MCM (Minimum Clamping Molding)

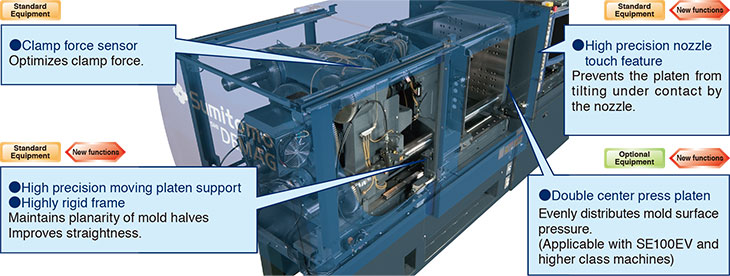

Evolved MCM via a high precision clamping mechanism

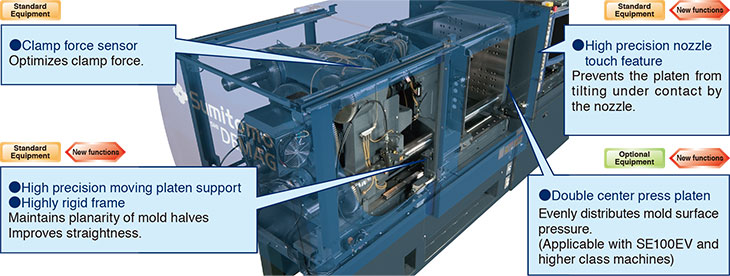

The SE-EV Series incorporates a linear guide support for the moving platen, a highly rigid frame and a high precision nozzle touch feature. Together, they improve precision at low clamp force in the form of clamping accuracy, clamp force balance, planarity and surface pressure. As a result, molding is stable even at extremely low clamp force.

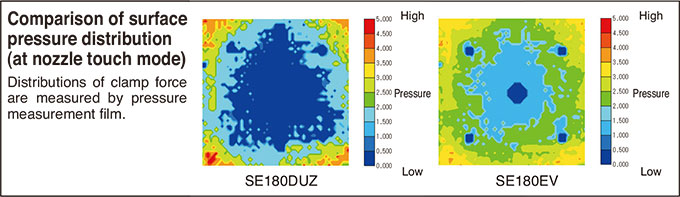

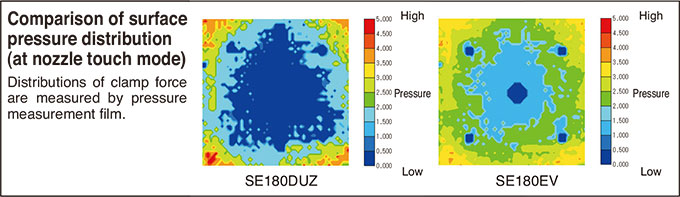

Good surface pressure balance at low clamp force

With earlier machines, more than the necessary clamp force was needed to balance the surface pressure applied to the mold. The SE-EV Series incorporates a new feature that balances this surface pressure even at low clamp force.

Clamp force feedback

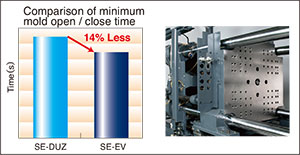

Low vibrations in high cycle molding