Injection Molding Machines

Next advancement in molding

Sumitomo Heavy Industries launched the injection molding machine industry in 1965. Since then, we have been developing technologies that have been leading the industry, such as all-electric machines equipped with the industry's first direct drive system and the revolutionary integration application “Zero-molding.” Our strength includes our robust lineup and precision/high-cycle molding, which contribute to the production of a wide variety of plastic products.

Click here for detailed information about Injection Molding Machines

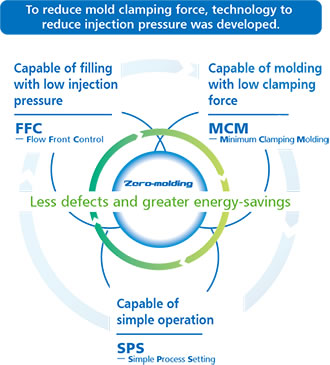

Zero-molding

Getting as close to zero defects, losses, and faults as possible

Zero-molding is an integration application that achieves as close to zero defects, losses, and faults as possible.

This application consists of three elements, including MCM (mold clamping-related technology), FFC (filling-related technology), and the system SPS that easily operate these technologies.

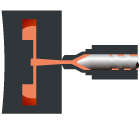

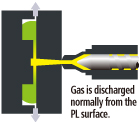

MCM(Minimum Clamping Molding)

Reduce the maintenance work to utilize the vent effect and extend the mold life

Vent is clogged by excessive mold clamping force.

It can result in short shots and gas burns.

Gas is properly discharged from the PL sides.

It resolves short shots and controls mold deposits.

FFC(Flow Front Control)

Low pressure and smooth filling promote venting, improving the cavity balance

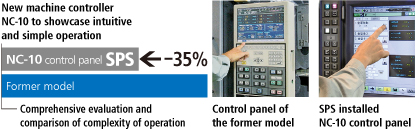

SPS(Simple Process Setting)

Error-free simple settings reduce preparation/operation time

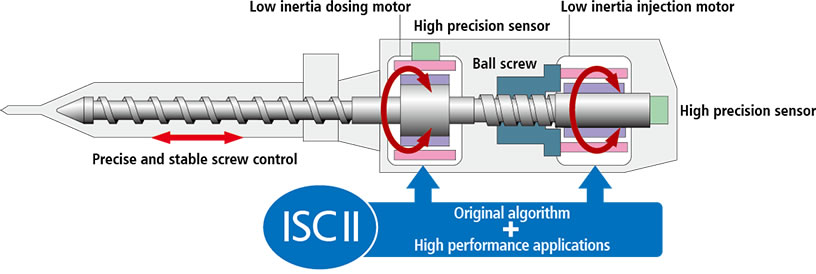

Direct Drive System

High precision and highly responsive screw control

Screw control is highly responsive thanks to a structurally original injection system and low inertia servo motor.

Moreover, plasticization, filling and pressure holding are precisely and stably controlled by an in-house developed algorithm, which helps to lower injection pressure and improve cavity balance.

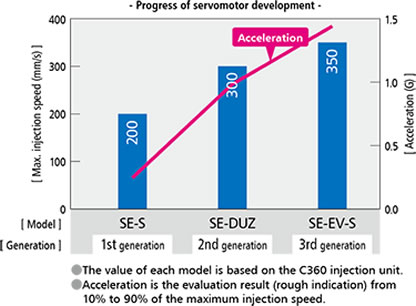

Toward the third generation of development

SE-S, which was released in 1997 and was the industry's first machine equipped with the direct drive, instantly and solidly established Sumitomo's all-electric technology.

The direct drive system symbolically represents the developmental philosophy of the all-electric technology and the wide range of the technical capabilities.

The direct drive directly communicates the required movements without going through unnecessary speed reducing devices between the servo motor and actuator. The drive has continued to evolve through enhanced low inertia moment and speed acceleration, and it is now in its third generation.

The performance has been significantly improving.

Product lines

Standard/High Speed

Horizontal/Small

Specializes in small-sized precision

Electric small-sized injection molding machine with an advanced direct drive mechanism, which features high horsepower and high responsiveness

Mold clamping force: 170kN

Horizontal/Middle

Double-shot machine

Special purpose machine

Cleaner environment with electric machines

Providing unequaled quality and reliability with injection blow and mold technology

Mold clamping force: 1300kN

Further energy conservation

Electric PET pre-form molding machine developed for mass production of beverage

Mold clamping force: 5000kN

For detailed information about the products please contact

Phone

Sales & Service Headquarters, Plastics Solutions SBU

Engineering and Sales Division

Web

Plastics Solutions SBU