Column-In-Column has been selected under “advanced equipment and systems” as part of the Energy-Saving Investment Promotion and Demand Structure Transformation Support Project in the fiscal year 2024 supplementary budget.

September 17, 2025

Column-In-Column next-generation distillation system developed by Sumitomo Heavy Industries Process Equipment Co., Ltd. (“Sumitomo Heavy Industries Process Equipment”) (Head Office: Shinagawa-ku, Tokyo; President: Shigeru Tajima; 100% investment by Sumitomo Heavy Industries, Ltd.) displays excellent energy-saving and space-saving performance. The system has been selected to receive an equipment subsidy under the “2024 Energy-Saving Investment Promotion & Demand Structure Transformation Support Project” supplementary budget, which is a subsidy project operated by the Sustainable open Innovation Initiative (“the Project”).

The Project offers subsidies for advanced equipment with high technical capabilities and energy-saving performance. Equipment is selected based on screening criteria determined by the Agency for Natural Resources and Energy, at the Ministry of Economy, Trade and Industry.

■ Features of Column-In-Column

Column-In-Column system excels in energy efficiency and space-saving. It is a next-generation distillation column that operates with energy savings and reduces CO2 emissions compared to conventional multi-column systems in distillation processes for the chemical industry, which is known for its high CO2 emissions.

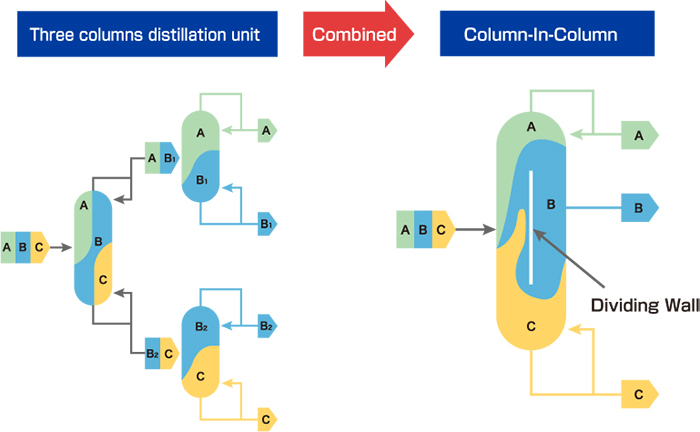

Typical multi-component distillation systems achieve separation by connecting multiple distillation columns. This involves repeated heating and cooling in each column, leading to high consumption of utilities such as steam, heat media, and cooling water, resulting in high running costs. In contrast, Column-In-Column system integrates the functions of multiple distillation columns into a single column by installing vertical divided wall inside the column. This contributes to reduced use of utilities, including steam, heat media, and cooling water.

Sumitomo Heavy Industries Process Equipment has delivered approximately 50 systems, both in Japan and internationally, helping to realize up to approximately 40% reductions in energy consumption and CO2 emissions. Looking ahead, Sumitomo Heavy Industries Process Equipment will continue making active efforts to develop and promote energy-saving technologies in order to reduce negative environmental impacts and contribute to the realization of a sustainable society.

- Further details about Column-In-Column are available here:

https://www.shi-pe.shi.co.jp/english/products/jyouryu/cic/

- For inquiries and advice about this topic, please contact us here:

https://page.shi-pe.shi.co.jp/distillation_contact_eg.html

(Ref.) Further details of the Project are available here (in Japanese).

- Sustainable open Innovation Initiative

https://sii.or.jp/

- Energy-Saving Investment Promotion & Demand Structure Transformation Support Project subsidies

https://syouenehojyokin.sii.or.jp/124business/

- Published outline of “advanced equipment and systems” in the “Factories and workplaces” category

https://sii.or.jp/file/koujou_system_search_06r/R6Hsen-519.pdf