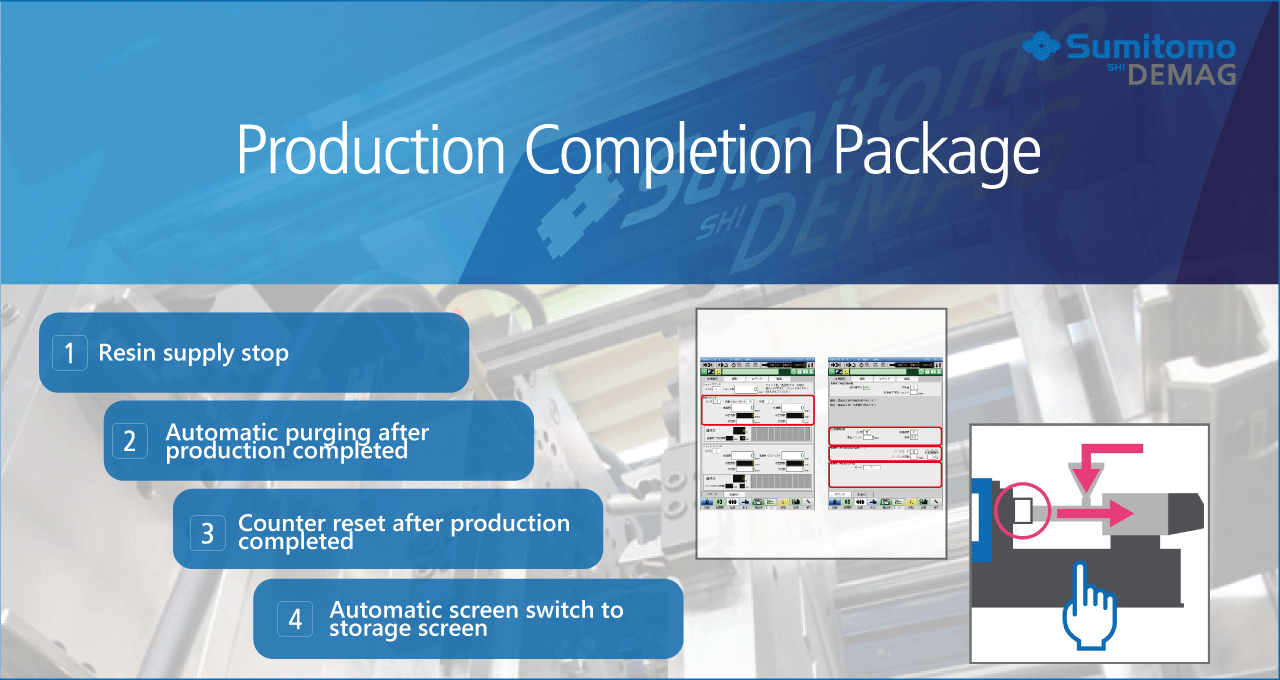

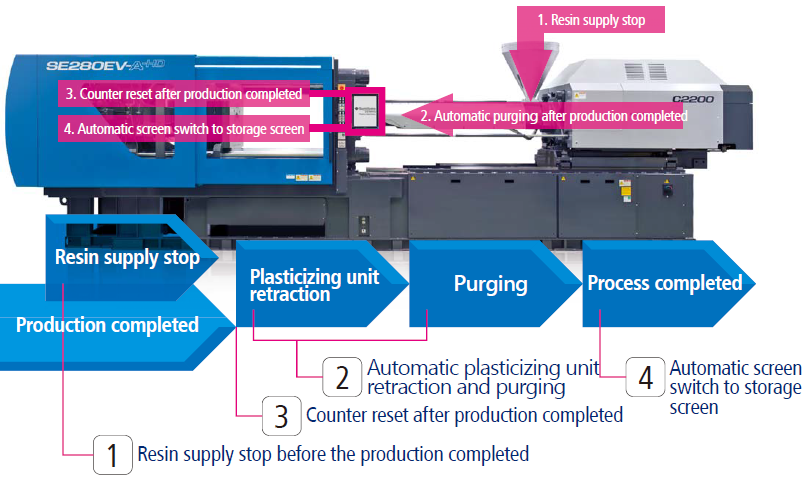

Production complete processes are carried out by IMM automatically. It reduces set up time and prevents carless mistakes.

Issues

- Many processes to be handled at the completion of production, resulting in high labor costs

- Costly due to extra resin supplied in the final process

Solutions

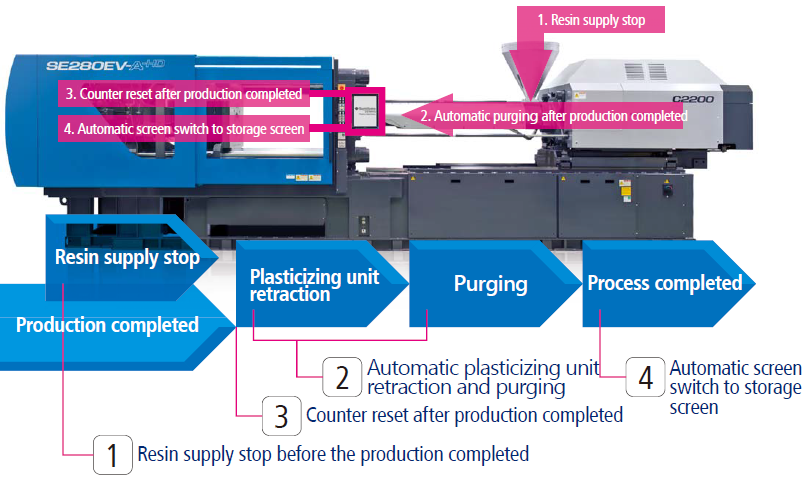

Before production complete, the resin feeder stops.

Then IMM automatically performs IJ unit retraction and purging after the production compleation.

Four functions proceed along the process.

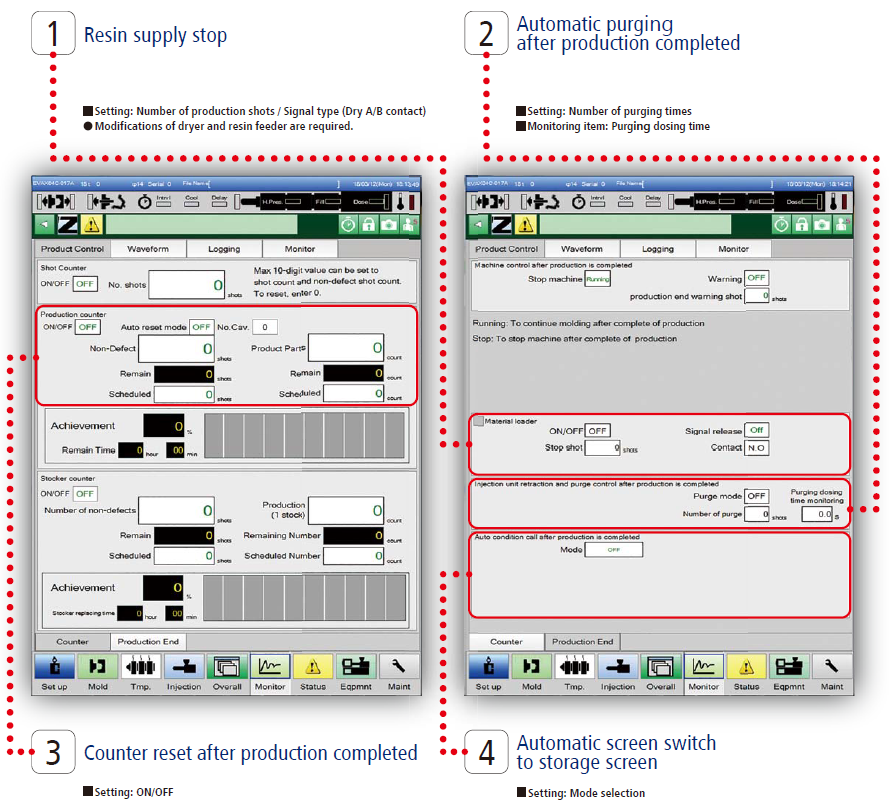

1.Resin supply stop

Before production complete, IMM sends the signal to resin feeder for resin supply stop.

2.Automatic purging after production completed

After production completed, the IJ unit automatically retract and perform purging.

3.Counter reset after production completed

After the current production run ends, the production count is automatically reset.

4.Automatic screen switch to storage screen

After purging ends, the Molding Conditions Screen is automatically displayed.

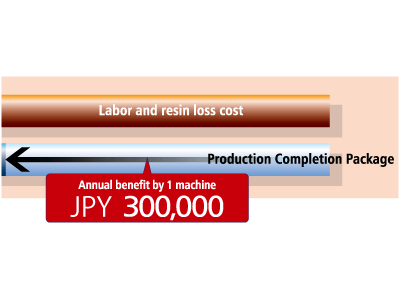

Example benefits

Production loss reduction by "Production Completion Package"

You can save labor cost and resin loss by automatic sequence after production completed.

Basis for calculating economic benefit

- Labor Costs During Molding Machine Downtime:

25 minutes x 200 times per year = 250,000 JPY

- Wasted Resin:

500g (POM) x 200 times per year = 50,000 JPY

Technical Specification

Purging saucer [C052]

Recommended option, available model:SE-EV-S-HD / SE-EV-A-HD

With Production Completion Package, purging saucer is recommended to collect scattered resin.

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD