CO2 Reduction Measures

Basic Approach

SHI Group recognizes that responding to climate change is a key challenge in managing our environment. Of the strategies we are implementing to reduce our environmental footprint across all business activities including product lifecycle, our top priority has been to reduce CO2 emissions.

Each month, the Environmental Management Division supervises results achieved by each business division and provides feedback to those in charge. In addition, these results are reported to management three times a year at meetings of the Executive & Operating Officers Committee. SHI Group divisions promote climate change adaptation by mobilizing all personnel in these efforts, making sure their activities are visible, and implementing them to improve various processes so that the outcome is more efficient utilization of energy.

Scope 1, 2

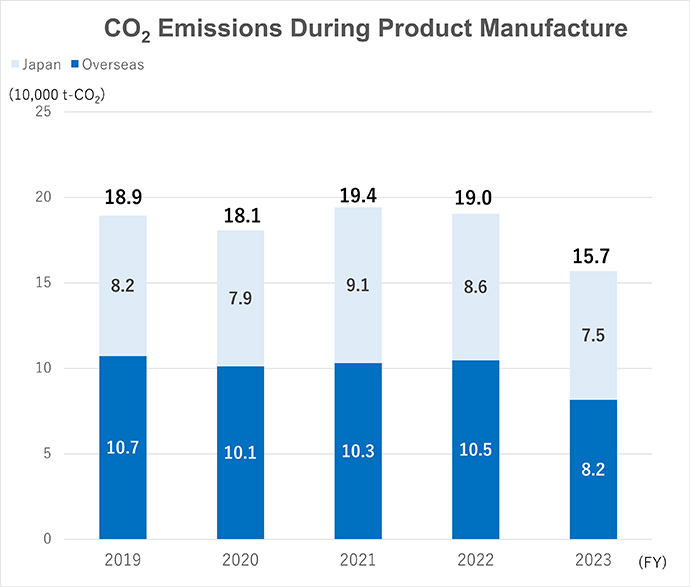

Reduction of CO2 Emissions During Product Manufacture

SHI Group’s CO2 emissions during product manufacture decreased approximately 2.1% against our target of reducing CO2 emissions equivalent to 1% of FY2019 CO2 emissions. ※

Although decreased semiconductor demand and other factors scaled down operations, the formulation and implementation of CO2 reduction plans adapted to each of our businesses has had a visible effect.

We will continue to take a proactive approach that includes updating to more energy efficient equipment, optimizing facilities, and cooperating with our engineering divisions to re-examine measures for reducing CO2 emissions. We will also be promoting the same level of activities on a global scale.

※Baseline: Amount equivalent to 1% of FY2023 CO2 emissions minus FY2019 CO2 emissions

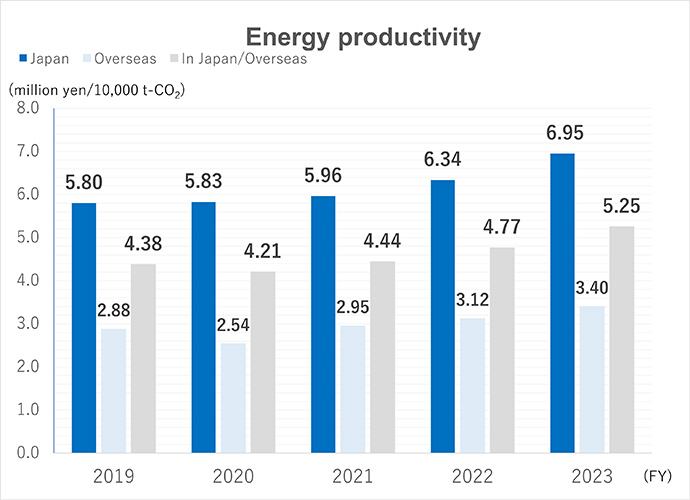

Improvements in Energy Productivity

SHI Group sets and manages metrics not only for CO₂ emissions but also for energy productivity (sales/CO₂ emissions) to improve production efficiency and reduce emissions. In FY2024, we set a target of a 1% improvement over the FY2023 level. While overseas emissions decreased by 9.2%, primarily due to lower demand in China and other factors, domestic sites achieved the target with a 2.7% improvement.Under our ongoing initiatives, we will continue to aim for further improvements in production efficiency by proactively investing in energy-saving equipment, and by promoting operational energy-saving measures. These include implementing company-wide simultaneous shutdown days, upgrading to high-efficiency equipment, and reducing standby power consumption across equipment and facilities.

Adoption of Renewable Energy

SHI Group has promoted adoption of renewable energies. Since 2020, we have proceeded to install solar power generation systems at new buildings of our SHI Group plants. In FY2024, an additional 2,294 MWh became available for a cumulative global capacity equivalent to 6,396 MWh.

We are continuing to actively set up systems both in Japan and around the world to achieve our intermediate benchmark of a 50% reduction by 2030 in comparison to FY2019 of CO2 emissions during product manufacture. In addition, we have also planned purchases of renewable energies. In FY2024, these purchases amounted to 84,567 MWh globally. The scale of these purchases is determined by taking into consideration the installation of solar power generation systems chiefly for new buildings and the reduction in CO2 emissions of 1% annually through a variety of energy-saving measures. We are promoting CO2 emission reductions with the aim of being carbon neutral by 2050.

Scope 3

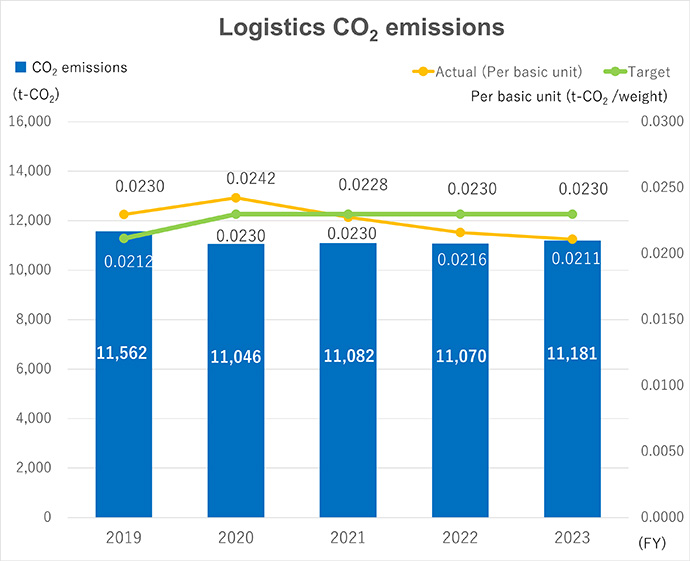

Promotion of Green Logistics

SHI Group is endeavoring to eliminate waste and enhance efficiency in product transport in order to reduce CO₂ emissions. In FY2024, we achieved our domestic target of maintaining the basic unit of shipping (t-CO₂/weight) below the average level recorded from FY2020 to FY2023, with a 3.2% reduction.Under the 7th Medium-Term Environmental Plan as well, we will continue to improve and optimize load factors, promote modal shifts, and effectively utilize mixed-load shipments to further advance our efforts.

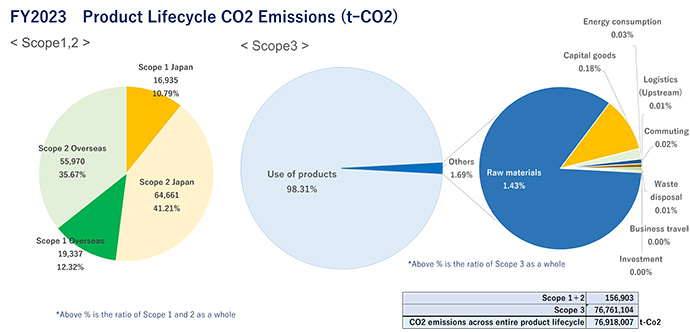

CO2 Emissions (t-CO2) Across Entire Product Lifecycle

In FY2024, product lifecycle CO2 emissions amounted to 67,390,000 tons, of which CO2 emissions during product use accounted for 98.0% or 65,887,000 tons. To reduce CO2 emissions across the product lifecycle, we recognize that increasing the number of and providing products that deliver outstanding resource and energy savings (Sustainability Plus Products) is an important business challenge for us in addressing climate change. We are actively improving our products, developing applicable technologies, and making other efforts so that we may offer even more of these superior products.

In addition, we are also focusing on building a cooperative framework with our suppliers to extend coverage of CO2 emissions associated with raw material procurement, which is categorized as Scope 3 and has the second-highest ratio of emissions after CO2 emitted during product use.

Carbon Footprint

SHI Group calculates the carbon footprint of plastic injection molding machines, cryopumps, and construction machinery excavators as finished products independent of our other main products.

Going forward, we plan to expand the range of products subject to carbon footprint calculation and prepare detailed calculations for leading models.

Endorsement of Japan Climate Initiative

SHI Group has endorsed the message of the Japan Climate Initiative (JCI): “Now is the time to accelerate renewable energy deployment: Calling for stronger climate change action in the midst of the fossil energy crisis.” So that we may be a world leader in striving to achieve the 1.5°C target, we will accelerate our own activities to increase energy efficiency and renewable energy use as well as strengthen collaboration with non-state actors domestically and internationally as part of our efforts to bolster initiatives that contribute to achieving net zero CO2 emissions by 2050.