All-electric Vertical Rotary Type Injection Molding Machine

This vertical rotary molding machine performs insert molding with engineering plastics and super-engineering plastics.

It is equipped with an SL screw and large, high-speed rotary table that combine to deliver precision, fast-cycle molding.

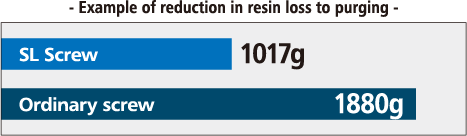

Lower material costs owing to smooth melting

SL Screw System

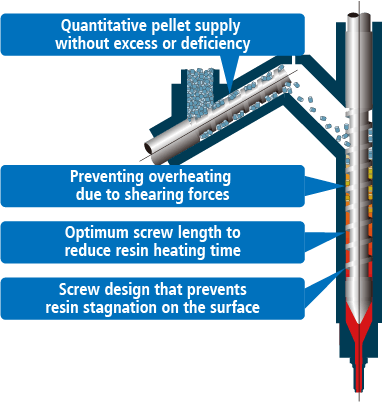

The SL Screw System prevents resin stagnation and shearing.

It was designed by visually analyzing resin melting behavior with respect to temperature and pressure.

The SL screw helps improve yield by eliminating issues caused by entrapped gases such as short shots and mold deposits. It also serves to eliminate spotting and discoloring. It is the right tool for molding with engineering and super-engineering plastics.

Because resin is stably melted and protected against thermal degradation, users do not lose resin to wasted shots.

The SL Screw saves on resin when changing product colors, too.

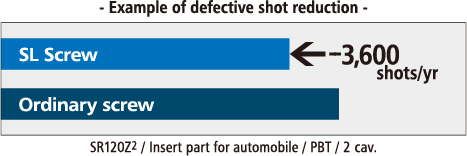

Shots of defective parts were reduced by improving mold deposits.

When converted to CO2, it decreased emissions by 572 kg for the year.

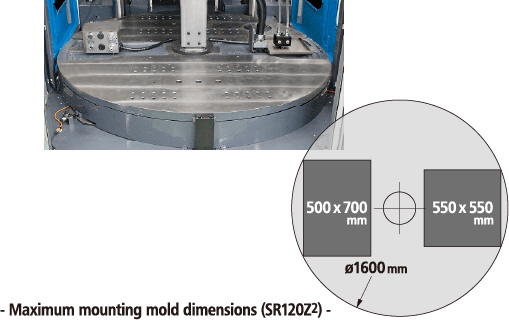

Accommodates larger molds

High performance rotary table

Despite the compact frame, the machines come with a large rotary table.

It allows users to mount larger molds and apply their composite molding skills to bigger products.

Stable filling even with high volume injection

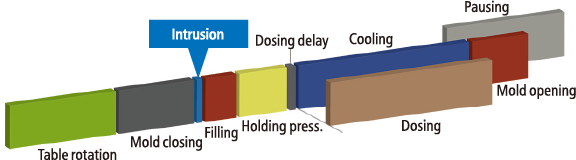

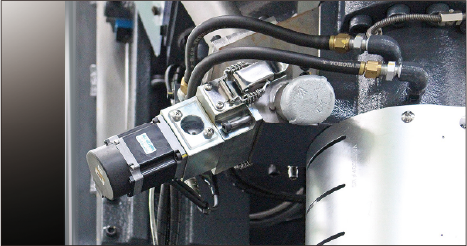

Refilling control Intrusion Option

”Intrusion” filling control keeps filling stable even with products that require large amounts of resin.

Any anticipated resin shortfalls are made up during screw rotations prior to resin injection. Set up is simple requiring the user to enter just the screw RPM and allotted rotation time.