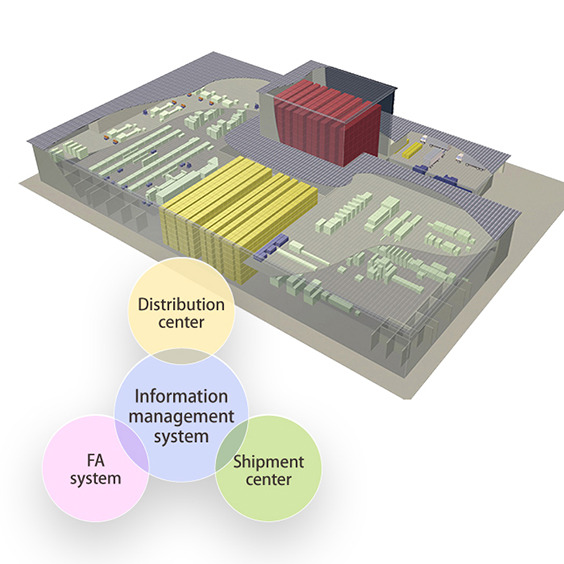

Logistics Systems

SHI Group solves customer's various logistics issues by reliable technologies and engineering.

SHI Group solves logistics problems in a wide variety of industries, from FA to distribution, with its reliable engineering technology supported by rich experience using the latest information management systems.

Click here for detailed information about Logistics Systems

Features

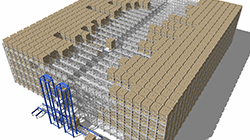

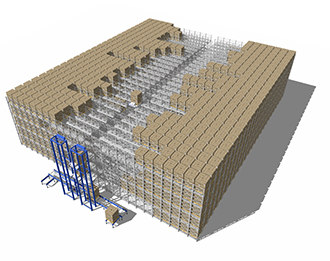

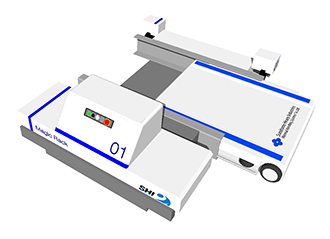

High density storage solution

The innovative automatic warehouse system "Magic Rack" achieves effective utilization of space and manpower/labor saving of pallet handling work.

- Coordination with various systems

- This system coordinates with logistics systems, such as autonomous transportation systems(AGV/AGF), picking and automatic sorting systems and can be applied to a wide variety of operations.

- Effective utilization of space and reduction of construction cost

- Overwhelming storage efficiency and flexible layout performance allows you to thoroughly utilize the space in the existing warehouse.

You can also control the building height when building a new warehouse, contributing to the reduction of construction cost.

- Labor saving in forklift work

- By reducing the forklift work within the storage area and conducting continuous automatic storage/retrieval and assortment 24 hours a day, this system can achieve work-style reformation on logistic sites.

- Smooth shipment with automatic assortment work

- You can conduct assortment work in advance in preparation for the outgoing schedule on the following day by using the night time and other off-hours, thus reducing the wait time for trucks and forklift work.

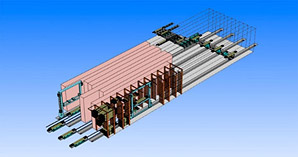

Advanced film plant solutions

The SHI Group ensures the safety of workers and the quality of products through full automatic transport, attachment and removal and storage of rolls in the clean environment.

- 1Ensuring safety through automatic interfaces with production machines

Unmanned operations are possible through automatic interface with production machine using RDRV.

- 2Ensuring product quality

Shaft hanging roll automatic warehouse and RDRV enables roll handling without human contact. It ensures product quality by reducing abrasion powder generated during storage, transport, attachment and removal.

- 3Easy to expand and flexible to handling styles

The RDRV transport and roll transfer method enables flexible adaption to the expansion and roll style changes in the future.

- 4Easy identification of the defect source and clarification of the affected range.

RMeS (Roll Management system) identifies the sources when defective products occur, and clarifies the affected range.

Heavy goods transport solutions

The SHI Group utilizes its automatic crane technology based on solid performance, and provides safe and reliable onsite logistics.

- 1Safe and reliable handling of heavy goods

The SHI Group provides safe and reliable handling of heavy goods by utilizing its technology supported by solid performance in the processes where transport, reloading, and storage are required.

- 2Contributing to securing quality

Reduces damage to products by utilizing our storage and transport technologies.

e-Commerce and Distribution Solutions

The SHI Group has built a logistics center that provides high productivity and shipping accuracy, capable of adjusting to diverse needs and fluctuation of daily shipping volume.

- 1Flexible to shipping fluctuations.

Appropriate inventory and replenishment are possible through BEST eS (integrated logistics management system) and Active Face Picking System (AFPS) to respond to shipping fluctuations.

- 2Shorter shipping lead time

The shipping lead time can be shortened through efficient allocation and sorting with seamless picking and Matrix Assort.

- 3Easy to expand and flexible to packaging styles

Accurate work instructions and inspection systems with BEST eS (integrated logistics management system) help prevent operator error.

- 4Easy identification of the defect source and clarification of the affected range.

High productivity can be achieved through Active Face Picking System(AFPS),Matrix Assort, controlled by BESTeS(integrated logistics management system).

Product lines

- *Active Face Picking System, RDRV, Circ Liner, and Matrix Assort are the registered trademarks of Sumitomo Heavy Industries, Ltd.

For detailed information about the products please contact

Phone

Sumitomo Heavy Industries Material Handling Systems Co., Ltd.

Logistics Systems

Web

Sumitomo Heavy Industries Material Handling Systems Co., Ltd.