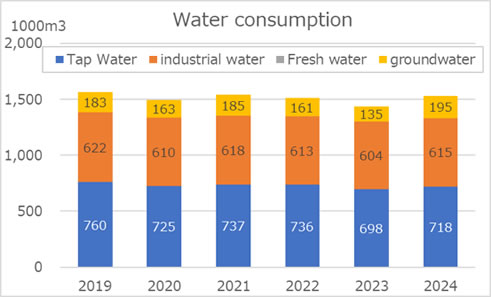

- Water consumption by water source (tap water, industrial water, surface water, groundwater)

- 2024 Consolidated Coverage: 78.3%

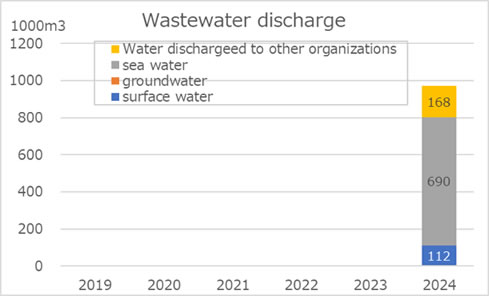

- Discharge (surface water, groundwater, seawater and water sent to other organizations)

- Data Scope: Domestic Production Sites