Process Pumps

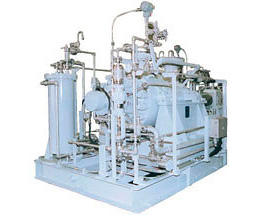

Proprietary technologies applied in response to evolving industrial infrastructure The process pumps of the SHI Group play an important role in transferring raw materials during manufacturing processes.

The process pumps of the SHI Group play an important role in transferring raw materials during manufacturing processes, as well as products in the petroleum refinery, petrochemical, oil and gas markets. High reliability is required of these pumps, as they are operated under harsh conditions at all times, ranging from high temperatures to extreme low temperatures, as well as high pressures and low pressures, while in highly corrosive environments. The SHI Group has been delivering these pumps to key customers throughout the world, with delivery records for about 25,000 units in about 60 countries.

Click here for detailed information about Process Pumps

Features

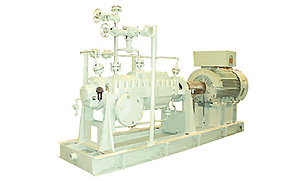

Vertically split multiple stage double casing center impeller type pumps (BTBF type)

The BTBF type pumps are horizontal types, vertically split, multiple stage, single inlet (double inlet in the first stage for BTBFD), double casing, diffuser guide vane, center line support, center impeller type barrel pumps.

The BTBF (BTBFD) type pumps are suitable for high pressure, high temperature and high speed environments (low NPSH with BTBFD) and can be used in a variety of harsh processes and industrial fields.

- Heavy duty pumps that comply with API610.

- Sealed chamber

Designed to dimensions that comply with API682 and API610. Dual seals can be fitted with standard dimensions of the SHI Group.

- Easy maintenance

These pumps can be overhauled without removing the main pipes or the drive units.

- High reliability

- Self venting

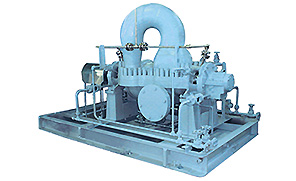

Double casing diffuser upright pumps (CZ type)

The CZ type pumps are double casing, diffuser, multiple stage, upright pumps (API Class VS6). When the external casing is removed it becomes a submerged type pump (API Class VS1).

The CZ type is suitable for a low NPSH, as well as low temperatures and can be used widely in a variety of processes and industrial fields. NPSH can be adjusted with the addition of a column section.

- These are heavy duty pumps that comply with API610.

- Designed to dimensions that comply with API682 and API610. Dual seals can be fitted with the standard dimensions of the SHI Group.

- Space saving with easy installation.

- Easy maintenance

A spigot joint type flange joining structure has been adopted for the head, outer case, ball, and column, to facilitate easy maintenance.

- High reliability

Stable operation is achieved through the optimized design of the drive unit bearing stand and pump case.

Product lines

For detailed information about the products please contact

Phone

Shin Nippon Machinery Co., Ltd.

Web

Shin Nippon Machinery Co., Ltd.