PRODUCTS & SERVICES

Vacuum Deposition Devices

The reactive plasma deposition (RPD) method, a unique technology of Sumitomo Heavy Industries, has been applied to vacuum deposition equipment used in the production of solar cells and LEDs, and is being applied to surface treatment equipment by generating and irradiating negative atomic oxygen (O-) ions.

Sumitomo Heavy Industries’ vacuum deposition and surface treatment technology using the RPD method

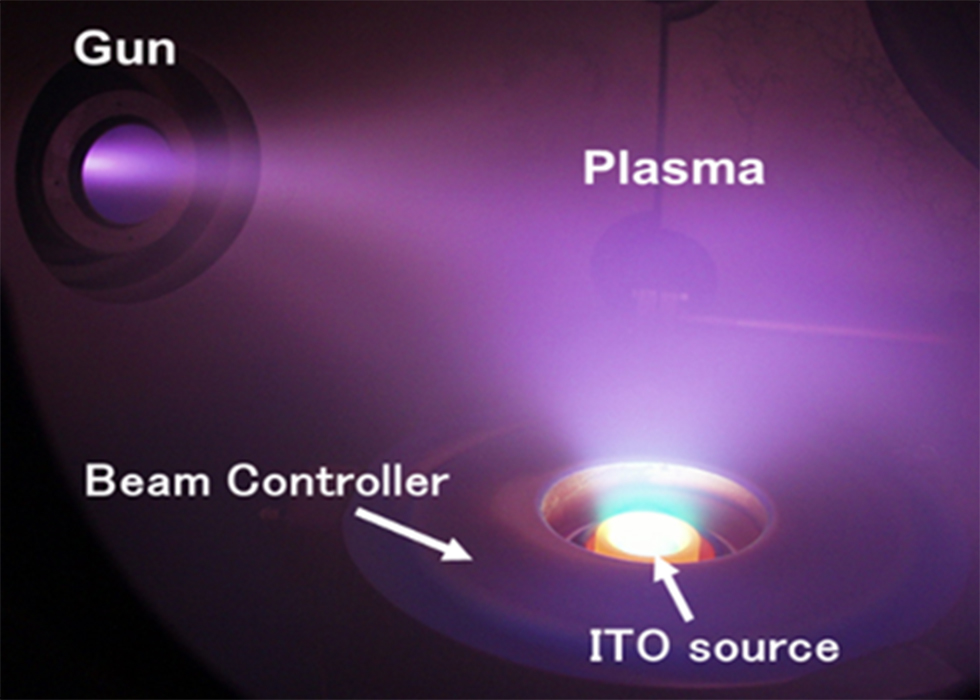

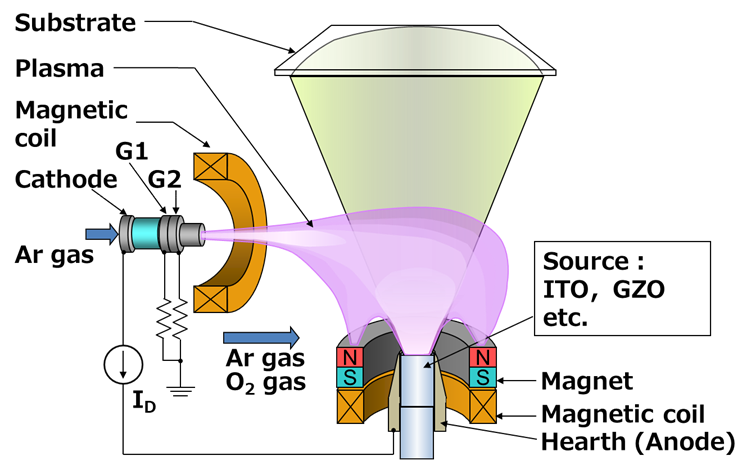

Overview of the RPD method

The Reactive Plasma Deposition (RPD) method is one of the ion-plating methods. The evaporation source, which is the anode, is heated and evaporated by the electron beam via the magnetic field-controlled high-density plasma supplied from the pressure-slope type plasma gun. The evaporated particles are dissociated, activated and ionized in the high density plasma, so high reactivity can be achieved during film deposition. We can control the evaporation distribution and achieve arbitrary film thickness distribution using our unique plasma beam controller. The incident energy of the flying particles onto the substrate can be controlled between 3¬–70 eV, resulting in low damage to the substrate. Thus, we can form microcrystalline free amorphous films and excellent crystalline films by controlling the reactivity and the incident energy of flying particles onto the substrate.

In recent years, we have applied this technology not only to vacuum deposition but also to surface treatment technology. We have been investigating a control of defects in transparent conductive oxide (TCO) films, a surface modification, and an oxidation treatment of various substrates by generating and irradiating high-density negative atomic oxygen (O-) ions using our unique after-arc plasma method.

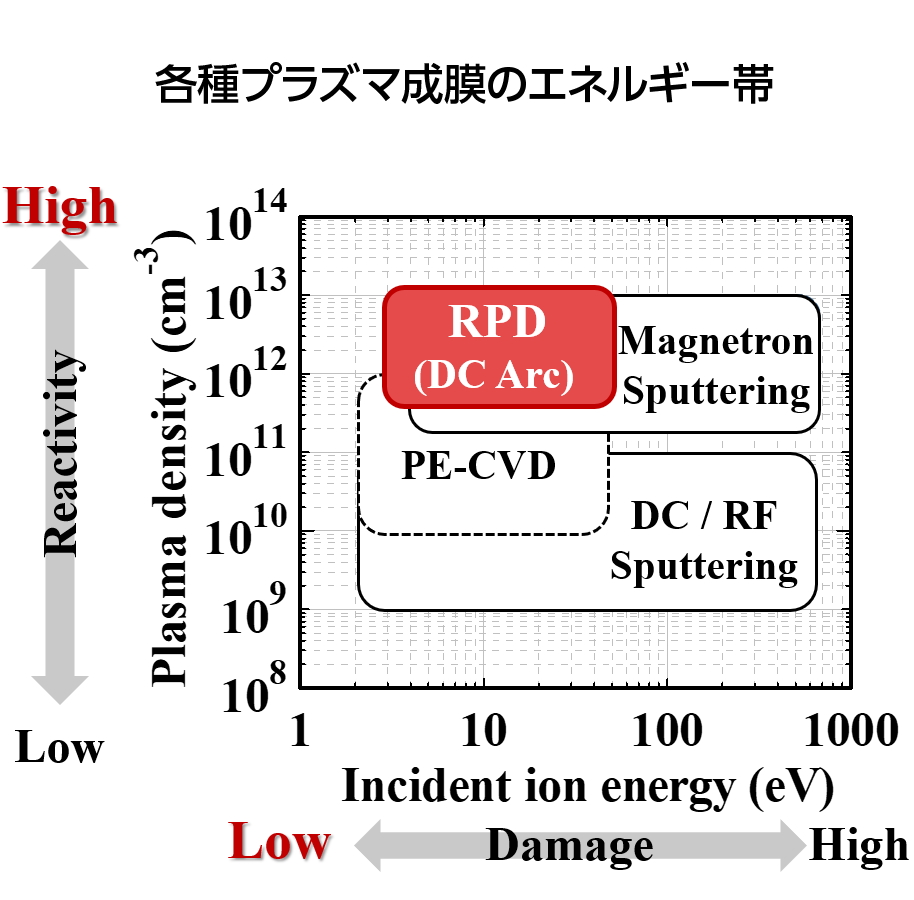

Advantages of the RPD method in plasma deposition

The RPD method is an ion-plating method with low-voltage and high-current arc discharge. The plasma gun, the cathode, and the evaporation source, the anode, are connected by a magnetic field-controlled high-density plasma. Therefore, the evaporated particles are immediately dissociated, activated and ionized, and the positive ions are accelerated by the potential near the anode and the space charge potential of plasma to fly to the substrate. The ratio of positive ion flux to the sum of positive ion flux and neutral flux of the incident particles to the substrate is more than 90% for metallic elements such as indium and zinc. The incident energy of ions to the substrate can be controlled in the range of 3–70 eV, so that the energy can be optimized according to the material to be deposited. The plasma density is 1011–1013 cm-3, thus high reactivity can be expected.

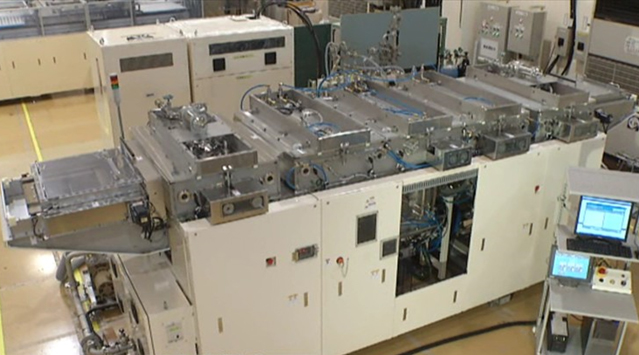

We mainly produce vacuum deposition equipment for TCO films such as ITO, Ga doped zinc oxide (GZO) and encapsulation films such as silicon oxynitride (SiON). The main application areas are solar cells, flat panel displays, organic EL, etc.

Sumitomo Heavy Industries’ RPD deposition equipment has the following advantages:

·Low electrical resistivity of TCO films

·Low damage to the substrate

·Low surface roughness

·Continuous operation for a long time

·High discharge stability

·High adhesion

·High deposition rate.

In the case of TCO films, the RPD equipment enable us with growth high-quality film compared to other methods, our method contributes to improving the conversion efficiency of hybrid solar cell, which is high efficient in crystalline solar cells, as well as the luminous efficiency of lighting using LEDs and organic ELs.

We are able to provide a wide range of services from test or pilot apparatus to mass production equipment using RPD technology, which has these features, and we will make a proposal to meet your needs.

Negative atomic oxygen (O-) ion irradiation technology

Sumitomo Heavy Industries and Kochi University of Technology have succeeded in generating a high concentration negative atomic oxygen (O-) ions by applying the RPD method through joint research. We are developing this technology to irradiate this O- ions to semiconductor films and other objects with the aim of industrial applications.

Examples of O- ions irradiation

(1) Effects on GZO film structure: control in oxygen vacancy concentration of film

(2) Improvement of hydrogen sensor performance using ZnO films

(3) Carrier concentration control of ITO films

(4) Oxidation treatment of copper plates

Negative ionization is possible as long as the element has a high electron affinity. We are aiming to apply to various industries by generating and irradiating not only the O- ions but also negative ions of various elements.