This line forms films by blowing air to elongate resins extruded from a ring die. It can make protective film, masking film, agricultural film, heavy-duty bags, infusion bags and more. Various models are available to meet application purposes.

| Type | Co-OI | Co-RI | Co-RT | Co-RD | Co-MP | Co-DI |

| Costs | ★★ | ★ | ★ | ★★ | ★★★ | ★★ |

| Space-saving | ★★ | ★ | ★ | ★★ | ★★★ | ★★★ |

| Maintenance | ★★ | ★★ | ★ | ★★ | ★★★ | ★★ |

| Operability | ★★ | ★★ | ★★ | ★★ | ★★★ | ★★★ |

| Shape of Film Roll | ★★★ | ★★★ | ★★ | ★★ | ★ | ★★ |

| Resin Path Length | ★★★ | ★★★ | ★★★ | ★ | ★★★ | ★★★ |

★★★ Very Good ★★ Good ★ Fair

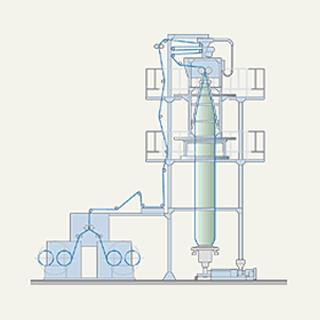

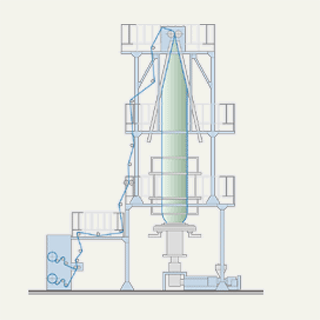

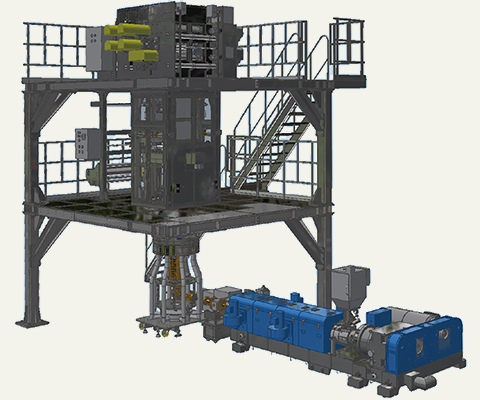

▌ Type Co-OI (Take-up unit oscillating type)

The take-up unit turns around to produce high quality film of a better finished roll shape.

Target products: Base films for lamination, barrier films, protective films

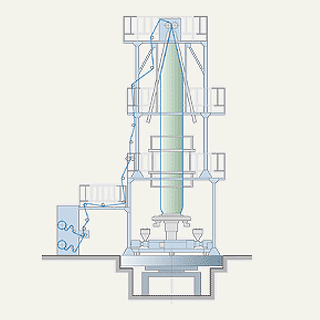

▌ Type Co-RI (Take-up unit and winder rotating type)

The take-up unit and winder rotate simultaneously to completely shut out environmental effects such as surrounding temperature, and produce high quality film with good uniformity.

Target products: Protective films

▌ Type Co-RT (Extruder rotating type)

This type offers the merit that ambient temperature inconsistencies caused by the extruder are dispersed by rotating the extruder.

And, the take-up unit is of a simple configuration that readily lends itself to line expansion.

Target products: Agricultural films, shrink films

▌ Type Co-RD (Die rotating type)

The rotating die helps to reduce costs and enhance ease-of-use.

Target products: Standard bags, agricultural films

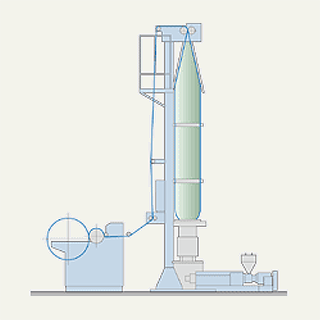

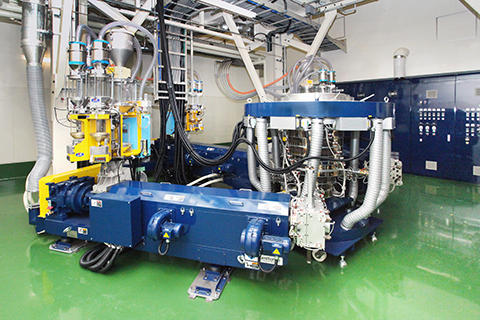

▌ Type Co-MP (General purpose type)

This general-purpose line is space-saving, low cost and easy to operate and maintain.

Target products: Standard bags, shopping bags

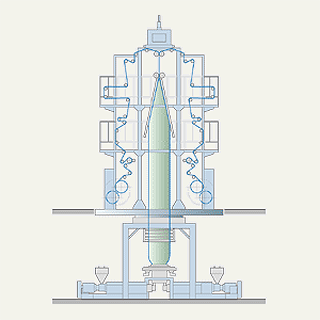

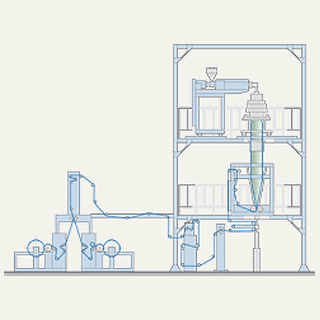

▌ Type Co-DI (Downward type)

This Co-DI forming line is designed for downward delivery best-suited for low melt viscosity resins like PP, PA, EVOH, etc.

Target products: Infusion bags, protective films

▌ Base Films for Lamination

These systems form the base films used for lamination. Precision thickness control ensures a smooth transition to secondary processing.

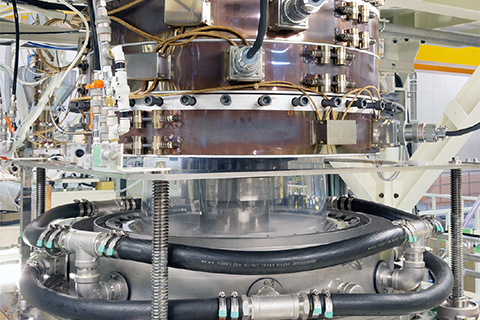

▌ Films for Infusion Bag

These water-cooled Co-DI type systems form films for transfusion bags by downward blowing. The stabilizer and take-up rotate in sync to ensure neatly formed rolls. We can propose entire production environments for manufacturing transfusion bags, including clean rooms.

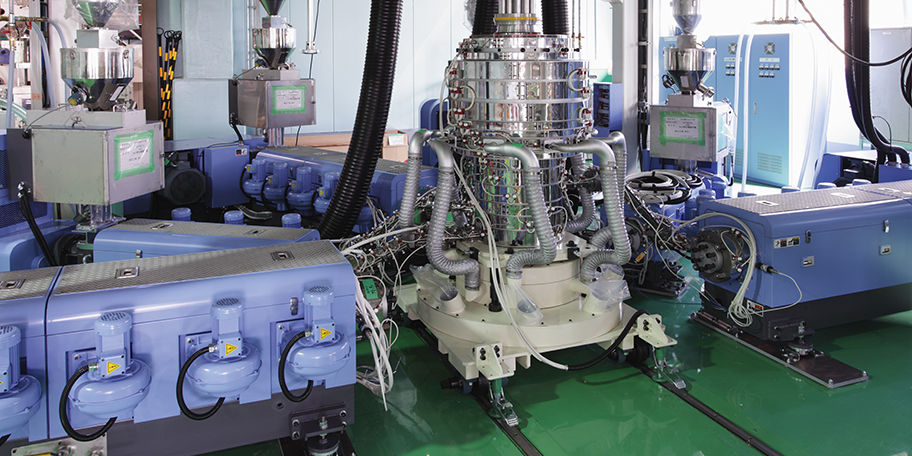

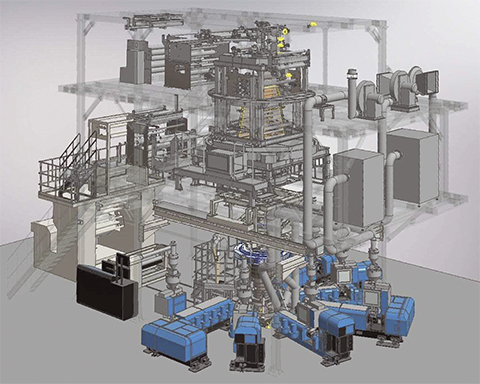

▌ Multi-layered Films

These systems form multi-layer films with barrier property, strength and other desirable properties. They can form films of up to a maximum of 9 layers, opening the doors to advanced product development and production.

▌ Stretched Films

These systems feature a special primary cooling mechanism and simultaneous biaxially stretched that ensures well-balanced orientated films.

▌ Engineering Plastic Films

Built with featured mechanisms developed from years of experience and know-how, these systems stably produce films from engineering plastics like LCP.