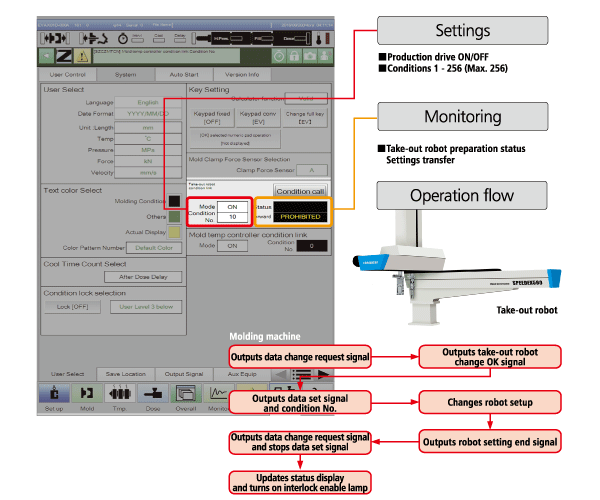

8-bit binary output connects a take-out robot to the molding machine. This allows robot side condition to be saved to the molding machine. Careless mistakes can be avoided, and preparation to start-up time can be reduced.

Issues

Damage of mold and EOAT due to forgetting or mistakenly setting take-out conditions

Solutions

Operating conditions of the take-out robot can be automatically changed when the molding conditions are changed.

Example benefits

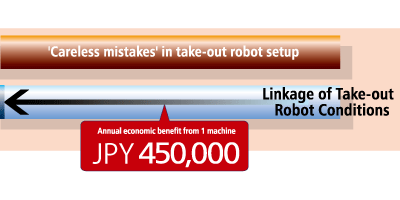

Less production loss by preventing 'careless mistakes'

By eliminating 'careless mistakes' like forgetting to call up the take-out robot conditions or setting the wrong conditions, the cost of repairing damaged molds or EOAT can be reduced.

Estimated annual economic benefit per molding machine: 450,000 JPY

Basis for calculating economic benefit

- Damaged mold caused by setting wrong take-out robot conditions: Twice a year (Total repair costs 300,000 JPY)

- EOAT damage: Twice a year (Total repair costs 150,000 JPY)

Technical Specification

Connection requirements

The molding machine (terminal board inside the control console) and temperature controller connect over an 8-bit binary output cable. Take-out robot conditions are then set and robot operations monitored from the Take-out robot Setup Link pane on the 'System Settings' screen.

- The take-out robot may require remodeling. Contact the take-out robot manufacturer in advance.

- The user procures and provides the 8-bit binary output cable.

Settings

■ Production drive ON/OFF

■ Conditions 1 - 256 (Max. 256)

Monitoring

■ Take-out robot preparation status

■ Settings transfer

- Applicable take-out robot maker:

Star, Yushin, Harmo, Sailor

To connect to non-Japanese brands of take-out robot, please contact us.

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD / SE-EV