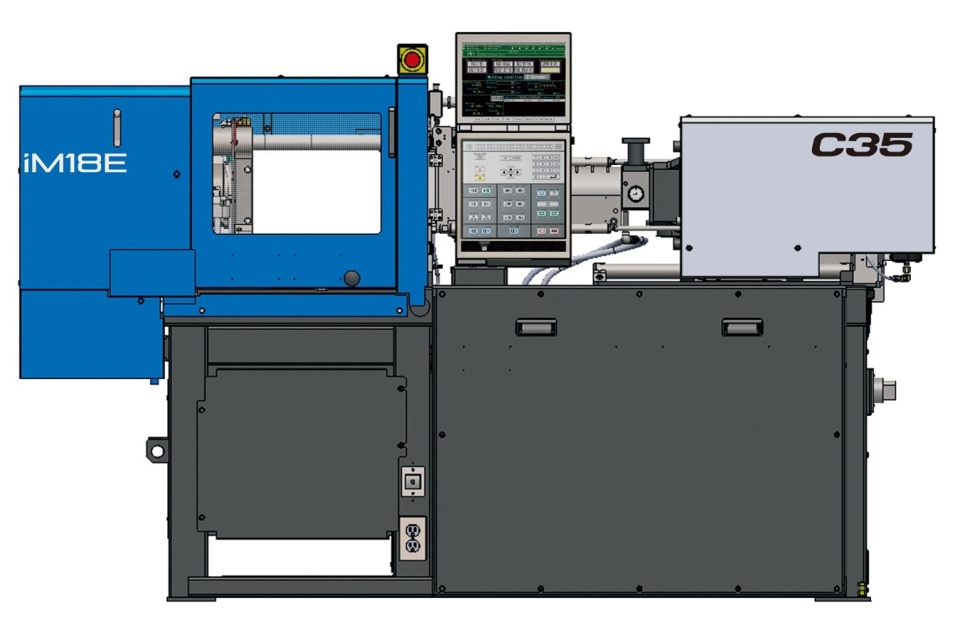

SHI begins sales of the iM18E, a small-size hybrid injection molding machine designed for space savings and quality

January 31, 2023

Sumitomo Heavy Industries, Ltd. (Head Office: Shinagawa-ku, Tokyo; Representative Director, President, and CEO: Shinji Shimomura) will launch the iM18E, a small-size hybrid injection molding machine with the smallest footprint in the 18-ton class machines and high precision stability, on January 31, 2023.

This new product is designed especially for molding connectors, precision gears, and other electronic parts, the demand of those has been increasing in recent years.

SHI will continue to provide first-class products and services to the world.

*Image is for illustrative purposes only

■ Main specifications

| Maximum clamping force | 180kN |

|---|---|

| Clamping method | Direct pressure |

| Maximum injection speed | 600mm/s |

| Footprint (L x W) | 2242×759 |

■ Main characteristics of the product

1) Space-saving production lines

The iM18E occupies approximately 21% less space than the SHI’s equivalent model SE18DUZ. It is the smallest injection molding machine in the 18-ton class machines. The floor space necessary for iM18E is greatly reduced due to plasticizing device that does not require slewing motion and a structure that allows peripheral equipment to be housed under the machine. This makes it possible to build a production line consisting of much more molding machines.

2) A hybrid configuration optimized for small-part molding

The iM18E’s hydraulic direct-pressure clamping device applies mold clamping force to the center of the platen realizing better mold venting. The electric plasticizing unit is equipped with originally developed low-inertia servomotor. Controlled by the ISCII direct drive system, the iM18E reduces shot-to-shot weight variation to about one-third of that of equivalent hydraulic machine. It also raises up maximum injection speed up to 600 mm/s. These features allow it to realize the precision filling of small moldings with more difficult construction.

3) Reduction of power consumption

With a hybridized drive system and significantly improved energy-saving technology, the iM18E reduces power consumption to 50% in comparison with the equivalent hydraulic machines. It is a machine stepping forward in realizing sustainable society.