Anaerobic Wastewater Treatment and Biogas Power Generation System using Ume Seasoning Effluent bringing Recycling-Friendly Society

The Minabe-Tanabe region, located south of Wakayama Prefecture and home to more than 300 businesses producing umeboshi (pickled prunus mume, a kind of plum), is the top supplier of this traditional food in Japan. One of the long-standing issues for the local umeboshi companies is the increasing cost of properly treating the seasoning liquid effluent left after the manufacturing process as industrial waste. The wastewater contains a very high concentration of contaminants, with its biochemical oxygen demand (BOD)*1 exceeding 100,000 mg per liter, a level that conventional aerobic wastewater treatment methods*2 cannot handle easily. This means that specialist servicers who can process this effluent as industrial waste must be involved, raising the cost and undermining umeboshi manufacturers' profitability. Sumitomo Heavy Industries Environment has solved this problem with a system for anaerobic wastewater treatment and biogas power generation. The seasoning liquid effluent that had been simply discarded can now be used as biomass input for this system as an energy source, reducing both the environmental load and processing cost for the local industry.

- *1An index showing the level of riverine pollution. Environmental BOD standards for river are often set between 1.0 to 10.0 mg.

- *2A method for decomposing organic matter in water using aerobes that require oxygen for this process.

What is an Anaerobic Wastewater Treatment and Biogas Power Generation System?

One of the two ways to use biochemical methods for processing effluent is called anaerobic wastewater treatment, in which anaerobes (microorganisms that do not require oxygen) turn organic matters into methane gas, CO2, and water. In the anaerobic water treatment and biogas power generation system, a very small amount of impurities must be removed from the gas before feeding the diesel engine generators, effectively turning the effluent into energy.

Challenges for Anaerobic Processing of Umeboshi Seasoning Liquid

There had been no anaerobic wastewater treatment plant operational for processing umeboshi seasoning liquid. This is because the filamentous fungi thriving in the sugar-rice effluent create considerable difficulty for the plant's consistent operation.

Sumitomo Heavy Industries Environment has overcome this obstacle, after a long period of continuous tests, by developing and implementing technologies for controlling these fungi, to create a system that can be run consistently under high loads. The new approach can dramatically reduce the cost of processing the effluent, since it is neither as energy intensive nor generates sludge as the conventional aerobic processes do.

Towards a Recycling-Friendly Society

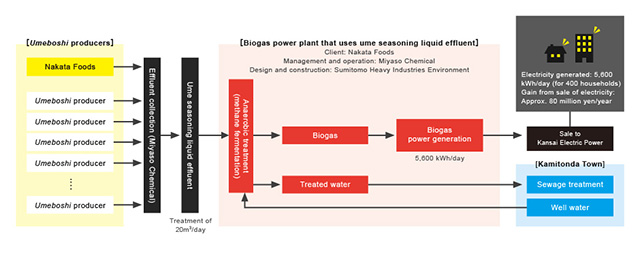

Sumitomo Heavy Industries Environment has built the new biogas power station fueled by umeboshi seasoning liquid for Nakata Foods, the leading umeboshi manufacturer. The logistics chain for this scheme was developed jointly with Miyaso Chemical, a local industrial waste treatment and transportation company, who will collect and carry the seasoning effluent from Nakata Foods and other umeboshi factories to the facility, which is also managed by Miyaso. Sumitomo Heavy Industries Environment has leveraged its historical expertise in water treatment to design and build the plant.

Furthermore, biogas generated during the anaerobic process can be turned into electricity. This energy can be sold under the feed-in-tariff (FIT) program for promoting renewable energy to cover the plant construction cost as well as giving the facility an additional revenue source to ensure its profitability. Sumitomo Heavy Industries Environment is planning to apply this approach to other types of food waste, to help us move towards a recycling-friendly society with a system that can process waste and create energy at the same time.

- *All contents are as of the time of the interview.

SHI Pride

- Vol.1 A Clear View of the Distant Heavens

- Vol.2 Cures without Surgery: Advanced Cancer Treatment

- Vol.3 Exploring the Mysteries of Space

- Vol.4 Dramatically Changing Quayside Cargo Handling

- Vol.5 Cyclo Drives Continue to Evolve

- Vol.6 The Steam Turbine - Protecting the Environment and Advancing Society

- Vol.7 Persistent Determination to Reduce Defects, Losses and Faults to Zero

- Vol.8 Treating Cancer through the Use of Neutrons - A Compact Accelerator Opens the Door to Widespread Use -

- Vol.9 Automated storage system with unrestricted movement, for transforming the future of the logistics industry

- Vol.10 Anaerobic Wastewater Treatment and Biogas Power Generation System using Ume Seasoning Effluent bringing Recycling-Friendly Society

- #01 Technology that has the potential to dramatically change automobile frame manufacturing STAF created by maintaining a comprehensive customer perspective

- #02 The ECY Series:A smaller Gear reducer after over 10 years of development

- #03 Cancer Therapy System "Boron Neutron Capture Therapy (BNCT system)"

- #04 Supporting Development with Innovative Simulation Technology: RMD and MBM

- #05 Behind the Development of the World's Highest Output Accelerator for Proton Beam Cancer Therapy - Succeeding "When It Can't Be Done."

- #06 AI-backed support system for next generation biomass power plant operations ~ Transforming the shop floor with IZANA ~