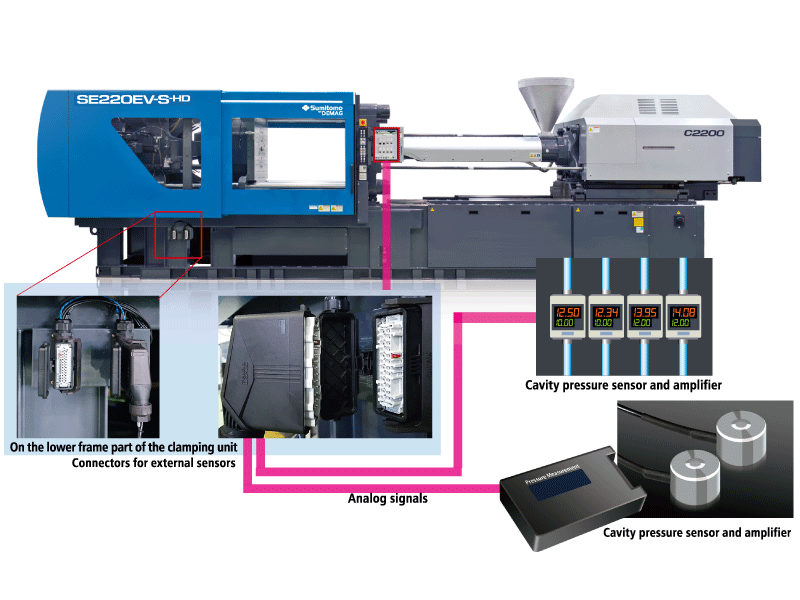

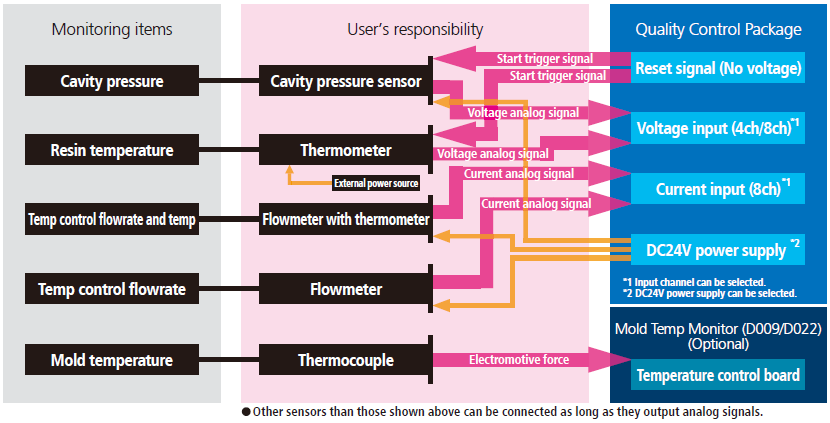

The Quality Control Package is an application package that takes quality control a rewarding step higher, by adding connectors for external sensors to the lower part of the mold clamping unit frame (on the operating panel side). Through these connectors, the analog readings (voltage and current) that external sensors generate for cooling water flowrate, mold internal pressure or other quality-pertinent conditions can be monitored and recorded from the operating panel's waveform viewing and logging windows. This application package provides superior quality control.

Issues

- The traceability of molded products was not ensured.

Solutions

Purpose-specific connectors for connecting analog signals are provided in an easily accessible location on the molding machine frame, which alleviates the users of any tedious cable connections inside power distribution boxes. With every shot, the peak readings from the connected external sensors are recorded as logging data. Moreover, those signals can be selected and displayed as waveforms on the waveform viewing window.

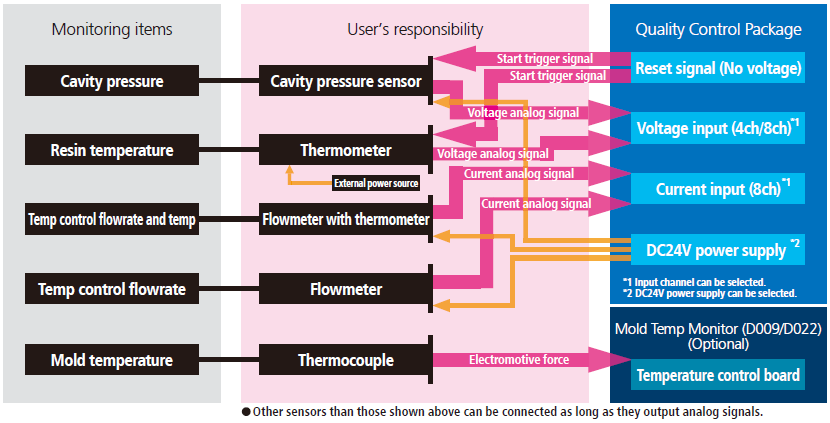

Quality control items such as cavity pressure and temperature can be associated with the logging of the molding machine and be monitored and recorded on the operation screen, enabling more accurate quality control.

It greatly simplifies the troublesome tasks of connecting analog signals to molding machines and converting those signals into workable data.

Example benefits

Analog signals from various sensors can be captured on the molding machine and stored together with other logging data to establish traceability of the molded product.

Technical Specification

Any sensor capable of analog output can be read through these connectors into the data windows of the molding machine's operating panel. Moreover, if needed to drive a sensor amp, 24V of power can be supplied.

Example System

- This example shows a common system.

- Consult with sensor manufacturers as to which sensor to choose and whether a sensor amplifier is needed or not.

Example Windows

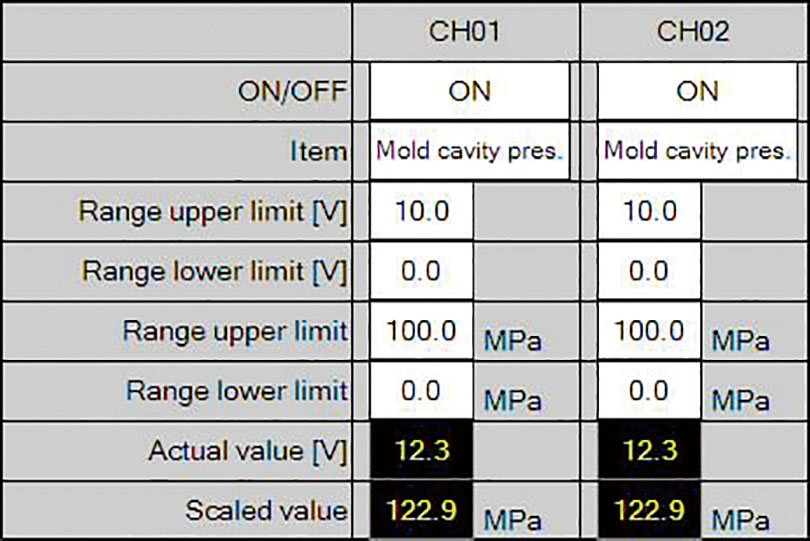

Sensor setting window (Voltage)

- Analog voltage output specifications of cavity pressure sensor:0 - 10V → 0 - 100 MPa

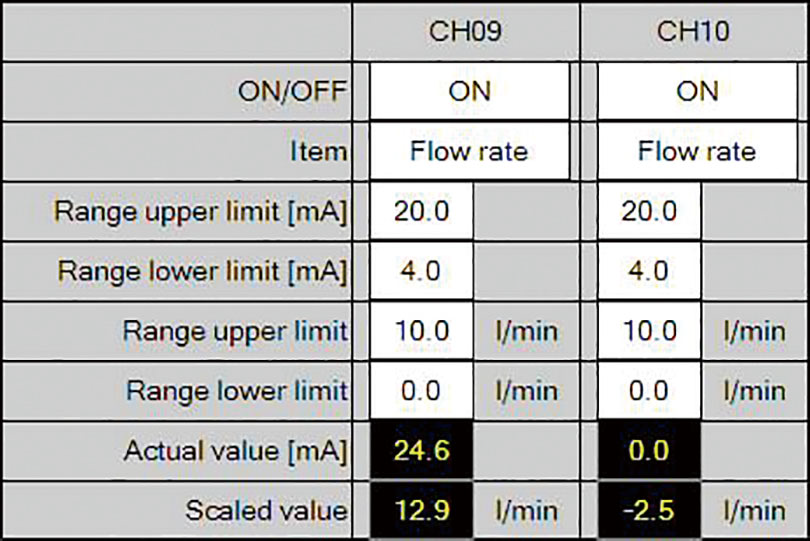

Sensor setting window (Current)

- Analog current output specifications of flowmeter: 4 - 20 mA → 0 - 10 L/min

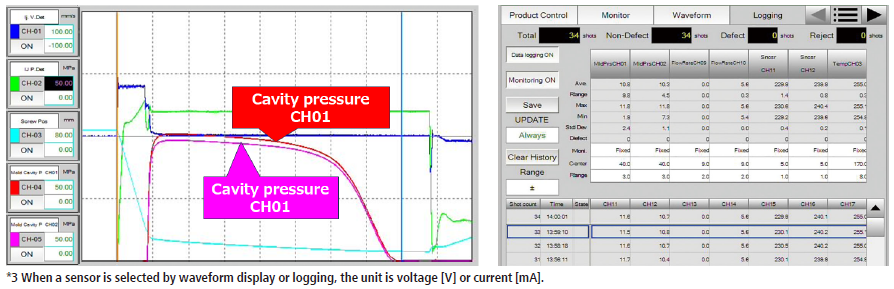

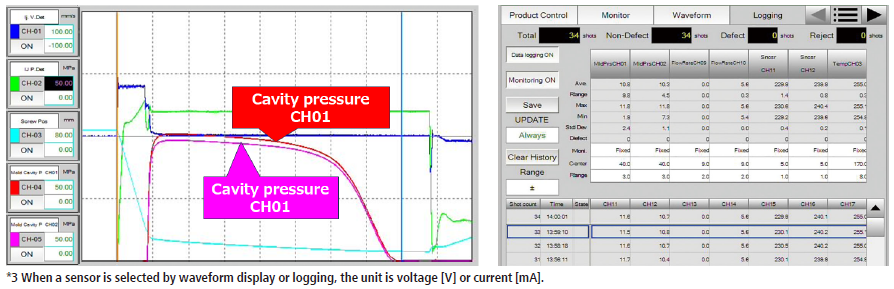

Waveforms

- Waveforms can be displayed for "Cavity Pressure", "Flowrate", "Temperature", and "Sensor". *3

Logging

- Logging can be selected from "Cavity Pressure", "Flowrate", "Temperature", and "Sensor". The peak value from mold close start until hold pressure end are completed can be logged. Judgment of defective can be performed by setting the monitoring items.

*The user prepares and connects the cables for the external sensors.

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD