Distillation & Liquid-Liquid Extractor

For the global environment, with distillation and extraction technologies

Distillation / Extraction plant we delivered is operated in various industries, especially the chemical industry, to separate and purify the components from liquid mixture.

We contribute your business with not only our high-performance equipment and/or the internals but also EPCC (Engineering, Procurement, Construction and Commissioning) services of the Distillation / Extraction plant.

Click here for detailed information about Distillation & Liquid-Liquid Extractor

Features

The energy-saving and high-performance distillation system, proposed with expertise of engineering and abundant experiences on distillation system.

We propose our solution for new installation project, expansion project or debottleneck project of distillation plant, optimizing process design with process simulation from basic design phase.

Of course, we study distillation column specification as main equipment and other equipment also such as re-boiler and condenser basing on the optimized process design, and furthermore we offer total EPCC service of the plant, including civil, piping, equipment, electrics and instrumentation.

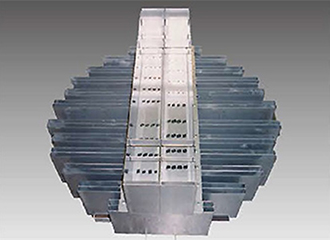

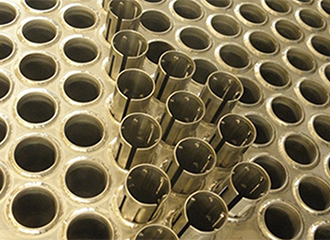

SFLOW – structured packing with excellent performance

"SFLOW", the structured packing from Sumitomo, achieves excellent separation performance over a wide range of process, from low liquid throughput to high liquid throughput due to a special surface treatment and structures. We manufacture our SFLOW under strict quality control in our own factory in Japan.

We propose optimized equipment with our SFLOW or combining SFLOW, trays, and random packings, suitable for the process.

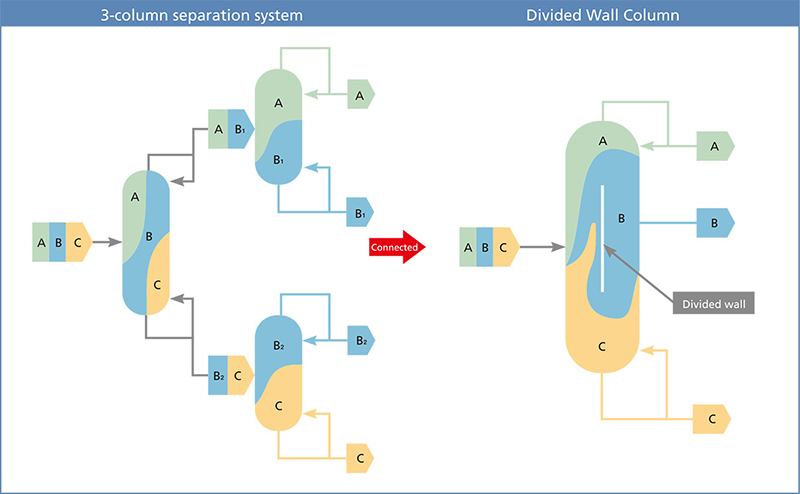

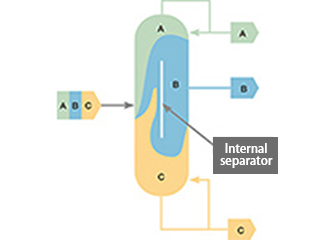

Column-In-Column – energy-saving column with dividing wall

We developed Column-In-Column which achieves energy-saving distillation system for multicomponent separation process. Comparing with the conventional column system which requires multiple columns for multicomponent separation, CIC system simplifies the process flow and decreases equipment quantity, energy, space, piping, instrumentation etc, and accordingly reduce both initial and running cost.

Product lines

For detailed information about the products please contact

Phone

Sumitomo Heavy Industries Process Equipment Co., Ltd.

Web

Sumitomo Heavy Industries Process Equipment Co., Ltd.