This application improves productivity by reducing setup time with automatic mold changing process. You can avoid human error and achieve greater operating efficiency.

Issues

- Mold damage due to wrong molding conditions

- Scrap of molded products due to wrong mold

- Waste of setup time due to misoperation of crane

- Loss of production time due to improper tightening of mold bolts

Solutions

Peripheral units (Air/hydraulic/magnetic clamps, auto coupler, mold changer) are connected to a molding machine and automatically controlled by commands from the molding machine.

Example benefits

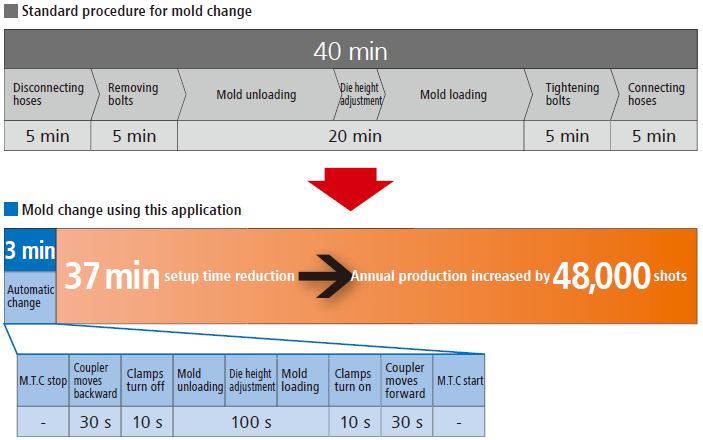

We compared the setup time of mold change process with this application to the standard procedure.

This application saves 93% of setup time, which will greatly increases annual production.

■Standard procedure for mold change

40 min

↓

■Mold change using this application

Automatic change : 3 min

- Setup time reduction : 37 min

- Annual production : increased by 48,000shots

Technical Specification

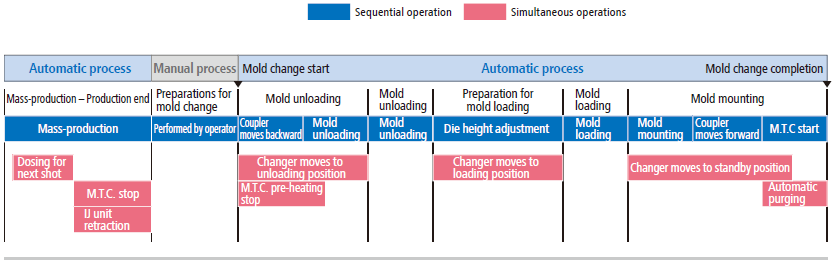

Operation Flowchart

Interface Specifications

| Clamping unit |

I/O (Built-in type, operating switch installed on a molding machine) |

| Auto coupler |

I/O (Operating switch installed on a molding machine) |

| Mold changer |

CC-Link IE Field (Molding machine: Slave / Changer: Master) |

Available models

SE75EV-S~SE180EV-S / SE-EV-S-HD

SE75EV-A~SE180EV-A / SE-EV-A-HD