Product Series of Compact Gear Motors Expands

November 05, 2013

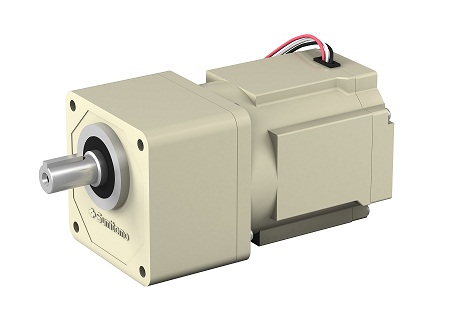

Sumitomo Heavy Industries Gearmotors Co., Ltd., (headquarters: Obu City, Aichi Prefecture; President: Tsuyoshi Okabe; wholly owned subsidiary of Sumitomo Heavy Industries, Ltd.) launched the sale of "Presto NEO", the company’s parallel axis compact gear motors that have involute gears (*), with an output up to 90W, on November 1.

Parallel axis gear motors are widely used for a variety of industrial machinery, such as compact conveyor belt drives, food processing machinery, packing machinery and farm equipment. Products that produce less noise, while offering higher reliability with easily adopted designs as well, have been in demand in recent years.

In response to such customers’ demand, SHI launched the sale of the "Presto NEO series with an output of 0.1kW to 2.2kW" in 2007, with particular attention to the "six aspects of usability". In addition, SHI launched yet another product series with an output up to 90W, in response to customers who voiced their desire for models with even smaller capacities.

* Involute gears

An involute curve (trajectory drawn by the end point of a thread when the thread, wound on a circle, is unraveled) is used for the gear profile, with a characteristic shape appearing to be like a rounded trapezoid. This gear mechanism is adopted for many products at the present time.

[Features]

1. Long life and high reliability

This super compact model has an output of only up to 90W, but features a long life with superior strength, with the same design standards as the one used for the Presto NEO series, which has a 1kW to 2.2kW output.

2. Large tolerance radial load (load acting perpendicular to the shaft axis)

A large tolerance radial load has been achieved through the adoption of a high load capacity bearing and high rigidity casing. The product line broadened the degree of freedom available to customers for their designs.

3. Output shaft end tap (screw hole)

In response to requests from customers, an M5 x 13 tap has been fitted to the end of the output shaft as a standard feature, which is unusual for gear motors of this class.

4. Low noise makes it suitable for use even in quiet environments

Quiet operations have been achieved, due to gears with a high gearing shaft ratio and highly-rigid structure, because the product is often used near humans. It has been adopted for use in products, such as welfare equipment.

5. Unified flange size

The flange size has been unified to a 90mm square screw thread for all models with a 40W, 60W and 90W output.

The diameters and lengths of the shafts are also the same, making it unnecessary for customers to work through design changes to their machinery, even if the motor capacity is changed to accommodate their use.

Furthermore, the Hyponic speed reducers, Altax gear motors and Astero gear motors all share a common flange size and can therefore be used for a variety of purposes (shaft locations and shaft circumference measurements are different).

6. Inlay processed (process intended for accurate contacts by making indentations and protrusions on joining surfaces).

Inlay process has been implemented to the casing around the output shaft in response to the wishes of customers. It is now much easier to perform centering when positioning a gear motor.

[Model makeup]

Motor output 40 60W 90W

Reduction ratio 5 7. 5 10 12. 5 15 20 25 30

40 50 60 70 (capacities all in common)

Installation method: Flange mounted, leg mounted

Motor type Three-phase 200V Three-phase 400V Single-phase 100V Single-phase 200V

With / without brakes, respectively.

[Principal applications]

Compact conveyor belt drivers, mixers, food processing machinery, packing machinery, welfare equipment, farm equipment, gaming machines

[Standard price]

JPY19,500 (in the case of a 90W three-phase motor, with no brakes and a reduction ratio of 10, tax exclusive).

[Sales target]

6,000 units per year (first year).