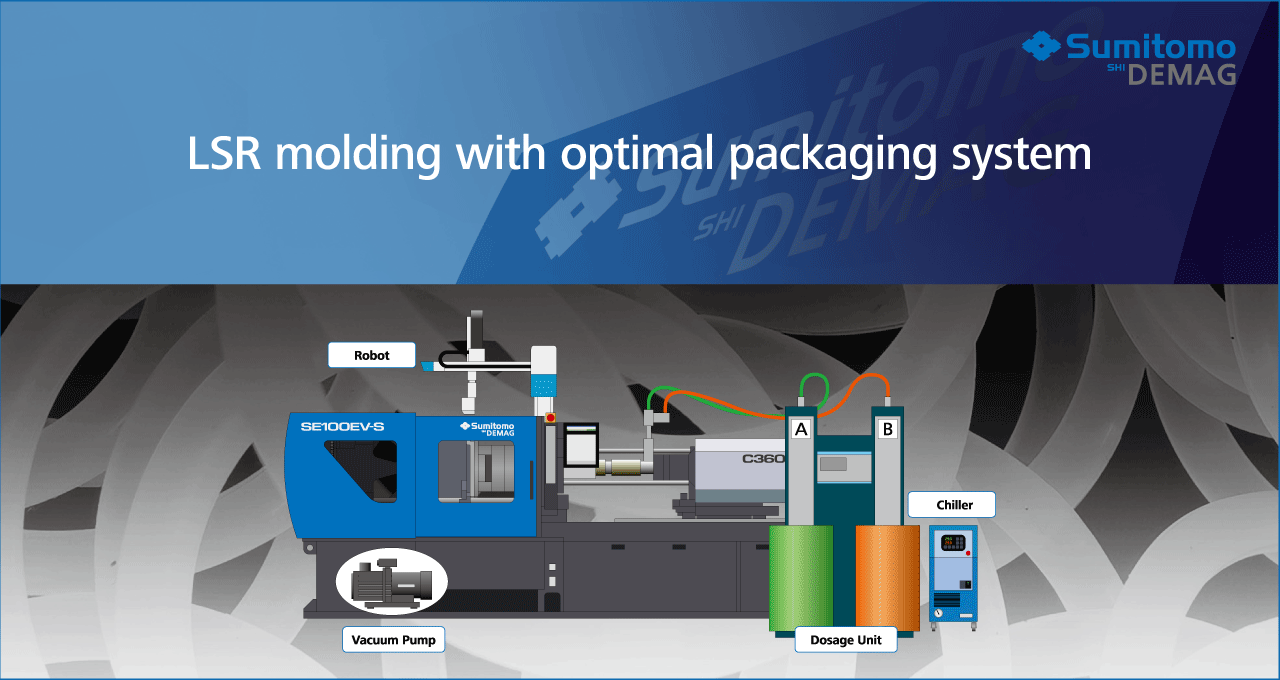

We offer a complete package with strong peripheral equipment partnerships.

Sumitomo's Precision Technology Solutions

LSR molding has unique challenges.

Sumitomo's all-electric injection molding machines provide stable production of LSR with advanced and precise technical solutions.

LSR molding specific issues

- Short shots, sink marks, appearance defects, flash and take-out defects due to filling fluctuations.

- Short shots, flash and cavity imbalance due to surface pressure fluctuations or material viscosity inconsistencies and viscosity changes over time.

Reduced mold life due to deformation.

- Short shots and burnings due to poor ventilation.

- Reduced mold life due to mold deformation.

Sumitomo's Solution Technologies

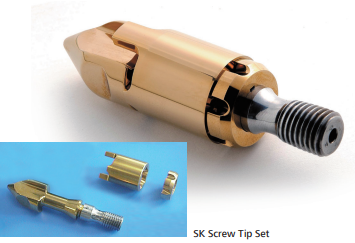

- SK Screw Tip Set and High-precision Injection Control, eliminates variations in filling and achieves precise and stable molding.※Point 1

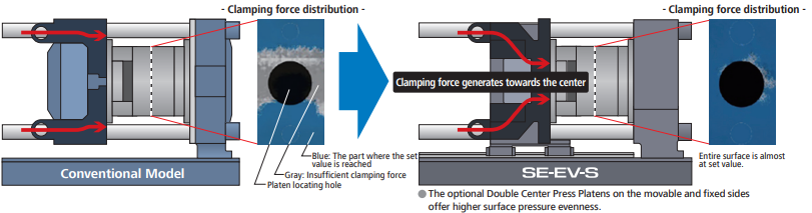

- High-precision Clamping Mechanism equalizes surface pressure distributions and improves the cavity balance.※Point 2

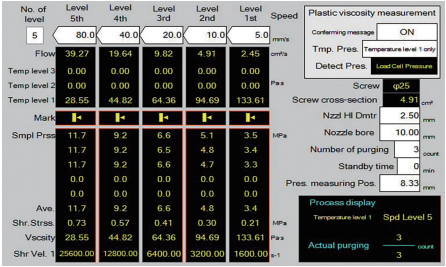

- Material Viscosity Measuring Function reduces inconsistencies in material viscosity and mitigates changes in viscosity over time.※Point 3

- Control Circuits/piping for Special Vacuum Pumps and High-precision Mold Closing Pause Function

- High Rigidity Clamping Mechanism and Minimum Clamping Force Detection Function

Solution Details

Point1 SK Screw Tip Set and High-precision Injection Control

Due to the low viscosity of LSR, the sealing property of the screw tip is important. The SK Screw Tip Set blocks the material flow path by counter rotating the screw, eliminating backflow during filling and stabilizing metering. In addition, the high-precision injection control provided by the standard direct drive system enables quick and complete sealing capabilities.

This enables precision stable molding even with small injection volumes.

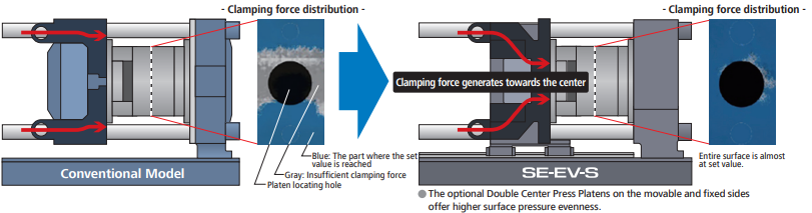

Point2 High-Precision Clamping Mechanism (Center Press Platen)

Standard installed Center Press Platen to equalize surface pressure distributions.

A unique structure design reduces surface pressure unevenness and improves cavity balance.

Point3 Material Viscosity Measuring Function

Material Viscosity Measurement Function is included as standard equipment.

Material viscosity can be measured at any screw speed level.

This feature helps reduce fluctuations in production stability due to differences in material lots.

Benefits

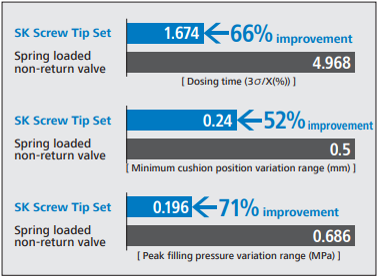

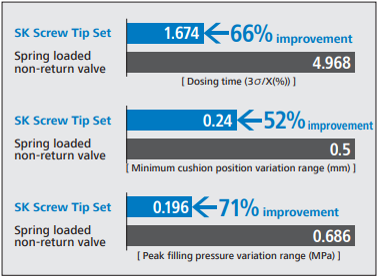

Below is a more detailed explanation about the effects of the 'SK Screw Tip Set and High-precision Injection Control' introduced in Point 1.

Improved molding accuracy and stability

Compared to the spring loaded non-return valve used in typical LSR injection molding machines, the SK Screw Tip Set offers greatly improved dosing and filling stability.

【Comparison of precision stability】

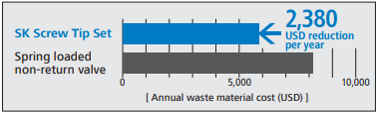

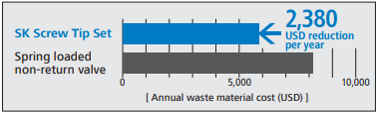

Reduced waste material

The increased yield of good products due to stable dosing reduces defective products = waste material and significantly lowers production costs.

※All data in the graphs are actual measured values under the following conditions.

Product: Medical O-ring

Size : Outer dia. 44 mm/Body dia. 3 mm

Number of cavities : 16

Product weight : 1.17 g

Injection weight : 21.2 g

【Reduction of waste material costs】

※Exchange rate: 1 USD = 150 JPY

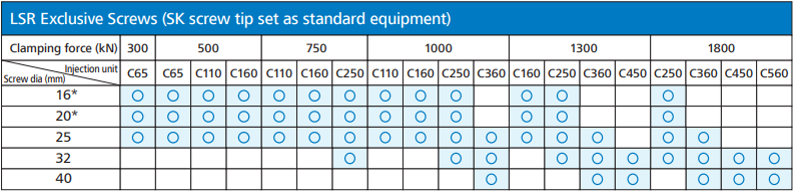

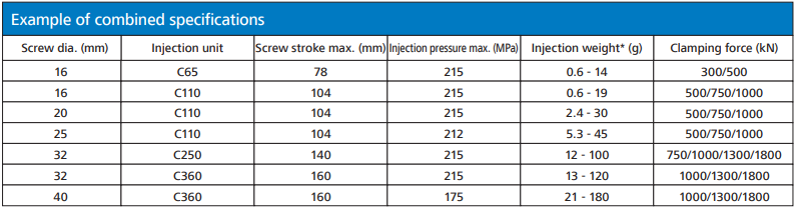

Product Composition

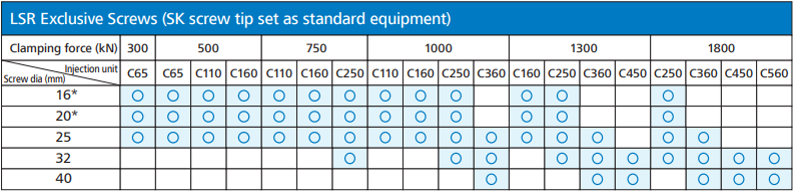

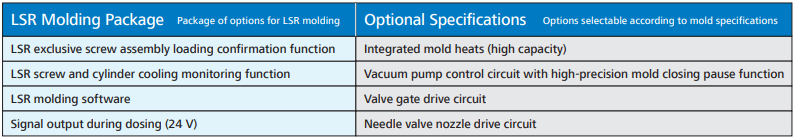

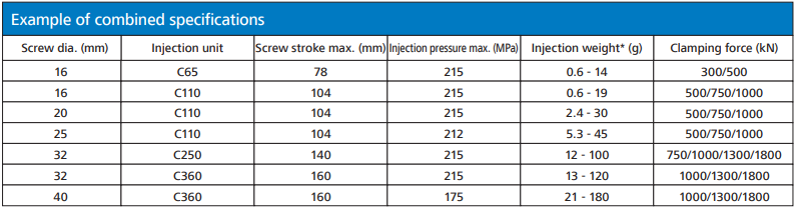

Based on the SE-EV-S series of all-electric injection molding machines,a wide variety of LSR exclusive screws are also available.

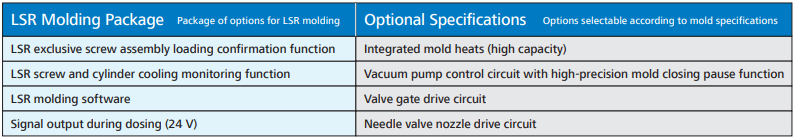

The "LSR Molding Package" combines the necessary specifications for LSR molding, while the "Optional Specifications" can be customized according to mold specifications.

We can build the best system to meet your needs.

●For details on LSR Molding Package and Optional Specifications, please contact us.

●For details on LSR Molding Package and Optional Specifications, please contact us.

●*Injection weight is for reference only.

●*Injection weight is for reference only.

Other Available Models

Compatible with Double-shot/Vertical molding

Composite molding of LSR with different materials and vertical molding are also available.

They expand the possibilities of LSR molding and contribute to the development and production of new products.

Contact Us

Our team is pleased to provide you with extensive information regarding LSR molding.