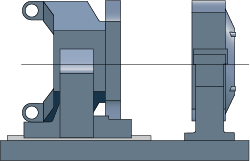

Platens keep high parallelism

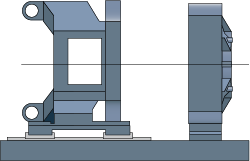

Conventional Platens

Heat flow model

Temperatures differ above and below the platen

because heat propagated to the frame.

Deformation accentuating model

Deformation is uneven across the platen, so the platen does not stay flat.

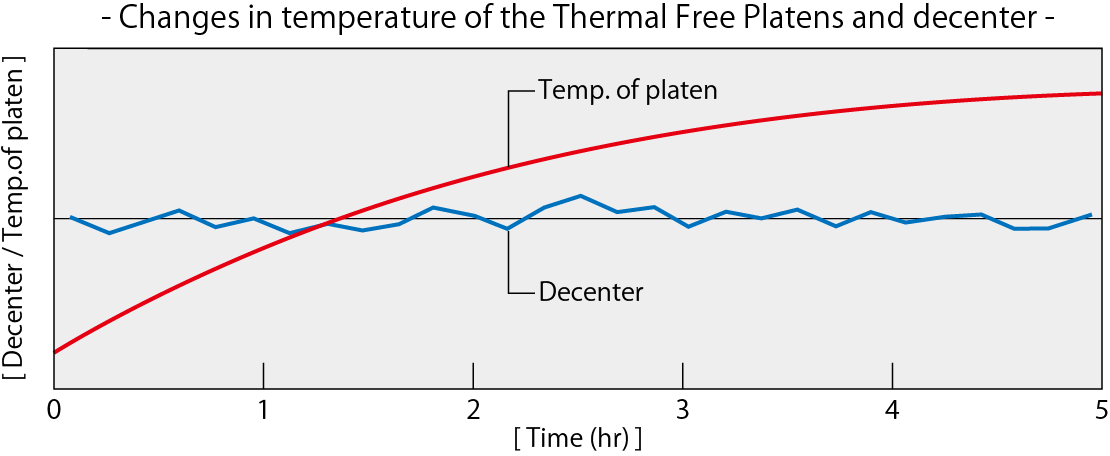

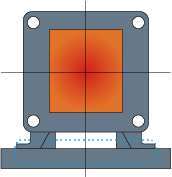

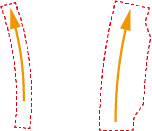

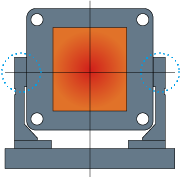

Thermal Free Platens

Heat flow model

Heat propagates symmetrically upwards/downwards.

Temperature is the same above and below the platen.

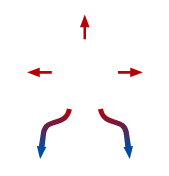

Deformation accentuating model

Upward/Downward deformation is even across the platen, so the platen stays flat.

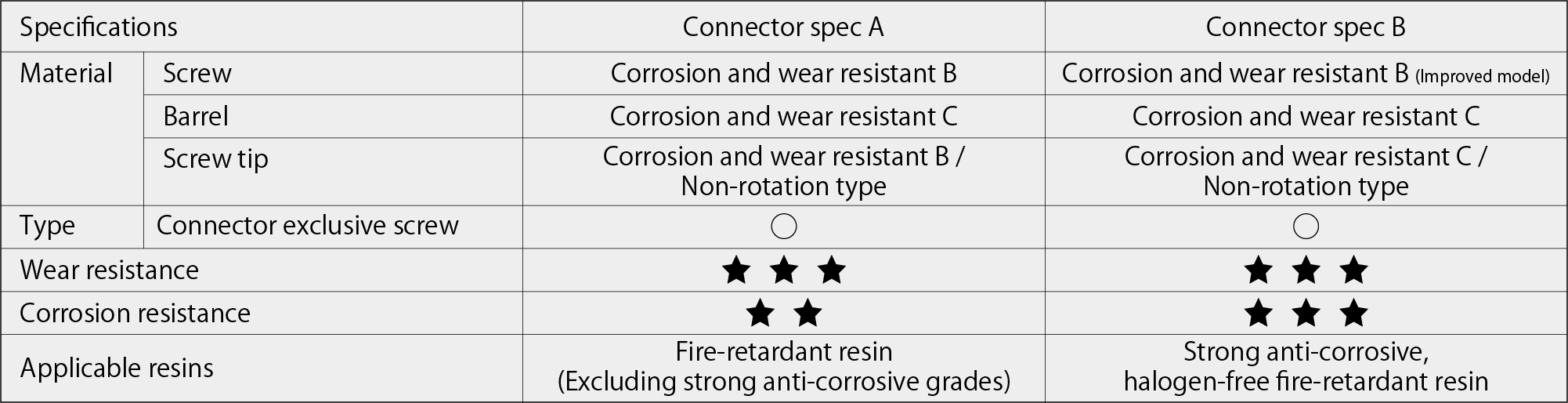

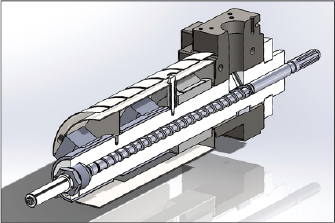

Specialized for connector molding

for connectors

The result is a yield improvement to reduce material costs.

【Comparison of resin costs】

- FTCIII nozzle

-

- Same class conventional machine

[ Resin cost ]

A stable molding process is enabled even if the regrind ratio is increased by 10%. So the use of virgin material can be reduced.

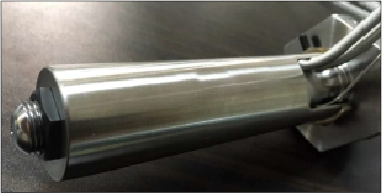

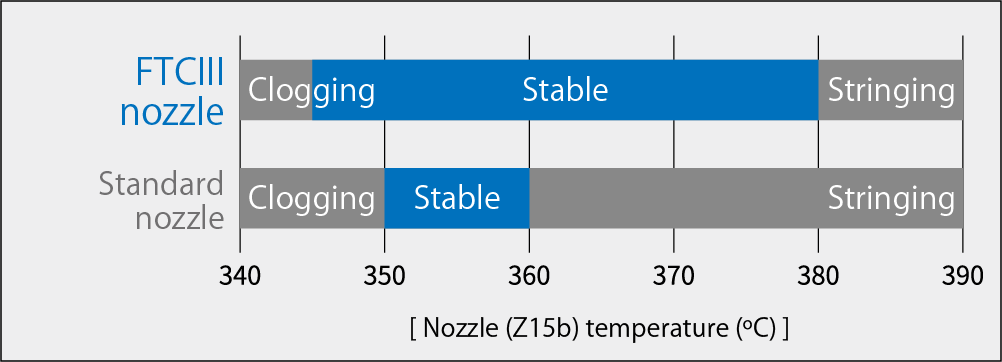

Helps to reduce costs and improve productivity

Additionally, with its long reach, it reduces the amount of sprue plastic material and shortens the mold opening stroke, which leads to a faster cycle.

Moreover, the nozzle can be detached quickly and easily, which facilitates cleaning and shortens machine down time.

【 Comparison of nozzle maintenance costs】

- FTCIII nozzle

-

- FTC nozzle (Older type)

[ Maintenance cost ]

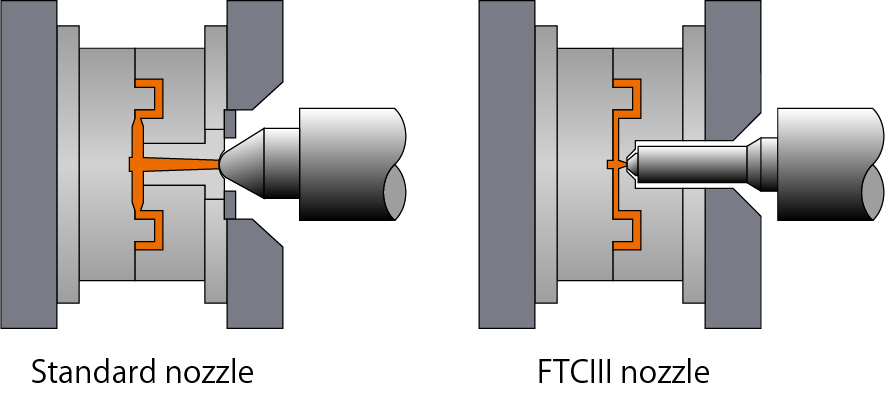

【Comparison of applicable molding conditions (LCP)】

The FTCIII nozzle provides a wider process window without causing stringing or clogging.

This eases the difficulty of setting molding conditions.