Customers

Basic Views

The corporate mission of the Sumitomo Heavy Industries Group is to contribute to the development of society through the provision of high-quality products and services. We believe that earning long-term trust from customers around the world leads to sustainable growth, enhances our corporate value, and enables us to meet the expectations of all stakeholders.

To ensure that customers across a wide range of industries can use our products and services with confidence and satisfaction, we have established quality assurance systems tailored to each product. These systems are supported by clearly defined operational processes, which we strictly follow to manage product quality and drive continuous improvement.

Quality Principles and Policy

- Quality Principles

- Through the continuous and unwavering pursuit of world class quality that is recognized globally, we will supply customers with products and services that they recognize as adding value to their business.

- Quality Policy

-

- Customer First:

Define quality targets based on the expectations of the customer - Continuous Progress:

Continuously advance the quality system and incorporate quality with a process mindset - Everyone Participates :

Every person involved in quality sets an objective and tackles quality issues head on as a team

- Customer First:

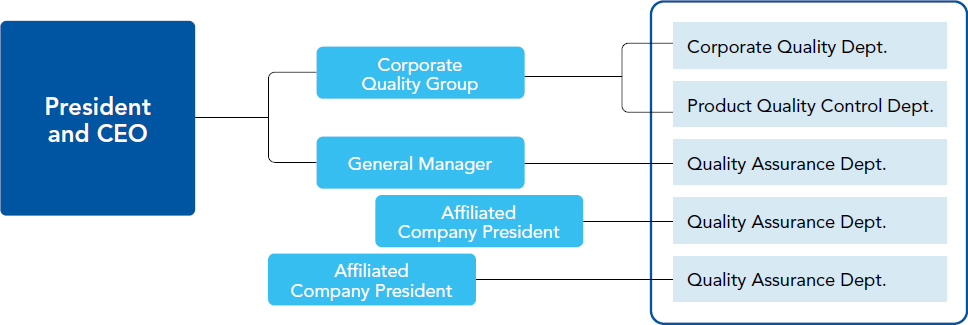

Quality Assurance System

Each division and affiliated company within our group has established its own quality assurance system tailored to its specific business operations.

To ensure independence, the quality assurance departments of each division and affiliated company report directly to their respective Division Heads or Company Presidents.

The Corporate Quality Group oversees product quality across the entire group.

Initiatives

- Process Review

-

Manufacturing site inspection by the President This is a forum where the President and CEO visits each division and affiliated company to conduct a review of operational processes.

Beginning with an assessment of the manufacturing site, the President, together with the Vice Presidents in charge of Head Office, engages in in-depth discussions with the division head, focusing on quality and manufacturing issues, and deepening the dialogue regarding problems and areas for improvement in the processes.

- Quality Assurance Department Managers Meeting

- This is a meeting hosted by the Corporate Quality Group and composed of quality assurance department heads from each division and affiliated company.

The purpose of the meeting is to share ideas, policies, and approaches for improving quality, foster mutual learning, and enhance organizational capabilities.

Ongoing, multifaceted discussions are held on the theme “From strengthening recurrence prevention to proactive prevention.” In addition, monthly exchanges of quality-related information are conducted, and customer relationships are continuously monitored from a quality perspective using the “Customer Satisfaction Indicator (KPI).” Regular discussions are also held to deepen consideration of improvements to this KPI.

- Quality Management System (QMS) Audit

- This is an initiative led by the Corporate Quality Group to verify the effectiveness of quality assurance systems on an annual basis.

We handle a wide variety of product types, and each division and product category has its own quality assurance system tailored to its business characteristics and operations.

Through the review of dissemination processes for quality manuals, quality regulations, procedural documents, and quality records, we assess both the effectiveness of the quality assurance system and the process capability of each operational procedure.

ISO 9001 certified: 96% of our group’s major manufacturing divisions (as of the end of FY2024)

- Strengthening Process Improvement Framework through Quality Control Training and Six Sigma Implementation

- We consider the assurance of product safety and quality to be a key priority that all employees should be deeply conscious of. In general, Quality Control Training will be conducted for all new employees (including new graduates and career hires) when they join the company.

As a shared approach to quality improvement across our group, we have adopted Six Sigma, an internationally recognized method for process improvement, and have continued to offer practical training in process improvement since 1999. To strengthen our processes, we train and assign "Master Black Belts" to oversee process improvement at divisions and affiliated companies, "Black Belts" to tackle complex problem-solving and provide guidance, and "Green Belts" to lead workplace-level problem-solving as project leaders.

As of the end of FY2024, the total number of certified Green Belts has exceeded 2,557, and the total number of certified Black Belts has surpassed 205. These efforts aim to elevate the overall level of process improvement.

- Rigorous Quality Compliance

- A section on “Prohibition of Inappropriate Conduct in Quality Control” has been included in our Compliance Manual, which outlines the various laws, regulations, and specific action guidelines that must be observed by our group’s employees in order to ensure that everyone in our group is fully aware of the importance of quality compliance.

In addition, we have been working to strengthen our quality control processes and quality audit system as well as enhance compliance through compliance training on an ongoing basis as part of our efforts to prevent the recurrence of inappropriate conduct in quality control that had taken place in the past.

- Promotion of Product Security Activities

- We strive to improve product quality in accordance with the following policy.

- The Sumitomo Heavy Industries, Ltd. Group (hereinafter referred to as “the SHI Group”) recognizes that ensuring the security of its products and services is a critical management priority, directly linked to reducing customer risk and ensuring safety. To enable customers to use its products and services with confidence, the SHI Group is committed to implementing, maintaining, and continuously improving the following initiatives.

- Compliance with Laws and Regulations

- All executives and employees shall comply with applicable laws, regulations, contractual obligations, and other relevant requirements related to product security.

- Establishment of a Product Security Management Framework

- The SHI Group shall establish and maintain a management framework to effectively promote and oversee product security initiatives.

- Implementation of Product Security Measures

- To prevent or minimize damage caused by unauthorized access or other threats to the confidentiality, integrity, availability, and other critical attributes of its products and services, the SHI Group shall implement security measures throughout the product lifecycle. These include embedding security into the design and development phases, providing vulnerability information related to its products and services, and conducting regular security assessments as appropriate.

- Incident Response

- In the event of a product security incident, the SHI Group shall promptly notify customers and relevant stakeholders of appropriate countermeasures through suitable communication channels. Subsequently, root cause analysis and corrective actions shall be undertaken to prevent recurrence.

- Education and Training

- The SHI Group shall provide product security education and training to executives, employees, and, as appropriate, business partners, to foster continuous improvement in product security awareness and practices.

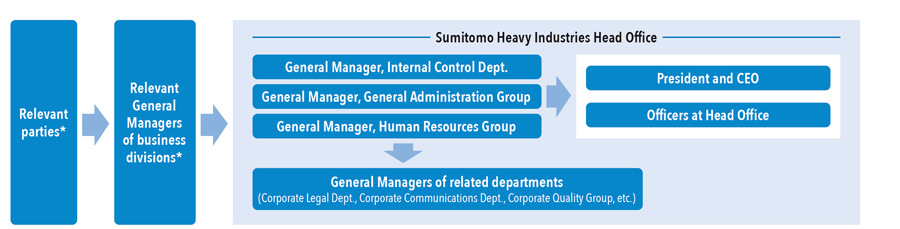

Reporting Flow in the Event of Product Accidents, etc.

To prepare for the possibility of serious accidents caused by the products our group delivered—such as fire accidents or accidents resulting in personal injury or fatality—we have defined a reporting procedure/flow in the Sumitomo Heavy Industries Group Emergency Contact Guidelines to help ensure prompt communication with our top management, the ability to obtain accurate information, and the ability to respond swiftly and appropriately.

- *This includes the Sumitomo Heavy Industries Head Office, Works, Branches, Business Divisions (including Japanese and Overseas Subsidiaries and Affiliates), and Subsidiaries and Affiliates (including Japanese and Overseas Subsidiaries and Affiliates) over which the Head Office has jurisdiction.