This QR code reading application links all of the information needed to set up production -- molding conditions, take-out robot EOAT, resin, user information, and more -- to QR codes that users can scan to call up conditions for molding jobs, verify whether conditions are correct or not, and authenticate users. It makes setup accurate, speedy and mistake-free.

Issues

- Mold damage by calling up wrong conditions

- Damage of EOAT due to mishandling during replacement

- Wasteful production of molded products due to wrong resin verification

- Setting error due to user's unintentional operation

Solutions

Calling up molding conditions

Molding conditions can be automatically called up by scanning QR codes that represent mold IDs. Users are spared the trouble of manually entering conditions.

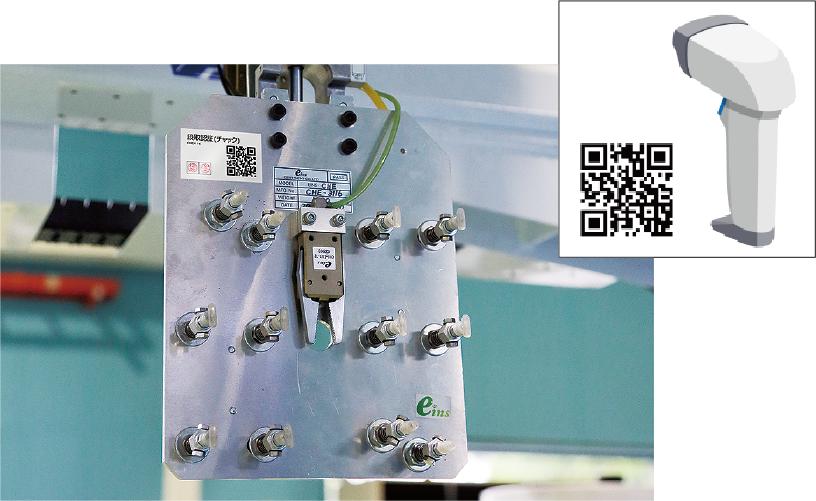

Verifying E.O.A.T

Once molding conditions have been called up, the QR code of the EOAT can be scanned. If the EOAT does not match the molding conditions, continuous operation can be blocked.

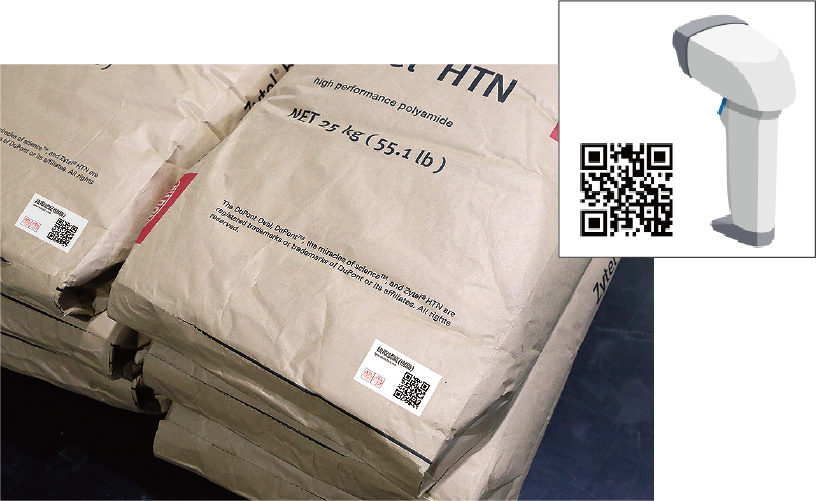

Verifying resins

Once molding conditions have been called up, the QR code on the resin bag can be scanned. If the resin does not match the molding conditions, continuous operation can be blocked.

Authenticating users

Users can be automatically authenticated by scanning the QR code on a nametag or the like that represents the user name, access level and password.

QR codes can be used to authenticate other information.

For more information, please contact us.

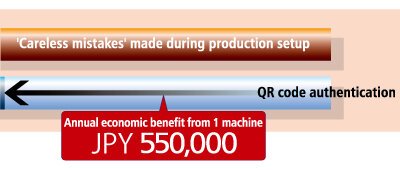

Example benefits

Less setup loss by preventing 'careless mistakes'

Users are spared repair costs for damaged equipment and disposal costs for wasted resin, because 'careless mistakes' made during production setup, e.g., calling up the wrong molding conditions, mishandling of the EOAT during replacement, use of the wrong resin, etc., are eliminated.

Estimated annual economic benefit per molding machine: 550,000 JPY

Basis for calculating economic benefit

- Damaged mold caused by calling up the wrong molding conditions: Twice a year (Total repair costs 300,000 JPY)

- Damage of EOAT due to mishandling during replacement: Twice a year (Total repair costs 150,000 JPY)

- Disposal of molded products caused by using the wrong resin: 3 times a year (Total wasted product 100,000 JPY)

Technical Specification

- This application is offered as an option. The user is responsible for procuring a QR code reader (USB connection) and preparing QR codes.

- Applicable QR reader: Keyence HR-100 (Wired type) / Keyence HR-101B (Wireless type) (This model is not shown in photos.)

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD / SE-EV