The MBS Screw is a barrier screw developed in-house for low heat generation and high output rate.

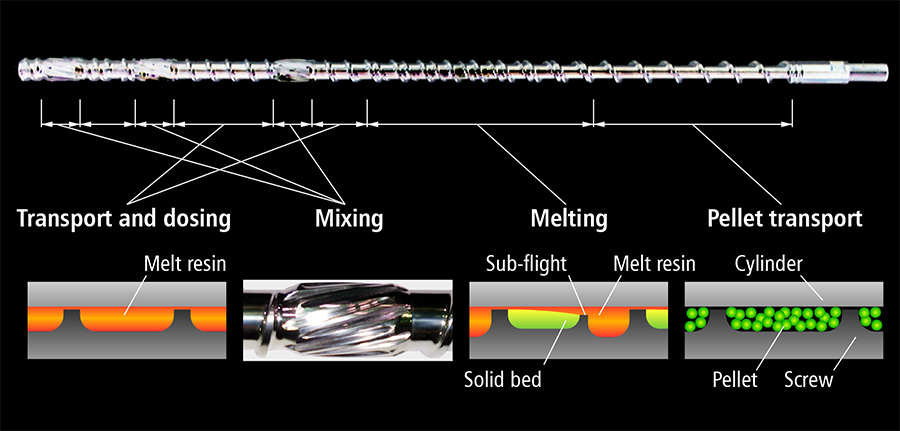

Resin deterioration caused by oxidation is prevented in the melt channel of the barrier inlet by slightly pressurizing the inlet so as to promote melting.

The barrier’s sub-flight is connected to the main flight, and, by completely separating the solid zone from the melt zone, unmelted resin does not flow into the metering zone.

With barrier screws of other manufacturers, the sub-flight is open on both ends (barrier inlet and outlet) in order to increase output rate,

but this kind of configuration defeats efforts to guard against incomplete melting and bubbling.

Moreover, the cross-sectional area is changed by adjusting the flight lead and thread depth, effectively eliminating sudden cross-sectional deformation and impeding resin pooling and extrusion fluctuations.

Our B-Mixer (Barrier Mixer) with its high rolling and chaos effects can be mounted on the barrier outlet and screw tip to further enhance kneading and output rate.

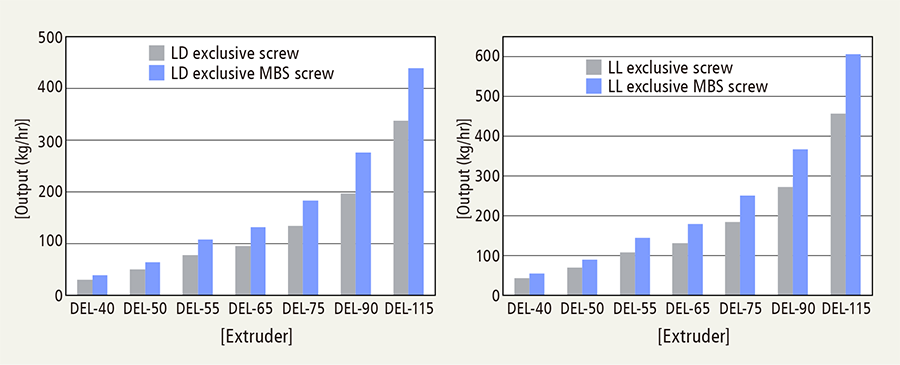

▌ High Output Rates with Low Heat Generation

Because the barrier prevents the passage of unmelted resin and enhances kneading via rolling and chaos effects, the extrusion rate per screw turn increases even at low resin temperatures.

▌ Minimized Fluctuations in Output Rate and Pressure

Fluctuations in extrusion rate and pressure are minimized because only melted resin flows to the sub-flight side and unmelted resin is kept from flowing to the metering zone in the solid bed.

▌ Reduced Dispensing of Unmelted Granules

Because the barrier prevents unmelted resin from passing, the resin in the metering zone is almost completely melted. As a result, less unmelted granules are dispensed.

▌ Bubbling Prevention Effect

Pressure is generated if resin passes over the barrier, forcing any air in the melted resin back to the feed side and effectively preventing the intrusion of air bubbles on the sub flight side. This is highly effective with resins that generate bubbles such as PS, PA, PET and EVOH.

▌ Energy-saving Effect

Owing to the deep threads in the screw, shearing stress is minimized, thus placing less load on the motor and reducing energy consumption.