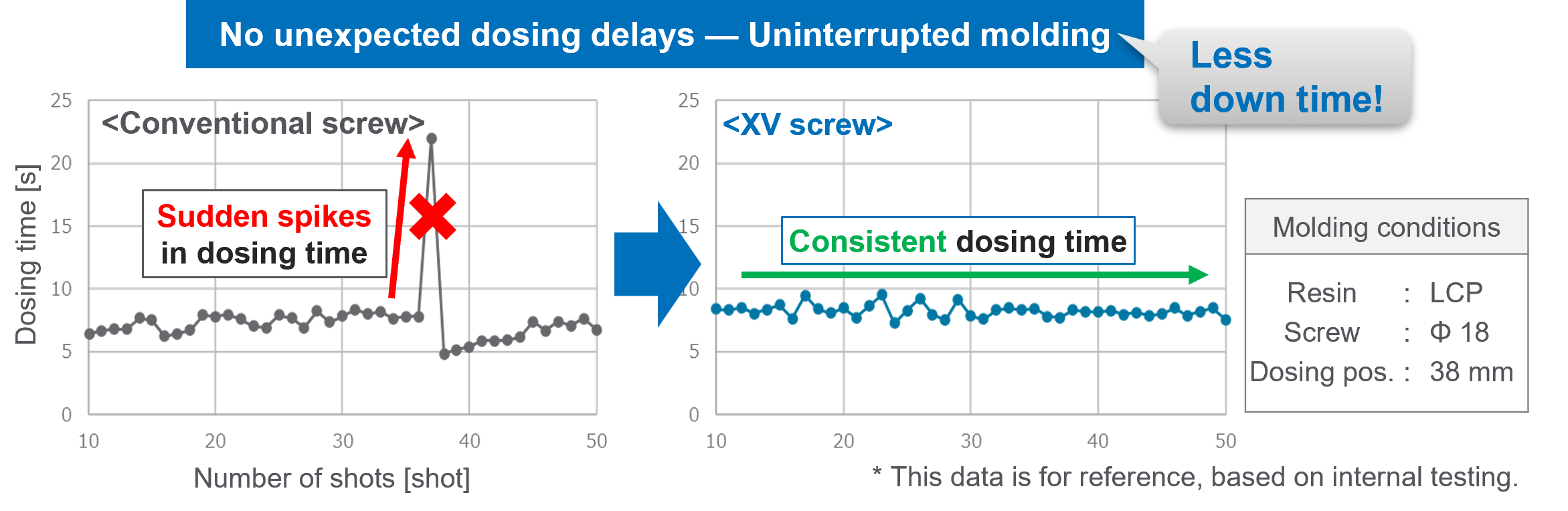

We have launched the XV Screw (Expanded Volume Screw), designed for high-volume molding of LCP resin, which is widely used in connector components. It prevents machine stoppages caused by sudden fluctuations in dosing time and improves mass productivity.

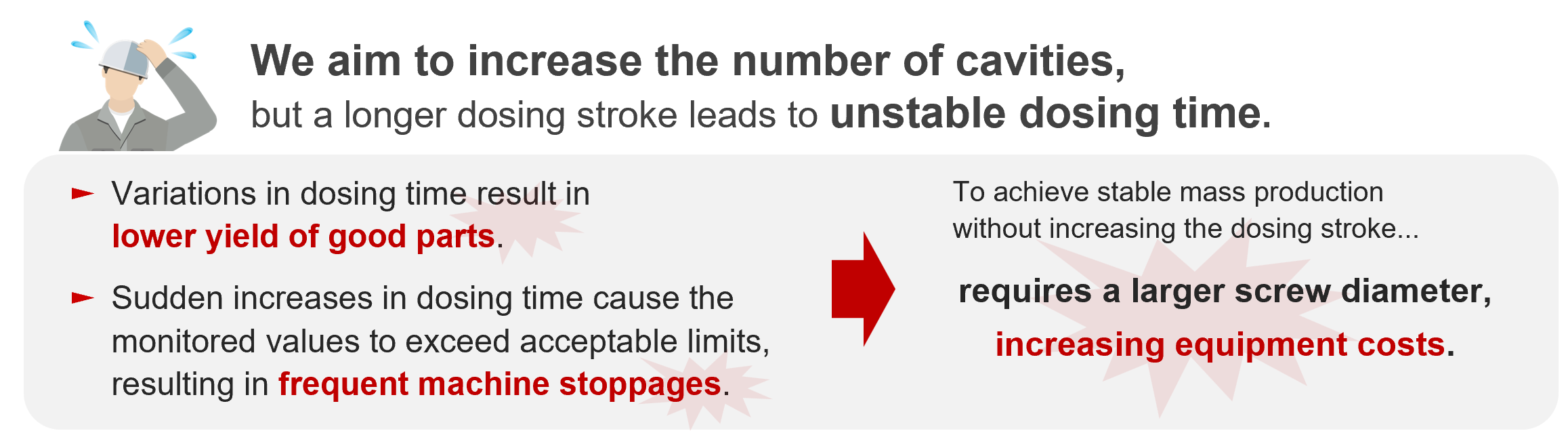

Challenges in LCP molding

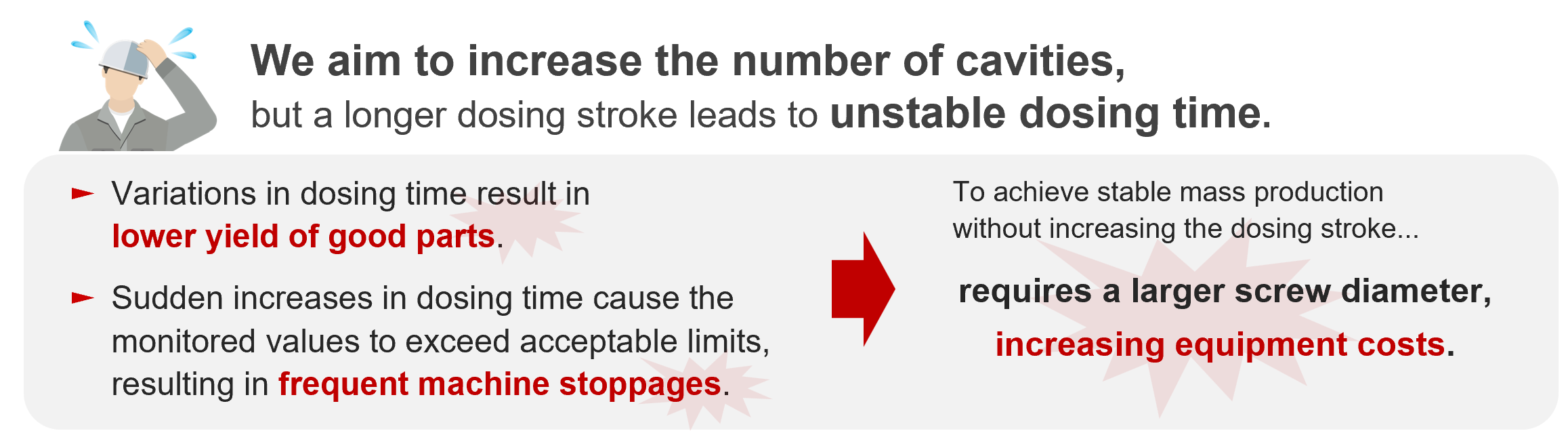

LCP has low resin viscosity, making it difficult to stabilize dosing time. Increasing the number of cavities results in a longer dosing stroke, which makes dosing unstable. To achieve stable mass production, the screw diameter must be increased--but this results in higher equipment costs.

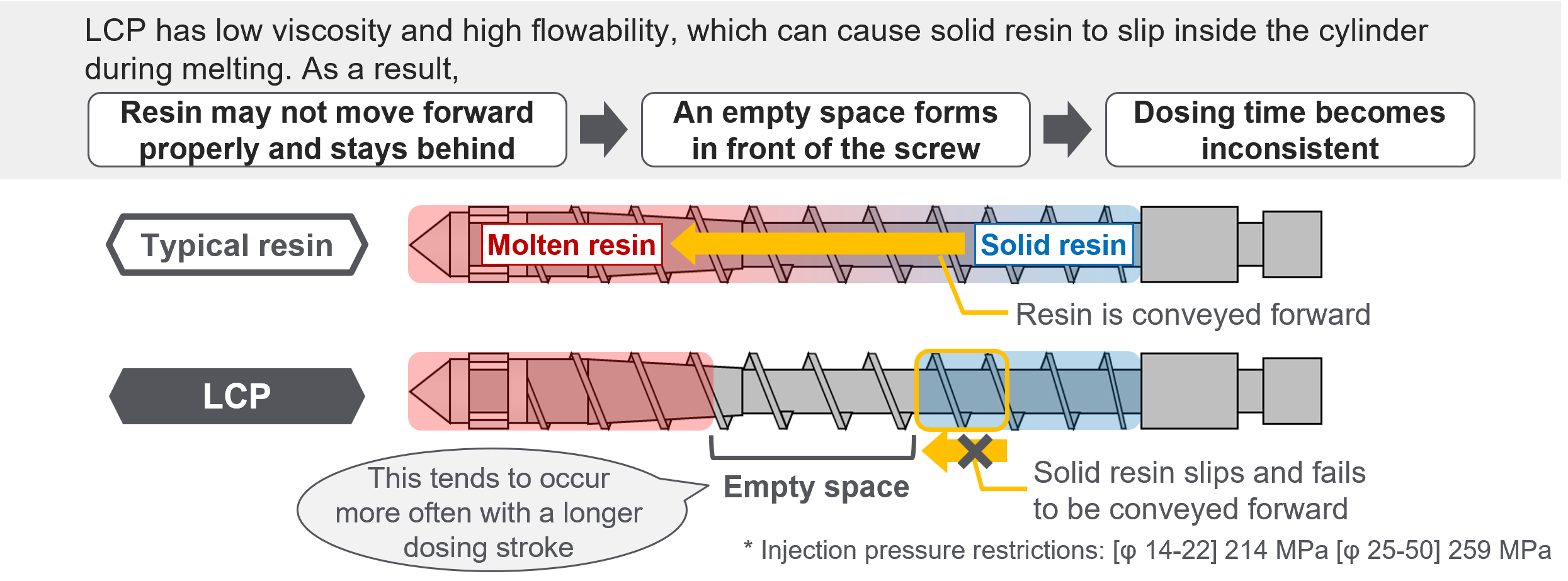

Screw design focused on slippage of low-viscosity resins

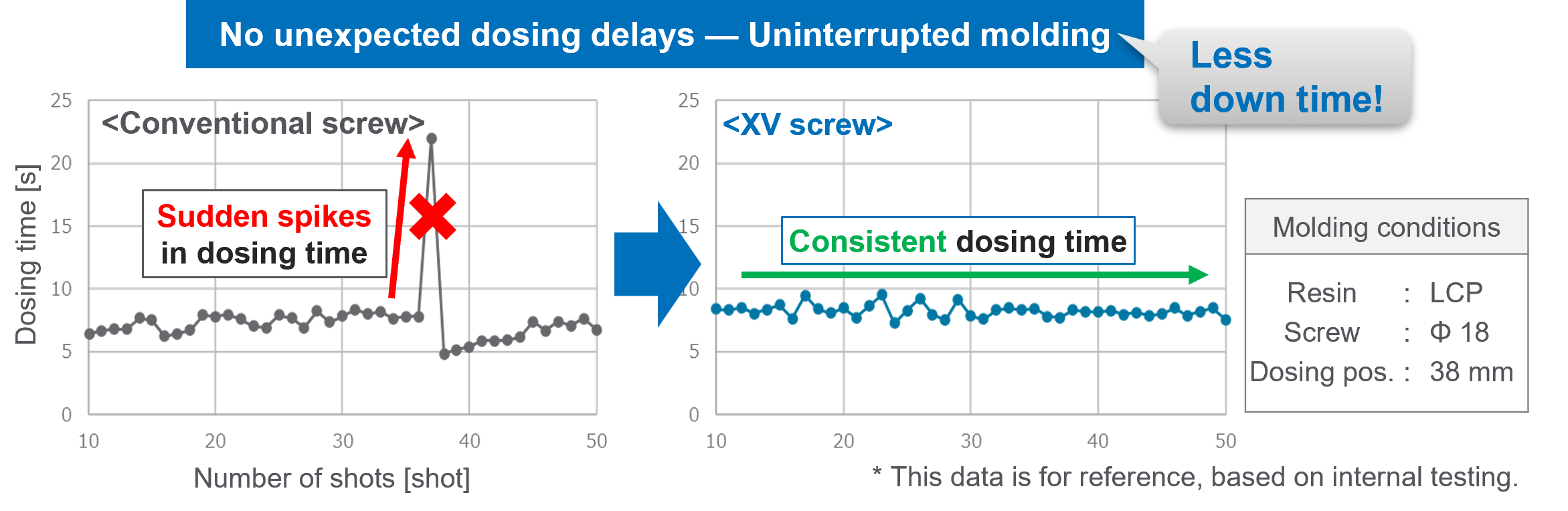

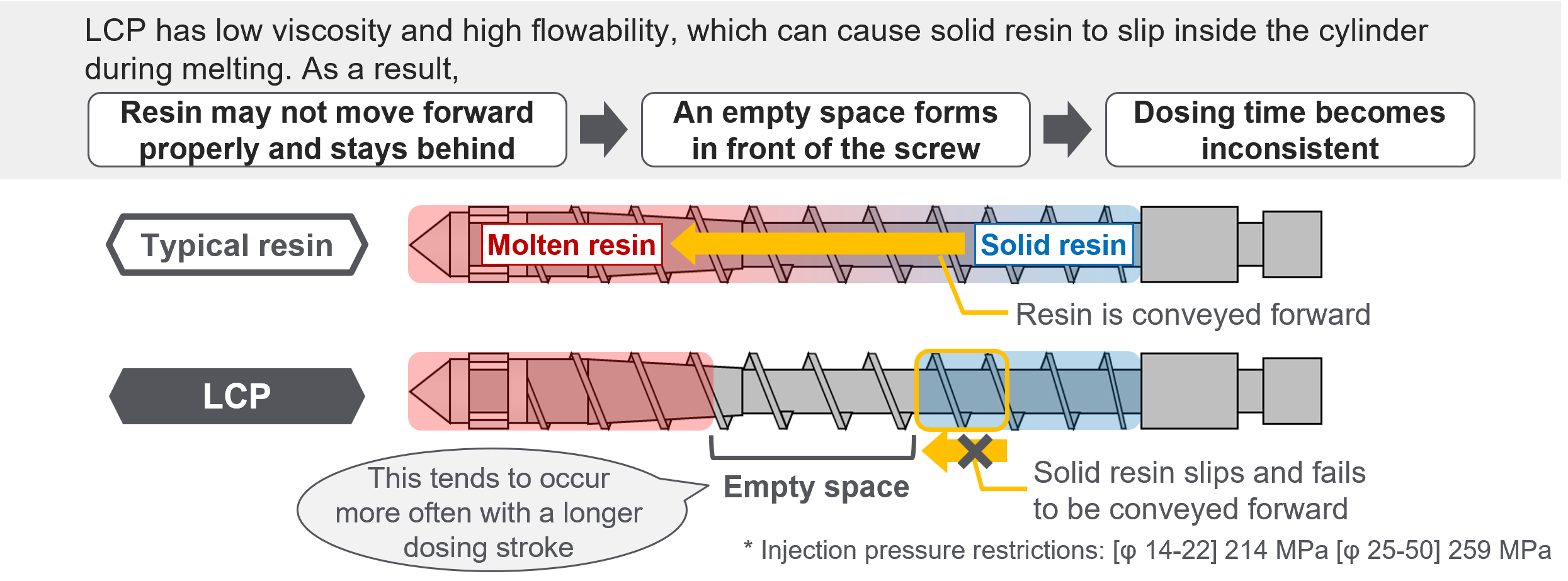

LCP, a low-viscosity resin with high flowability, tends to cause slippage of solid resin inside the cylinder during the melting process. This can lead to the formation of empty spaces and result in variations in dosing time. The XV Screw addresses this issue by focusing on "resin slippage" and adopting a design that suppresses it, enabling stable resin conveying.

Molding case

The XV Screw is effective not only for LCP but also for dosing stability in other low-viscosity resins such as PA. With the advancement of autonomous driving and AI, demand for products using LCP--such as connectors--is expected to grow. As a result, the need for increased cavity numbers and reduced downtime to improve productivity is anticipated to become even stronger.

Stable production requires not only the screw itself, but also appropriate process settings and effective use of features. If you are considering increasing the number of cavities for LCP molding or are facing challenges with dosing variation, please feel free to consult with us. For those interested or wishing to request a quotation, please contact us.

Applicable models

Compatible with all models, either through new installation or modification (screw diameter Φ14-Φ50)

*Except for the SE-EV-S-SHR series.

Contact us

For any questions regarding this article, please contact us here.