World’s first production system that revolutionizes the automotive body and frame Implementing STAF (Steel Tube Air Forming) equipment

May 18, 2022

Sumitomo Heavy Industries, Ltd. (Head office: Osaki, Shinagawa, Tokyo; President and CEO: Shinji Shimomura) would like to announce that it has decided to implement the world’s first automotive body and frame production system (STAF), which it has been developing, at Topia Co., Ltd. (Head office: Suzuka City, Mie Prefecture, President and CEO: Hideki Sasaki).

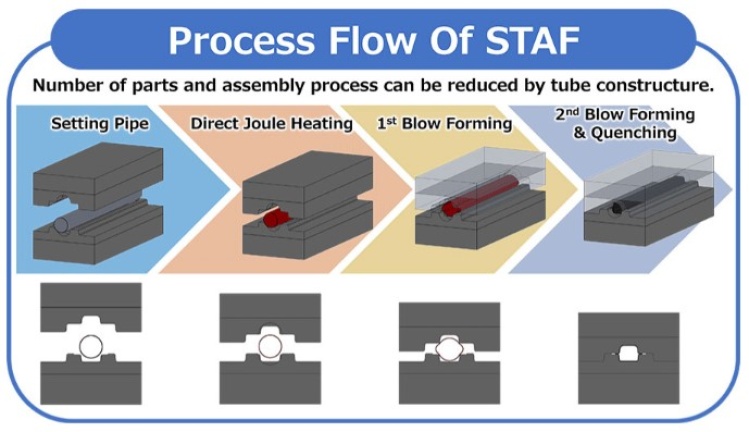

STAF is a system in which steel tubes are set in the mold on a press machine and then formed using the processing sequence of electrical heating, high-pressure air injection, molding and then hardening. This system has the advantage of being able to form flanges (components with a projecting rim) and frames together as one piece, flanges being a vital component during frame assembly. This can improve frame rigidity and simplify the production process because there is no need to weld the flange to the frame later on, as is the case with conventional methods. Moreover, increasing frame rigidity enables thinner material to be used, which has the effect of reducing the weight by approximately 30% in comparison to conventional structures.

Topia Co., Ltd. is a company that leads the way in developing and producing prototype components that are essential to the development of new products for automobiles and similar products. Implementing the STAF production system will enable Topia to provide molded components that can respond to the needs of the automotive industry, which further seeks to make vehicles more lightweight.

SHI will continue to strengthen its proposals for producing mass production components using the STAF production system and provide them to the automotive industry in both Japan and overseas through the implementation of this equipment. We will also be exhibiting this equipment at the Automotive Engineering Exposition 2022 scheduled to be held in Yokohama from May 25, 2022.

[Overview of STAF (Steel Tube Air Forming)]

1. Electrical heating

Both ends of the material pipe are clamped by electrodes and then electrically heated in the mold to rapidly heat the material.

Compared to furnace heating, electrical heating is extremely energy efficient and can significantly reduce running costs and environmental impact.

2. Primary blow (flange forming)

After heating the material pipe, the mold is closed to a half-open state using proprietary control technology and high pressure air is blown from inside the pipe to mold the flanged section.

3. Secondary blow (main unit molding) & material hardening

After closing the mold, high pressure air is blown to further shape the main unit section to the inner surface of the mold, and to perform blow molding. As the material adheres to the mold, it rapidly cools to produce a 1500 MPa grade high-strength member.

[Overview of implementing the equipment]

Location of implementation: Topia Co., Ltd. Suzuka headquarters plant

Overview: Improvement of the existing 1500 ton general purpose hydraulic press machine

Applications: Automotive body parts (A pillars, bumper reinforcement, door beams, etc.)

Operation: Scheduled for August 2022