Waste & Environmental Pollution Prevention

Basic Approach

SHI Group strives to curb waste and other emissions discharged during our business operations as well as to recycle and effectively utilize resources in an effort to reduce our environmental footprint. We have also imposed controls on VOCs as well as PRTR and other chemical substances.

Waste

Curbing Waste Emissions

We have established a waste (including hazardous waste) generation target of maintaining the basic sales unit at a level equal to or less than the 2020 to 2023 average.

In FY2024, we achieved a 24.5% reduction, enabling us to meet our target. As we review packing specifications and promote conversion of wood waste into raw material for manufacturing particle board, these and other initiatives will contribute to reducing emissions. In the future as well, we will promote waste reduction with a particular awareness of the 3R principle, including carefully separating waste and recyclable items.

We have also reduced waste emissions by 20.8% overseas, meeting our target as well.

Zero-Emissions (Landfill Rate Reduction)

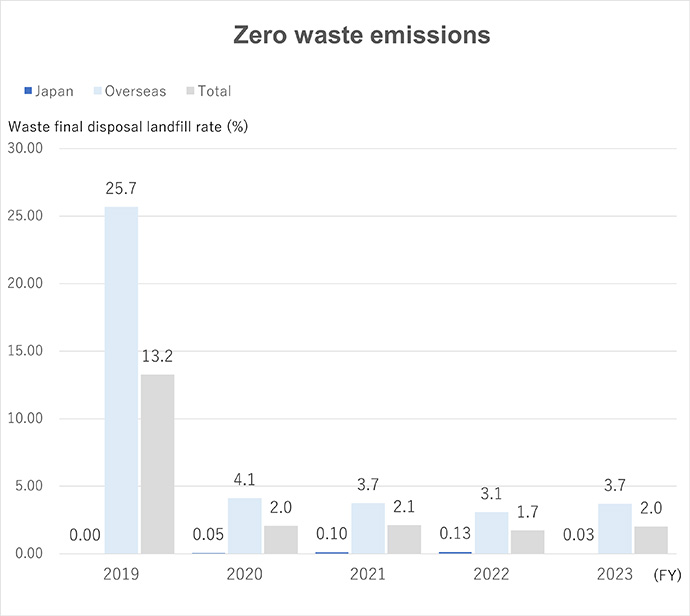

For Japan, SHI Group defines a zero-emission plant as one for which the ratio of landfill disposal volume to waste discharge volume (landfill rate) is less than 0.5%. Since FY2005, we have been promoting efforts to reduce landfill rates. In FY2024 , the landfill rate for all domestic works (6 works and 7 plants) and group businesses other than works (8 companies) was 0.08%. We have consistently achieved zero emissions in Japan since FY2011.

Furthermore, our landfill rate target for overseas is not to exceed 5% and we have been promoting activities that enable us to reach that goal. In FY2024, we achieved our target with a rate of 3.3%. Our combined domestic and overseas waste landfill rate was 1.8% in FY2024. Recycling is a key component of our efforts to achieve zero emissions, which we do by separating waste. As part of our aim to have our plants contribute to a sound circular society, we will also be meticulous about separating waste so that we are sure to maintain zero emissions.

Compliance with Act on Promotion of Resource Recycling Related to Plastics

SHI Group manages waste plastic using metrics for group-wide emissions and the amount of waste generated per basic unit of sales.

On a non-consolidated basis, SHI’s plastic waste emissions in FY2024 were 1,040t, a year-on-year decrease.

SHI Group will continue our activities to manage and reduce waste plastic across the entire group. We will promote the 3Rs (Reduce, Reuse, Recycle) plus renewable for plastic packaging materials and consider more comprehensive actions that even look at product components in our aim to engage in operations with a full awareness of the supply chain.

Plastic Product Reuse Initiatives

When considering how to dispose of the polycarbonate partitions used during the pandemic, the Osaki Head Office made the decision to recycle these rather than scrapping them. Approximately 161 kg was recycled, resulting in a significant contribution to the office’s efforts to recycle reusable plastic.

Prevention of Environmental Pollution

Complete Elimination of Organochlorine Chemical Use

We have continued to strive to completely phase out the use of dichloromethane, tetrachloroethylene, and trichloroethylene, organic chemicals subject to the Soil Contamination Countermeasures Act.

We have completely eliminated and banned the use of ozone-depleting substances HCFC-225 and HCFC-141b since FY2008 and FY2010, respectively. We have been promoting the scheduled replacement of R-22, production of which was discontinued in FY2020.

Control of VOC Substance Emissions

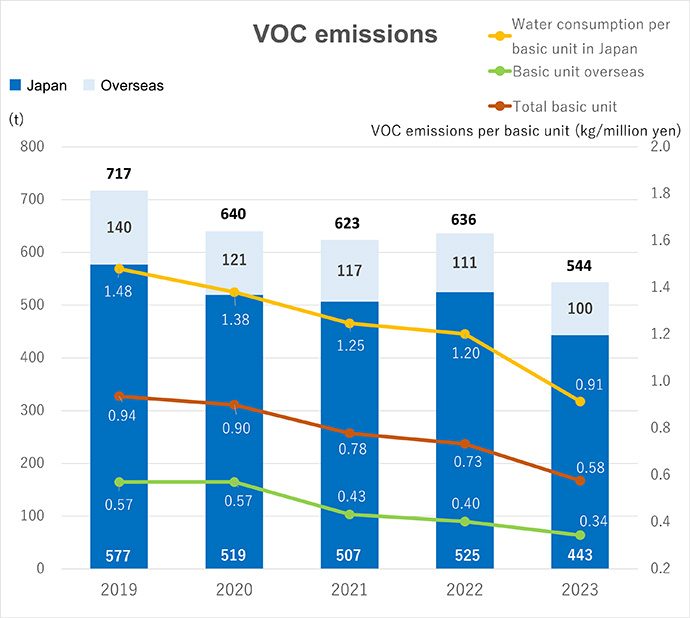

Toluene, xylene, and ethyl benzene contained in paint solvents account for at least 90% of VOC substances used by SHI Group in Japan. With our 7th Medium-Term Environmental Plan, we set a target of keeping VOC emissions below the average for the period from FY2020 to FY2023. In FY2024, we achieved a 6.1% reduction and a 16.6% decrease in the amount generated per basic unit of sales.

We will continue to expand the scope for employing low-solvent coatings and cleaning agents that do not contain VOCs, as well as for the use of powder coatings, in addition to further enhancing painting efficiency so that we may reduce the amount of paint and other substances used.This will bolster our endeavors to reduce emissions of these substances.

PRTR Substance Emissions and Transfer Volume

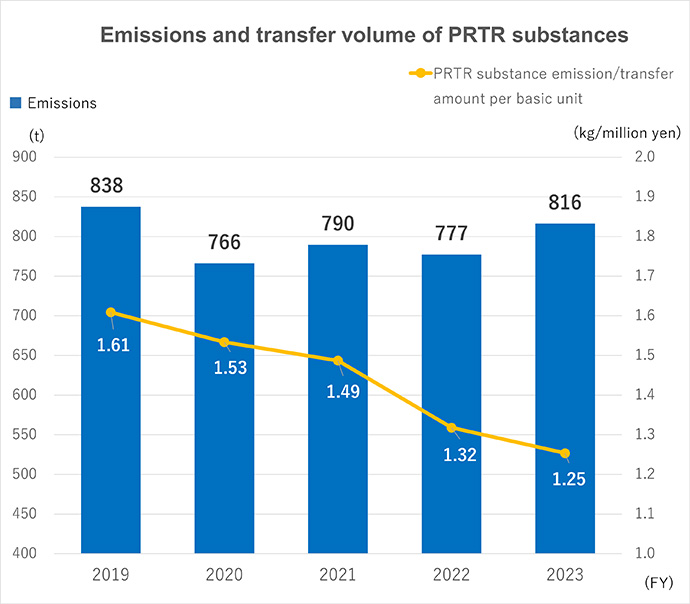

Paint solvents toluene, xylene, and ethyl benzene comprise 90% or more of all PRTR substances. Despite total volume increasing in FY2024 year-on-year, the level amounted to a 4% reduction compared to the average for the period from FY2020 to FY2023. In addition, we achieved an 8% reduction when measured in the amount generated per basic unit of sales.

While maintaining quality, we will expand the application of low-solvent paints as well as establish and expand solvent recovery and removal equipment so that we may reduce emissions and transfer volume.

PCB Management and Complete Elimination of Equipment Using PCBs

All devices containing high concentrations of PCBs were registered early on with the waste-disposal company Japan Environmental Storage & Safety Corporation. These devices have been systematically detoxified pursuant to the Act on Special Measures Concerning Promotion of Proper Treatment of PCB Wastes. Transformers containing PCBs and stabilizers for lighting equipment containing PCBs have been replaced or updated gradually. Some Works and affiliated companies have completely disposed of all PCBs. Additionally, we have completed our survey to identify equipment containing low concentrations of PCBs, and have been working to detoxify such equipment step-by-step before the deadline.