All-electric Double-shot Injection Molding Machine

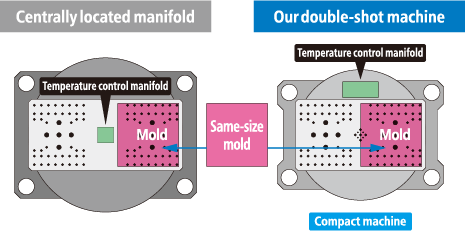

Piping routed to support greater freedom of molds

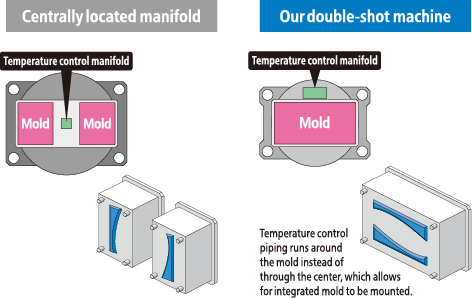

Since the manifold is not placed in the center of the rotary table, there will be no

wasted space.

This allows to mount the same size mold to smaller machines and leads to the

achievement of

“big jobs with a small machine” through an efficient mold use.

Long parts available thanks to wider range of mountable molds

An original temperature control manifold and wider tie-bar

clearance enable large mold to be mounted.

It enables the molding of long parts, which was not possible

with the separate (two-part) mold.

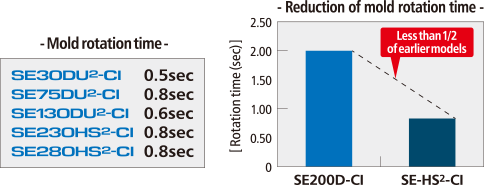

Greatly shortened mold rotation time

Rotating time has been reduced to less than half of the earlier model SE200D-CI,

leading to significant improvement in productivity.