IMM has Input/Output signals for injection, mold open/close, ejection, core pull to communicate with peripheral equipment.

Issues

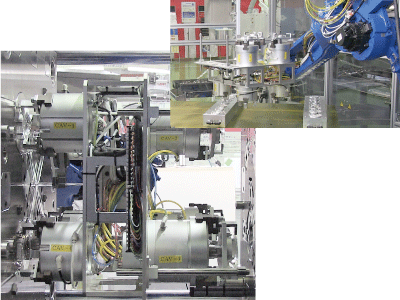

When molding with an insert + using core pull

The core works after the robot places the insert in the mold. If the inserts are not placed properly, could the core pins be damaged?

When performing vacuum molding

The vacuum pump works at mold closing pause. Mold closing restarts after a certain period of time, and injection performed when the mold fully closed. In this process, is it ever difficult to know whether the vacuum level has reached the predetermined value or not?

Solutions

Insert molding+Core pull

When the insert is placed at proper position, the robot provides "core in permitted" signal to IMM.

This prevents mold damage by insert problem.

Vacuum Molding

IMM locks up the mold after vacuum gage provides confirmation signal to IMM.

So you can reduce bad products by desired vacuum level.

Example benefits

When IMM runs with robot or other devices, proper interlock signals provides followings.

Safety and flexibility for equipment / Good quality and stability for product.

Technical Specification

Configuration

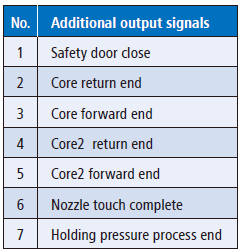

■Signals from IMM to peripheral equipment

Signal selection : Additional 7 items available

Signal channel : Additional 15ch available (STD: 5ch) -> Total : 20ch

Specifications : IMM provides dry A contact or DC24V at additional 15ch.

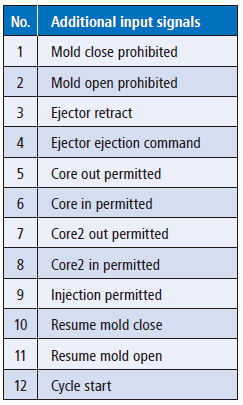

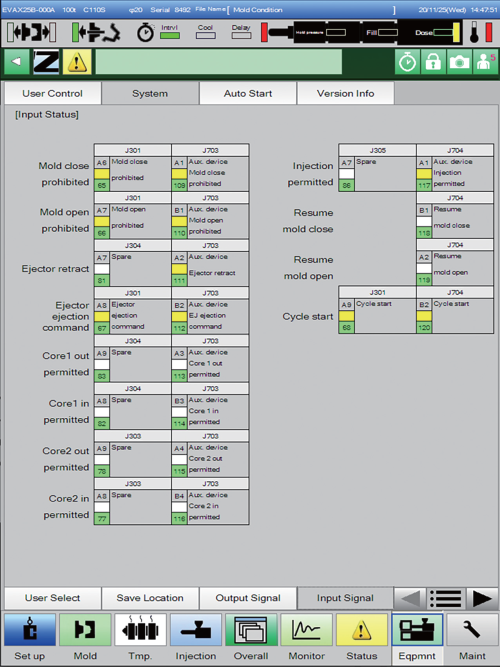

■Signals from peripheral equipment to IMM

Signals : Peripheral equipment can control IMM operation as injection, mold open/close, ejection and core pull.

Specifications : Dry A contact only

Screen

■Input signal confirmation screen IMM shows input signal status on the screen.

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD