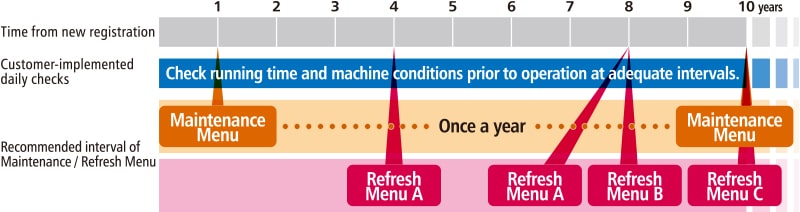

Beside annual standard maintenance menu, there is a refresh menu applicable in fixed interval of time. By combining with regular maintenance, refresh maintenance helps in keeping stable and secure production.

- Every

4 yearsRefresh Menu A

- Inspection and replacement of CPU fans, NC unit fans, motor fans and encoder batteries

- Every

8 yearsRefresh Menu B

- Inspection and replacement of NC unit electrolytic capacitors and contacts for motor drive power

- Every

10 yearsRefresh Menu C

- Replacement of CPU cards, etc.