AI-backed support system for next generation biomass power plant operations

~ Transforming the shop floor with IZANA ~

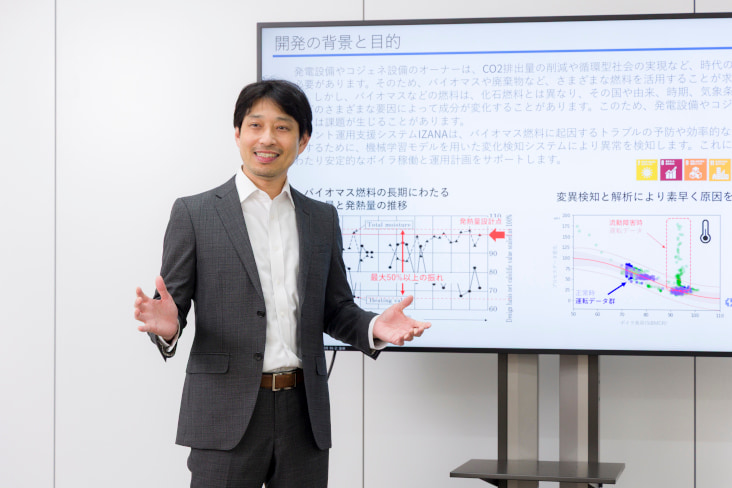

Circulating Fluidized Bed (CFB) boilers can be used to generate electricity from biofuels and are therefore attracting interest in the quest for a carbon neutral society. For stable operation it is essential to improve reliability and simplify the operator's tasks.

Researchers and engineers at Sumitomo Heavy Industries got together and used their expertise to develop IZANA*, an AI-backed system that supports the operation of such equipment.

So how did this groundbreaking system, in which AI analyzes operational data from customers' power generation facilities to ensure their stable operation, come into being?

Business Development & Promotion Dept.

Energy & Environment Group

Digital Transformation Promotion Dept.

Corporate ICT Group

Corporate Technology Management Group

Technology Research Center

Informatics and Mathematical Engineering Dept.

From superficial issues to the heart of the matter

The development of IZANA started in 2015. Colleagues were working on a way to promptly identify failures in already delivered power generation equipment when they noticed the possibility of applying a machine learning model developed by our Technology Research Center.

The name IZANA is derived from the Japanese verb "izanau," meaning "to invite," reflecting a desire to invite (izana-u) facilities, businesses, and social contribution to move in a positive direction.

When power generation facilities unexpectedly stop working, this not only causes economic damage but also disrupts electricity supplies. Customers asked us to develop systems that add to the reliability we have built as a manufacturer.

As the development of IZANA progressed, the team started to feel confident that this could become a marketable product. However, as generic technologies are normally only good for solving superficial issues, they needed to look deeper. "We went back to the shop floor over and over again to seek out the real problems and incorporated customers' feedback into the functionality," reminisces a senior engineer in the Corporate ICT Group.

Not all customers were convinced

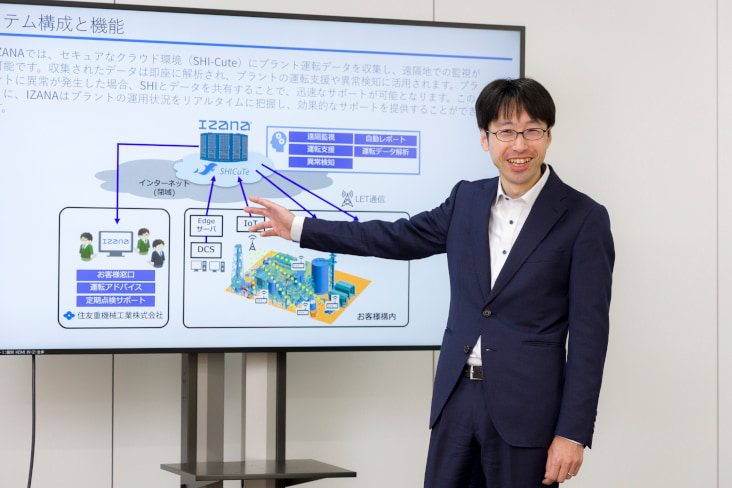

In the conventional problem solving process, staff are dispatched to the site in question where they check data and propose a plan for improvement. However, that takes a lot of time and effort.

Therefore, using the SHI Group's ICT/IoT shared platform (SHICuTe*), the team built a system that can constantly collect operational data and share it in real time while ensuring security. This enables investigators to rapidly understand the situation and propose solutions.

Trial runs of IZANA were conducted from 2018. Over a period of 3 years, a more reliable algorithm was developed, and the system was refined by carefully picking up the needs from the shop floor.

Nonetheless, that did not mean it was immediately accepted by everyone. Proud of their skilled operators, some customers were dismissive, "Our people are experts, we don't need it."

In contrast, businesses worried about technology transfer welcomed the introduction of the new system, which was given fresh impetus by the dawning of the AI era.

One senior engineer in the Energy & Environment Group describes the current status as follows. "IZANA is functional to some extent but is not yet finished. In future, we are aiming for a system that AI can run automatically even when no operators are present."

Colleagues who stepped up to keep the project on track

Our industry features very few operating support systems developed by the facility makers themselves. Most are general systems managed by IT companies.

In such a situation, it was the strong desire of the IZANA development team to "get close to the shop floor and make something really useful" that was key in driving the project to success.

Former boiler designers, factory workers and others from various backgrounds put their shop floor experience to good use and contributed to the development.

"With IZANA, tasks should become more worker-friendly, leading to a more considerate working environment," believes a senior research engineer.

IZANA was finally commercialized in summer 2023. There were many times that the project seemed to be on the verge of collapse, but colleagues stepped up each time to take the work forward.

For that reason, the project simply had to be taken through to its conclusion. For all the colleagues who offered their help, and for society that needs this technology...

*IZANA and SHICuTe are registered trademarks of Sumitomo Heavy Industries, Ltd.

SHI Pride

- Vol.1 A Clear View of the Distant Heavens

- Vol.2 Cures without Surgery: Advanced Cancer Treatment

- Vol.3 Exploring the Mysteries of Space

- Vol.4 Dramatically Changing Quayside Cargo Handling

- Vol.5 Cyclo Drives Continue to Evolve

- Vol.6 The Steam Turbine - Protecting the Environment and Advancing Society

- Vol.7 Persistent Determination to Reduce Defects, Losses and Faults to Zero

- Vol.8 Treating Cancer through the Use of Neutrons - A Compact Accelerator Opens the Door to Widespread Use -

- Vol.9 Automated storage system with unrestricted movement, for transforming the future of the logistics industry

- Vol.10 Anaerobic Wastewater Treatment and Biogas Power Generation System using Ume Seasoning Effluent bringing Recycling-Friendly Society

- #01 Technology that has the potential to dramatically change automobile frame manufacturing STAF created by maintaining a comprehensive customer perspective

- #02 The ECY Series:A smaller Gear reducer after over 10 years of development

- #03 Cancer Therapy System "Boron Neutron Capture Therapy (BNCT system)"

- #04 Supporting Development with Innovative Simulation Technology: RMD and MBM

- #05 Behind the Development of the World's Highest Output Accelerator for Proton Beam Cancer Therapy - Succeeding "When It Can't Be Done."

- #06 AI-backed support system for next generation biomass power plant operations ~ Transforming the shop floor with IZANA ~