Coke Drum & Pressure Vessels

Structural design and manufacturing technologies, based on our extensive track record and experience, have been implemented with an advanced quality assurance framework to cater to a wide range of customer needs.

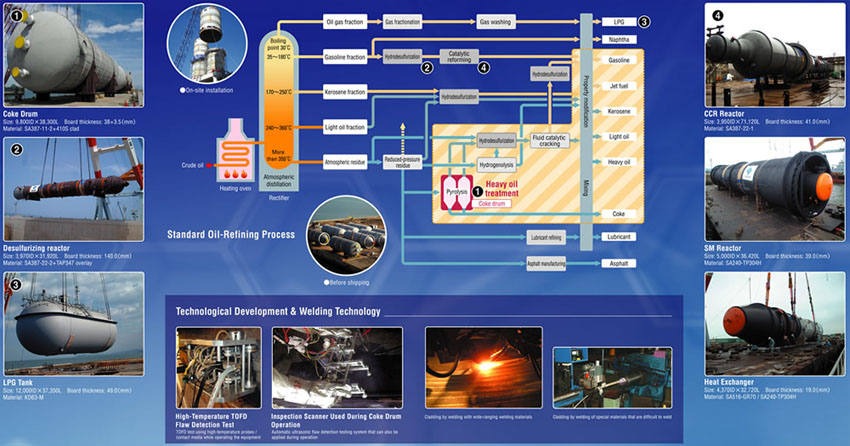

In oil refining, coke drum equipment processes heavy crude oil in the most efficient manner. In response to a growth in demand for gasoline, kerosene, and even jet fuel, coke drums are used to produce light oils and petroleum coke by thermally decomposing residual substances after the light constituents have been extracted from the crude oil. Light constituents can be used as raw materials for gasoline or the like, while coke can be used as fuel for generating electric power.

Click here for detailed information about Coke Drum & Pressure Vessels

Features

- 1Technical development and optimized designs with consideration for harsh operating conditions

The coke drum rapidly heats up crude oil, a raw material, and operates in the high temperature region near 500℃. It is then rapidly cooled to room temperature with cold water. Since it is operated under such harsh operating conditions, cracks and deformities tend to occur on the main body portion and it is usually necessary to suspend operations for repairs or replacement. A selection of materials with specifications less likely to cause cracks and deformities, as well as optimized designs in terms of dimensions and shapes, are proposed based on our extensive past experience and track record, in order to meet the customers' need for a long product life.

- 2Advanced welding process technology and quality control

Clad steel plates, comprised of heat resistant steel and stainless steel plates, are used to manufacture coke drums, since they are used at high temperatures. Because the diameter is large in relation to the plate thickness of the main unit, the manufacturing difficulty is considered to be higher than for other reaction containers. Welding and assembly with technologies and skills of a higher level are necessary for this reason. Furthermore, non-destructive inspections (radiographic tests and ultrasound tests, etc.) are applied to the welded sections in efforts to improve the reliability of the equipment.

- 3Inspections and diagnosis, as well as monitoring of equipment during operations

It is important to prevent any unscheduled emergency suspension of operations by detecting problems early, such as cracks in the main unit of the coke drum, by taking appropriate action during operations. Monitoring, by applying heat sensors and other means, is performed in order to respond to such needs, to ensure that proper operating conditions are maintained. The SHI Group also offers a range of periodic inspections as checkups, as well as repair services.

Product lines

High quality and highly durable products that provide peace of mind to our customers.

For detailed information about the products please contact

Phone

Chemical Machinery Division

Web

Sumitomo Heavy Industries Process Equipment Co.,Ltd.