New Technology for Effluent Treatment Positively Impacts Energy Conservation by 75%

October 07, 2013

Sumitomo Heavy Industries, Ltd., (President: Shunsuke Betsukawa), in collaboration with the National Institute for Environmental Studies (Executive Director: Akimasa Sumi), successfully developed a technology for processing organic effluent at ambient temperatures with a methane fermentation treatment. When this technology is put into practical implementation it will be the world’s very first case example.

The effluent discharged by domestic industries in Japan amounts to approximately 11.1 billion tons and most of it is comprised of organic effluent that includes a relatively low concentration of organic matter. The majority of such effluent is currently treated using a method referred to as aerobic biotreatment (known also as the activated sludge method). Issues of this method include the consumption of large amounts of electric power and the production of excessive activated sludge in copious quantities. Such produced volumes can be significantly reduced using the methane fermentation process however the process has not been successfully popularized since the effluent for treatment has to contain a medium to high concentration of organic matter and because this method can only be applied with lukewarm liquids at medium temperatures.

The recently-developed technology can treat effluent with low concentrations of organic matter and facilitates the treatment of methane fermentation in ambient temperatures. This not only extends the range in which the method can be applied but also enables a reduction in operating energy of about 75% in comparison with the conventional activated sludge method. The development is expected to move into evaluations of the validation performance, aiming for practical implementation in the future. Practical implementation is expected to be achieved within one to two years at the earliest and this can potentially become the world’s very first case example.

Features

1) Treatment can be applied to low concentrations of organic matter in effluent and also at ambient temperatures.

Conventional methane fermentation treatment can only be applied to effluent containing organic matter at concentrations of 2 to 20 grams CODCr/L and only at temperatures between 35 and 37°C. The recently developed technology can be applied to effluent containing organic matter at concentrations of about 0.3 to 1 g CODCr/L and also at ambient temperatures (10 to 25°C). Most effluent corresponds to these conditions.

2) Energy conservation

The activated sludge method, which is currently the mainstream treatment, requires a large amount of energy for aeration operations (supplying oxygen in water to activate microbes) and excess activated sludge treatment. Aeration is not required with the methane fermentation treatment and smaller amounts of excess activated sludge are produced, therefore the operating energy in our experiment was reduced by about 75%. Furthermore, it is also possible to dramatically reduce expenses for treating excess activated sludge.

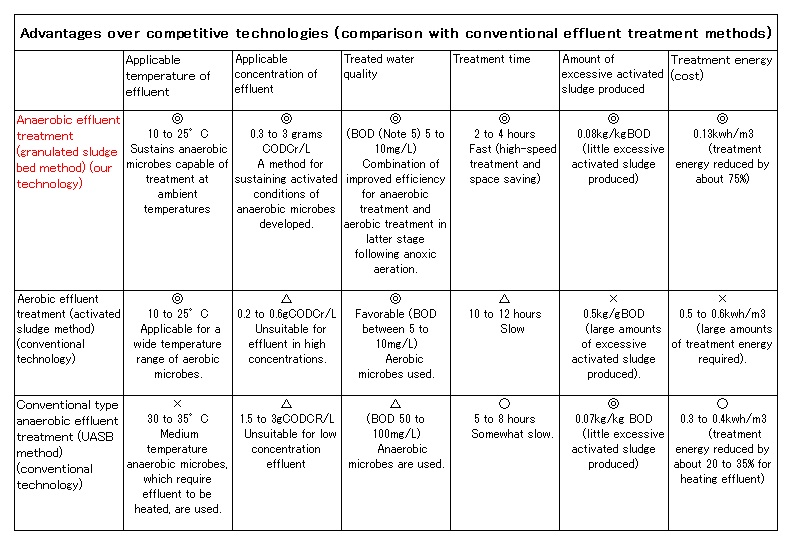

3) Comparison with conventional effluent treatment methods

COD: An abbreviation for chemical oxygen demand. The value represents the amount of oxygen consumed when organic matter in water is oxydized by an oxidant. This value is used to represent the level of contamination in an aquatic environment and also used as an effluent standard or environmental standard. Among such values, CODCr involves a method that uses potassium chromate (K2Cr2O7) as an oxydizing agent, as well as a method that uses permanganic acid potassium salt (KMnO).