All-electric Vertical Rotary Type Injection Molding Machine

The SR-Z series comes equipped with a large,

high-speed invertible rotary table.

It is more than ready for high-caliber composite molding

with engineering and super-engineering plastics.

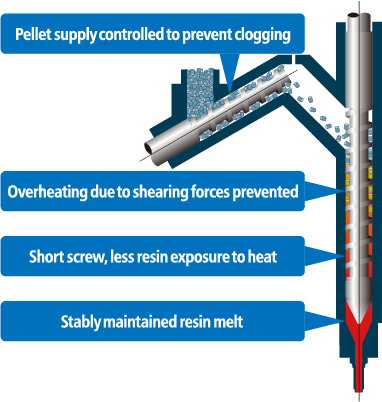

Lower material costs owing to smooth melting

New theoretical plasticization

The SL Screw prevents resin from stagnating in the flow channel, thus avoiding undesirable overheating that can

cause resins to carburize. Moreover, because the screw is short, the resin is exposed to heat for considerably

less time.

The SL screw helps improve yield by eliminating issues caused by entrapped gases such as short shots and mold deposits. It also serves to eliminate spotting and discoloring. It is the right tool for molding with engineering and super-engineering plastics.

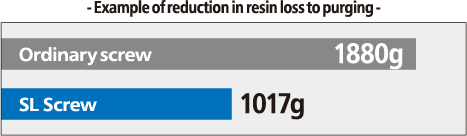

Because resin is stably melted and protected against thermal degradation,

users do not lose resin to wasted shots.

The SL Screw saves on resin when changing product colors, too.

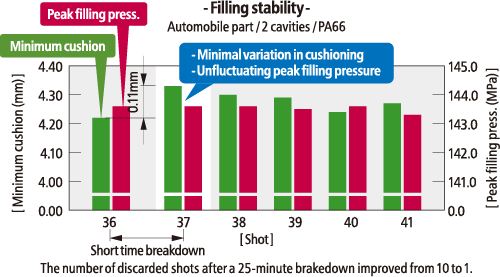

Because the SL Screw even minimizes resin degradation during minor trouble that can halt production for 10 - 20 minutes, users have to discard far less shots. Moreover, it works great with color changes because it eliminates a good portion of the purging needed with conventional screws.

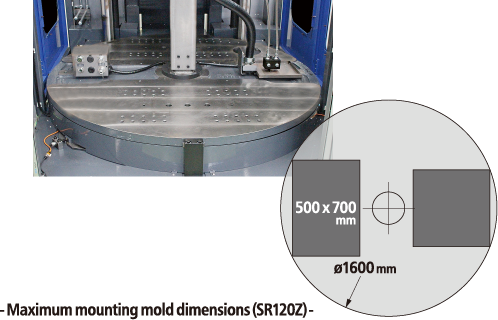

Accommodates larger molds

High performance rotary table

Despite the compact frame, the machines come with a large rotary table.

It allows users to mount larger molds and apply their

composite molding skills to bigger products.

Stable filling even with high volume injection

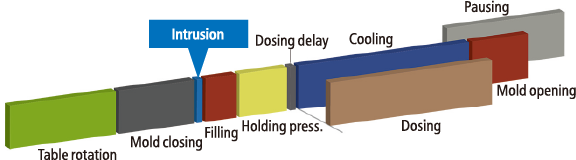

IntrusionRefilling control Option

”Intrusion” filling control keeps filling stable even with products that require large amounts of resin.

Any anticipated resin shortfalls are made up during screw rotations prior to resin injection. Set up is simple requiring the user to enter just the screw RPM and allotted rotation time.