STAF (Steel Tube Air Forming)

Revolutionizing Automotive Body Structure

STAF (Steel Tube Air Forming) is the new forming system which can drastically reduce the weight of automobile body frame.

STAF is the new tube hot air blow forming process combines press and blow forming.

Strengthen, Lightweight, Simplify

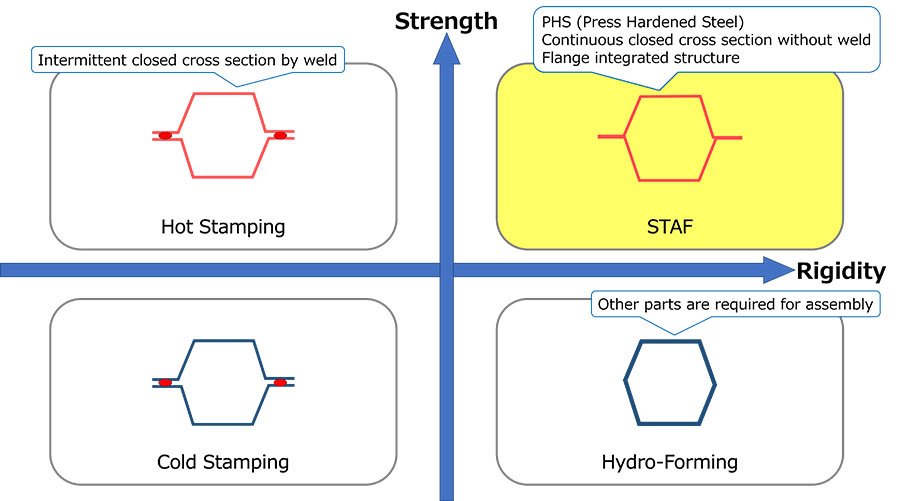

STAF achieves both unique continuous closed cross-sections with flanges and high material strength of PHS (Press Hardened Steel), and it contributes lightweighting and improving crash safety for automobiles.

Introduction

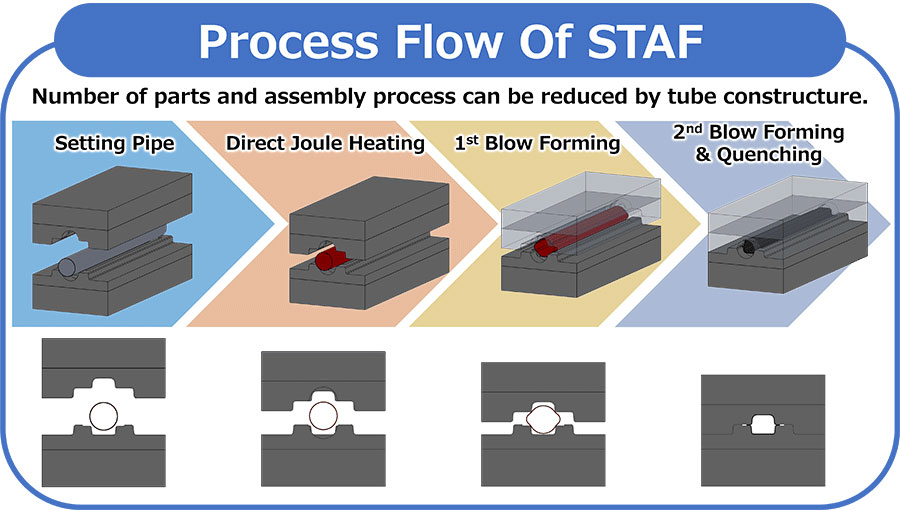

STAF (Steel Tube Air Forming) system is enables to form strong, rigid, and lightweight tubular parts by its simple process.

With the unique control system, setting the material pipe into the die and completes whole processes such as (1)Electrical Joule Heating ⇒ (2)1st Air Blow (Flange Forming) ⇒ (3)2nd Air Blow (Shape Forming) & DIE Quenching by one-pack.

- 1Electrical Joule Heating

Setting the material pipe into the die and chucking its edge by set of electrodes.

Processing electrical joule heating and rapidly heat the pipe.

Compared with heating method with furnace, it enables to improve energy efficiency and reduce running cost and environment load. - 21st Air Blow (Flange Forming)

After heating the material pipe, apply high pressured air into the inside of the pipe at the middle of die strokes with unique control technology, and form the flange.

- 3After 1st air blow, die completely closes and supplying high pressured air again and forming section shape accurately. Material is mated to the die surface and quenched. (Die Quenching)

STAF's Benefits

Lightweighting

STAF processed parts have both higher than 1500MPa material strength and continuous varied cross section and perform high rigidity. Compared with conventional hot stamping processed parts, it enables about 30% lightweight effect.

Strengthening

Flange portion processed by STAF can be used not only for assembly with other parts but also for controlling its deformation mode. STAF processed parts can be formed complex sectional shape and changed in the longitudinal direction of the pipe. These characteristics contribute to parts strength and rigidity performance improvement.

Simplification

STAF can unify the assembly part configurated multiple parts and enables to reduce the number of dies and processes. Direct electrical joule heating system (heating material pipe inside the die) can make the equipment very compact and drastically reduce capital investment cost.

Development Concept

Application

We recommend to apply STAF to automobile frame parts such as front pillars, roof side rails, roof rails, bumper beams, door impact beams, side sills and so on.

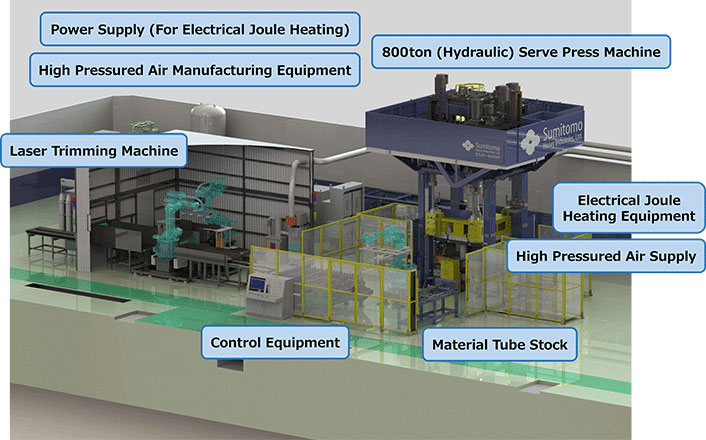

STAF prototype machine

We can offer prototype service with our actual STAF facility. Customers can use it for application development, prototype for mass production and actual evaluation.

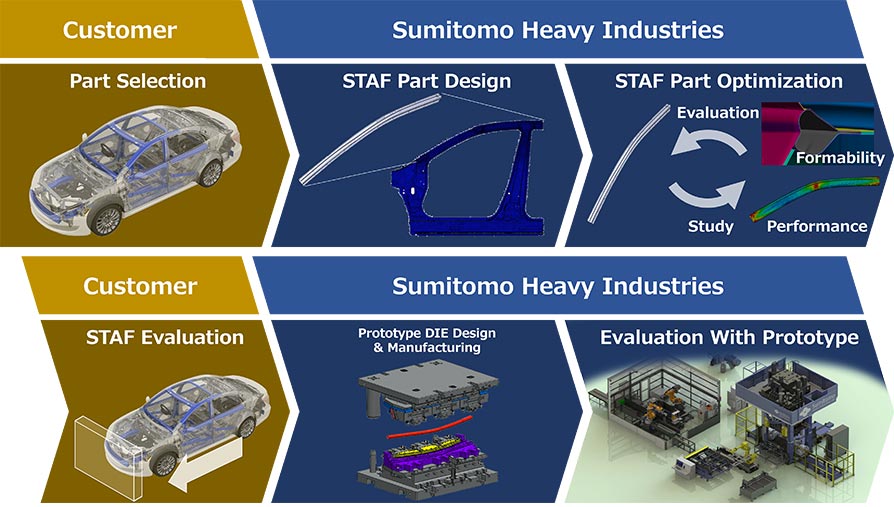

Application Engineering Support

Sumitomo heavy Industries can offer not only facilities design, manufacturing, sales and maintenance but also application engineering support required for customers.

- 1STAF Part Optimization

We propose optimized design for STAF part to maximize part performance.

- 2CAE Evaluation

We offer CAE evaluation service for part strength and formability.

After CAE evaluation, we can also offer prototype part processed with our trial STAF facility. - 3Facilities Optimization

We design the facilities optimized for customers’ request (factory layout, production volume, production plan etc…).

- 4Element Technology Development

We’ve been developing element technology for STAF. For customer’s smooth STAF application, we can offer required technology information.

For detailed information about the products please contact

Phone

STAF Project

E-mail Contact