Successful Production of FT Synthetic Fuels Using a SBCR

November 29, 2023

Sumitomo Heavy Industries, Ltd. (SHI; Head Office: Shinagawa-ku, Tokyo; President and CEO: Shinji Shimomura; hereinafter “SHI”) has successfully conducted fuel synthesis with SHI’s own Fischer-Tropsch (FT) catalyst (FT synthesis*1) using a slurry bubble column reactor (SBCR). Taking the results of this research and the "Successful Production of FT Synthetic Fuel from Synthesis Gas with an Admixture of 20% Carbon Dioxide" announced on October 19, 2023, we will continue to study the practical application of FT synthetic fuels to contribute to a more decarbonized society.

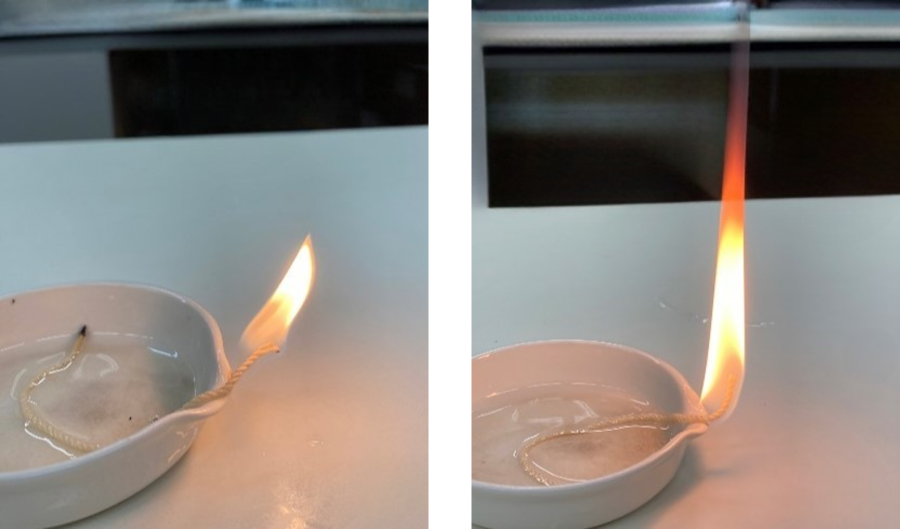

In this undertaking, we succeeded in synthesizing fuels comparable to jet fuel and diesel fuel from synthesis gas (syngas) by using a SBCR to bring synthesis gas into contact with a SHI-developed catalyst. An SBCR vents synthesis gas into a liquid-state product oil to disperse the catalyst. It therefore has excellent FT reaction heat removal characteristics and the ability to maintain a constant reaction temperature, qualities that facilitate the promotion of chain growth.

In this research project, we verified FT synthesis in the SBCR as a step toward its practical use. Looking ahead, we will study ways of optimizing the catalyst and examine the practical application of technologies for producing FT synthetic fuels from synthesis-gases containing CO2 in the SBCR.

FT synthesis is a reaction that synthesizes liquid fuel (liquid hydrocarbons) from a synthesis gas comprising carbon monoxide (CO) and hydrogen (H2). Looking to achieve the effective utilization of CO2, we aim to produce synthetic fuels such as kerosene, sustainable aviation fuel (SAF), and diesel by using CO2 and hydrogen as raw materials and applying a two-stage synthetic fuel process consisting of a reverse water gas shift reactor (reactor for producing carbon monoxide [CO] from CO2) and an FT reactor. FT synthetic fuels with high paraffin content are resistant to denaturation. They are also sulfur-free and aroma-free and less likely to produce SOX and soot in their exhaust gases.

In addition, existing internal combustion engines and fuel infrastructure can use FT synthetic fuels without modification. Consequently, end-users do not need to invest in additional equipment, which minimizes the introduction costs for decarbonization measures.

We are proceeding with development aimed at achieving fuel synthesis using synthesized gas generated by SHI’s gasifiers or so-called “green CO2” recovered from SHI’s biomass power plants and hydrogen as raw materials.

This development is being carried out with the cooperation of the Gunma Prefectural Industrial Technology Center.

*1: FT (Fischer Tropsch) synthesis is a reaction that synthesizes liquid fuels (liquid hydrocarbons) from synthesis gas made of carbon monoxide (CO) and hydrogen (H2). The technology was established by Franz Fischer and Hans Tropsch in the 1920s. There are high expectations that the process using CO2 as a raw material will be a promising technology for “carbon recycling”, together with methane, methanol, DME synthesis, and the like.

■ Related press release

October 19, 2023: Successful Production of FT Synthetic Fuel from Synthesis Gas with an Admixture of 20% Carbon Dioxide