Zero-molding for fast cycle

Specially equipped with a linear guide and anti-shock leveling pads ideal for fast cycle molding,

with a focus on Zero-molding to improve consistency of production. Thin-wall, fast cycle and stable molding realized.

The apex of stable and fast-cycle molding

Fast cycle molding far surpassing the performance of conventional models, thanks to improved injection speed, better responsiveness,

shorter process time, and precise control. Machine high performance enables comfortable,

fast cycle production.

Zero-molding, first time introduced as standard feature,

has won “tender and easy” to molds widely.

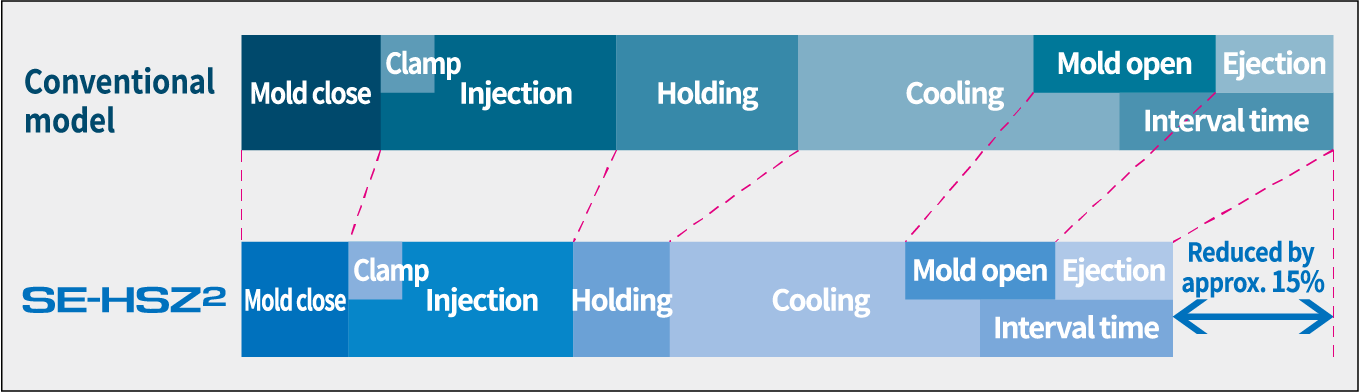

Achieves an average of 15% cycle time reduction when compared to conventional model through improved injection speed,

FFC molding, and faster mold open and close via ISC. For FFC (flow front control) molding,

extra

holidng time previously required to prevent sink marks can now be reduced to zero, which contributes to productivity.

ISC (intelligent servo control) system for improving productivity

Faster mold open/close realized, reduced machine vibration, and improved molding stability through use of a new control algorithm.

Improved servo control performance reduces variation in cushion position and peak pressure,

enabling precise plasticizing, filling, and holding process.

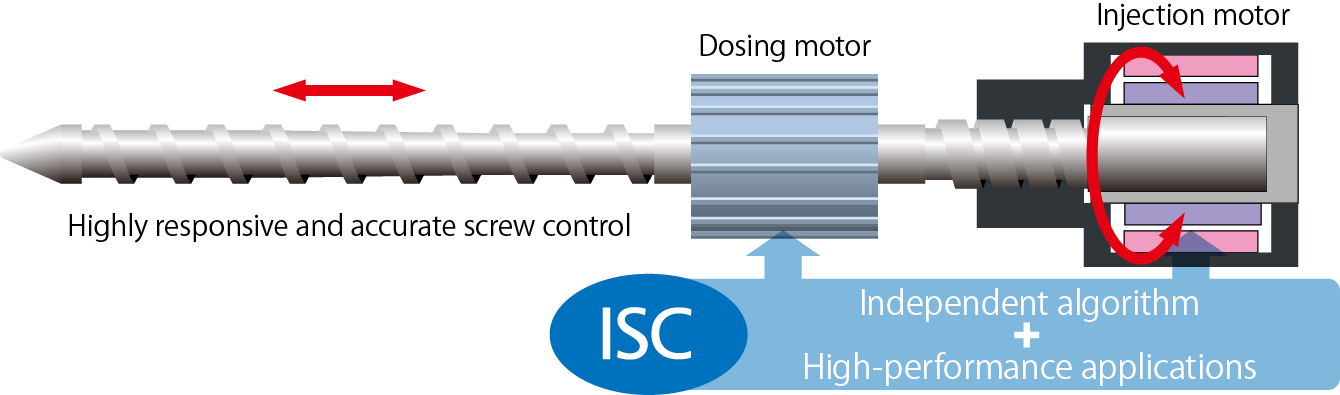

Direct drive that realizes precise fast cycle molding

The injection unit utilizes a unique Sumitomo direct drive mechanism.

Approx. 2.5 times faster injection velocity response than belt driven type.

Enables more precise fast cycle molding, as high speed and pressure

can be

controlled instantaneously.

Injection unit from C1250 to C1700 utilized a double-axis synchronized

direct drive mechanism with compact design, in order to achieve

higher response performance.

First-generation servo motor (stator)