Sumitomo Heavy Industries Process Equipment Introduces a Pilot Plant for Plastic Recycling of Automotive Parts at Honda R&D

October 06, 2025

Sumitomo Heavy Industries Process Equipment Co., Ltd. (Head Office: Shinagawa-ku, Tokyo; President: Shigeru Tajima; a wholly-owned subsidiary of Sumitomo Heavy Industries, Ltd.; "Sumitomo Heavy Industries Process Equipment") has developed a pilot plant for plastic recycling ("Facility") together with Honda R&D Co., Ltd. (Head Office: Wako-shi, Saitama; President and Representative Director: Keiji Otsu; "Honda").

Honda is tackling the recycling of plastic waste recovered from end-of-life automobiles. To this end, it developed "chemical sorting” technology that contributes to the recycling of plastics ("Technology"*1). Going forward, Honda intends to perform a verification of the Technology at the pilot plant.

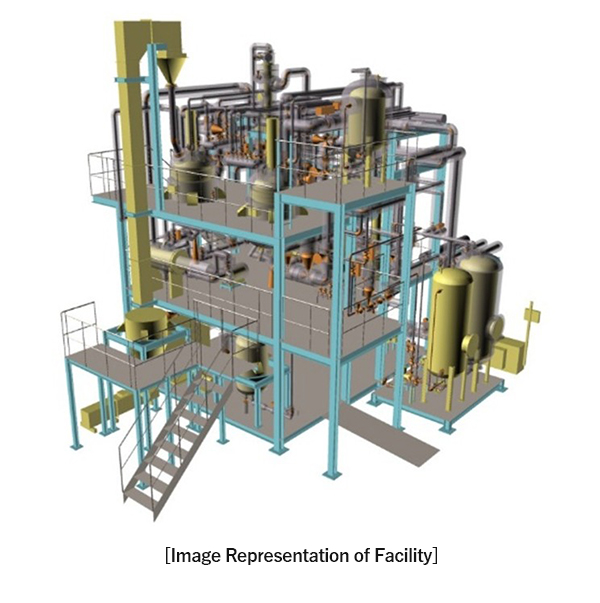

Using basic concept of specification by HONDA as the foundation, Sumitomo Heavy Industries Process Equipment fused together its core technologies and plant engineering prowess as a mixing system manufacturer to develop facility specifications and the plant's composition alongside Honda while closely affiliating with the company from the initial planning stages, including the examination of equipment. In doing so, Sumitomo Heavy Industries Process Equipment successfully scaled up the Technology to the pilot stage.

By employing a modular construction in which the entire plant is temporarily assembled once at the production factory, then transported to the site in block units for installation, the Facility realizes benefits such as shorter construction periods and more compact plants. Additionally, the mixing system in the Facility contains core technologies by Sumitomo Heavy Industries Process Equipment, including MAXBLEND*2.

Sumitomo Heavy Industries Process Equipment will continue to provide customized plant facilities closely aligned with the needs of its customers by leveraging its proposition capability and engineering prowess in order to continue contributing to the realization of a circular economy.

*1: As plastic waste originating from end-of-life automobiles contains metals, glass fibers and other solid foreign objects, improving its recycling rates and reducing associated costs are currently considered challenges. Plastics, the target of the Facility, were originally disposed of through incineration. The Technology has made it possible to extract high-purity plastics with over 99% of solid foreign objects removed. The high-purity plastics extracted using the Technology can be reused as materials for automobiles after they have gone through a recycling process.

*2: For details on MAXBLEND, please refer to the below.

https://www.shi-pe.shi.co.jp/english/products/mixing/maxblendclub/mbabout.html