SHI Unveils Breakthrough Technology for Eco-Friendly, Scalable Deposition of Electron Transport Layers in Perovskite Solar Cells~ Contributing to Carbon-Neutral Energy Solutions through Sustainable Innovation ~

August 18, 2025

Sumitomo Heavy Industries, Ltd. (Head Office: Shinagawa-ku, Tokyo; Representative Director, President, and CEO: Shinji Shimomura, hereinafter “SHI”) has successfully developed a breakthrough deposition technology of ultra-thin electron transport layers (ETLs). Those layers are an essential component of perovskite solar cells (*1), which are expected to power the next generation of solar energy. This innovative technology, which utilizes cost-effective materials and an environmentally friendly process, is projected to contribute to the development of cleaner and more sustainable energy solutions.

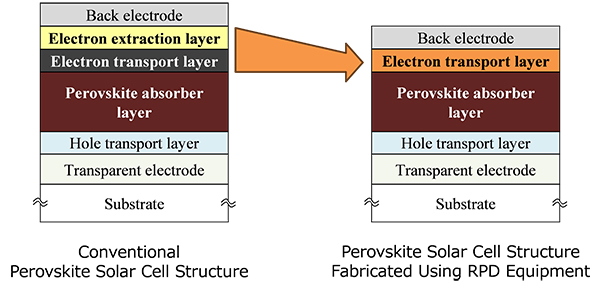

Perovskite solar cells are composed of multiple functional layers. One of which is an ETL that is deposited either above or below the electricity-generating perovskite layer. The ETL plays a critical role by enabling electrons generated in the perovskite layer to flow efficiently to the electrode. To fulfill this function, the ETL must have conduction bands capable of accepting these electrons. It is also essential that the ETL is deposited without damaging the perovskite layer, which is highly sensitive to the elevated temperature. Although they are cost-effective and suitable for mass production, conventional formation methods typically involve high energy particles and high-temperature environments. This, in turn, will make them incompatible with perovskite materials. Thus, manufacturers are actively exploring chemical film deposition methods. However, this approach faces significant challenges, such as the high material cost, the difficulty in scaling up production, and the use of toxic or flammable precursor gases.

In response to these challenges, the SHI Technology Research Center has successfully developed a new film deposition technology using its proprietary Reactive Plasma Deposition (RPD) method (*2). This method enables the deposition of tin oxide (SnO2)-based films that are suitable as ETLs in perovskite solar cells.

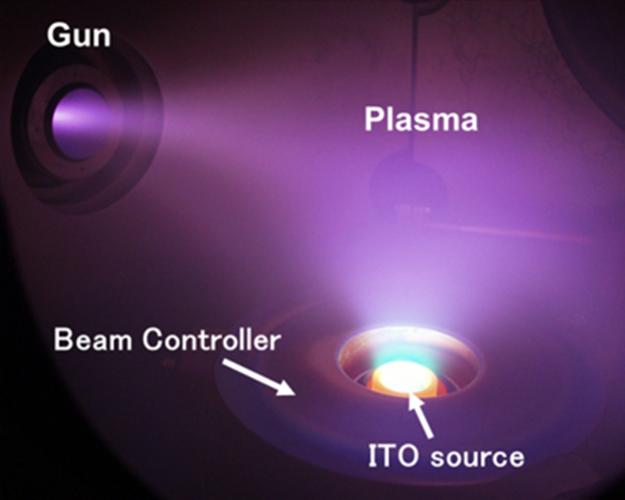

As a type of Physical Vapor Deposition (PVD), RPD is an environmentally friendly method well-suited for mass production of thin films on the top of perovskite layers. It offers several advantages, including low-temperature processing, minimal substrate damage, rapid film deposition over large area, and utilization of non-hazardous gases with minimal environmental impact. SnO2 is a low-cost metal oxide known for its excellent electrical conductivity when deposited by using PVD. However, if the conductivity is too high, it cannot function effectively as an ETL. SHI is the first in the world to demonstrate that its RPD technology can produce SnO2 films with the appropriate insulating properties required for ETLs. This breakthrough technology offers significant improvements in both mass manufacturing and cost performance, compared to the chemical film deposition methods currently under development by other manufactures (*3). Furthermore, since RPD has already been proven effective in the deposition of transparent conductive films (TCFs) from materials such as Indium Tin Oxide (ITO), which can be used in solar cells, flat panel displays, and organic EL panels, it enables a continuous process consisting of ETL deposition and TCF deposition.

By applying this film deposition technology to the mass manufacturing of perovskite solar cells, we aim to accelerate their adoption, which in turn will contribute to a carbon-neutral society.

(*1) Perovskite solar cell: A next-generation solar cell that uses a material with the perovskite crystal structure as the light-absorbing, electricity-generating layer. Perovskite solar cells offer energy conversion efficiency comparable to conventional silicon-based solar cells, while requiring significantly less energy to manufacture. They are also highly versatile, allowing for flexible designs and installation in a wide range of locations. These types of solar cells are positioned as a key technology in the Japanese government’s strategy for the next generation of solar energy.

(*2) Reactive Plasma Deposition (RPD): A highly reactive film deposition method uniquely developed by SHI. In this process, electrons supplied by a plasma gun are guided by a magnetic field toward the evaporation material, which is then heated, vaporized, and activated by the high-density plasma. RPD enables the formation of high-quality crystalline films with minimal substrate damage, owing to its highly reactive and yet gentle process.

For more details about SHI’s vacuum deposition equipment, please visit:

https://www.shi.co.jp/industrial/en/product/industry/reactive-plasma-deposition/index.html

(*3) Comparison of mass manufacturing capabilities and cost efficiency

(1) Film deposition speed

By using SHI’s new technology, SnO2 films, which are used as ETLs, can be deposited at a rate of 200 times faster than the current widely adopted method.

(2) Cost efficiency

By using SHI’s new technology, SnO2 films can be directly deposited onto the perovskite layer as ETLs. This innovative approach is expected to reduce manufacturing cost of ETLs to less than 0.5% of the one of the current widely adopted method, which involves depositing a fullerene (C60) layer on the perovskite layer, followed by chemical vapor deposition of SnO2.