Company Profile

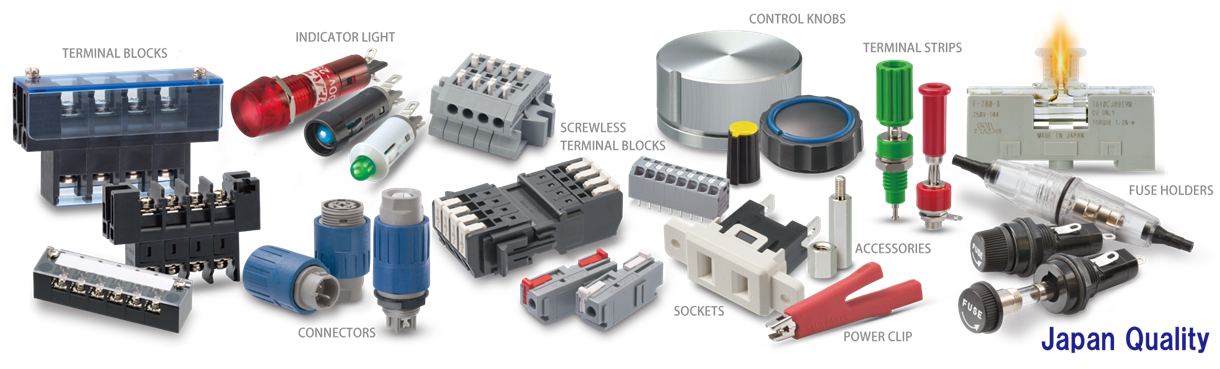

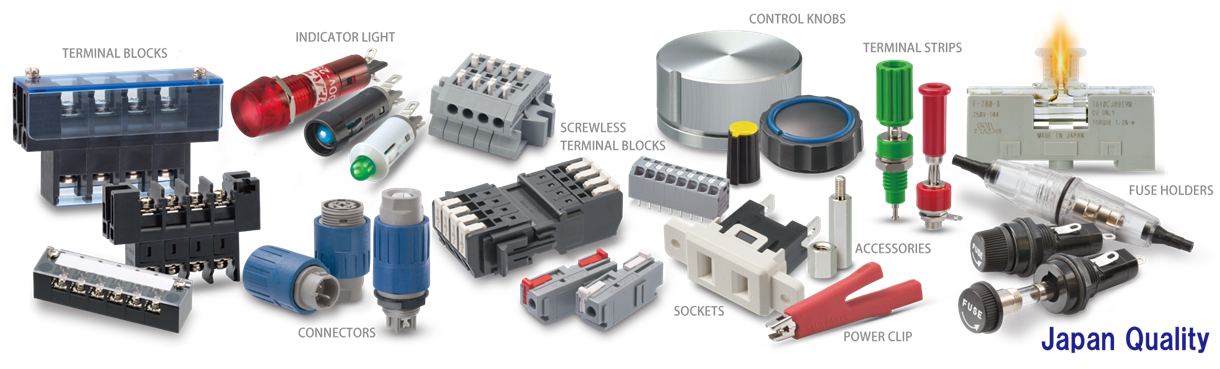

SATO PARTS CO.,LTD. is a manufacturer of terminal blocks, used in various social infrastructure facilities. The company has been manufacturing and distributing electrical and mechanical components supporting the electronics industry for over 70 years. The company responds to customer needs with a flexible sales system that enables short delivery times based on current stock and offers a wide range of products with no lot restrictions. The screwless terminal blocks are available in a wide range of colors to match the on-site wiring colors. The company offers products preventing incorrect wiring and useful for circuit identification.

Factory of SATO PARTS CO.,LTD.

Factory of SATO PARTS CO.,LTD.

From left to right: Mr. Ogata, Mr. Yuuki, and Mr. Sato, who we interviewed for this article.

From left to right: Mr. Ogata, Mr. Yuuki, and Mr. Sato, who we interviewed for this article.

Customer issues

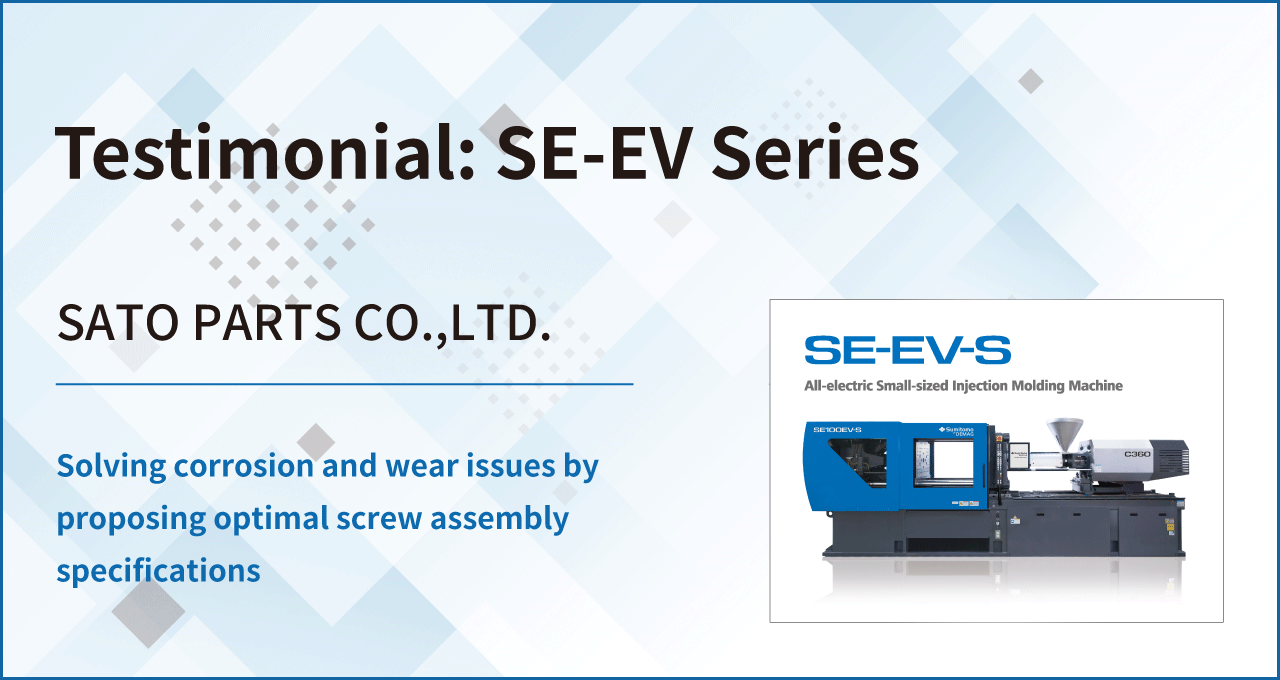

Nylon is a highly hygroscopic resin, which means it is prone to generating corrosive gases if not properly dried. SATO PARTS CO., LTD. uses resins that are more susceptible to wear, thereby affecting the heating cylinder, screw, and non-return valve. This has been a significant issue for them.

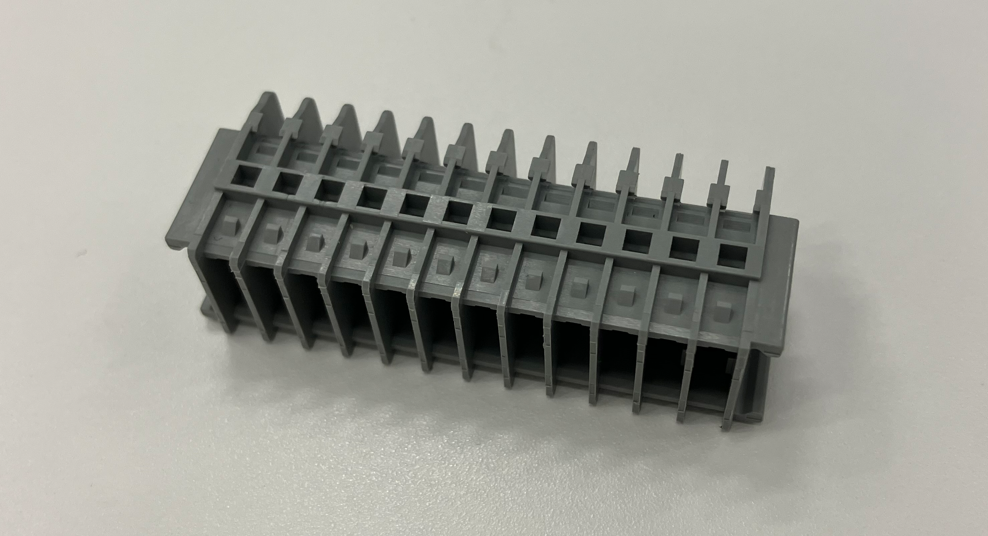

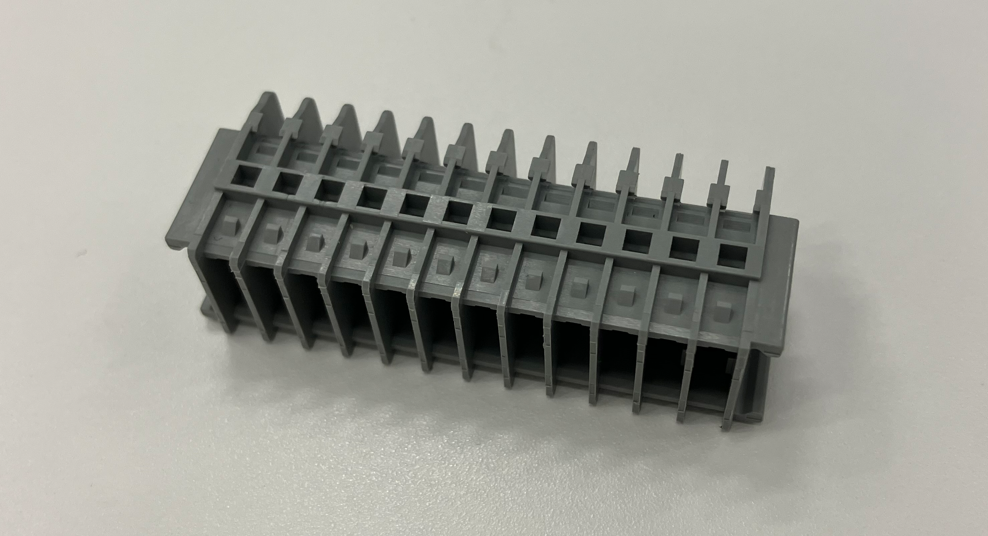

Screwless terminal block

Screwless terminal block

Resin: Nylon

Our proposal to address the issues

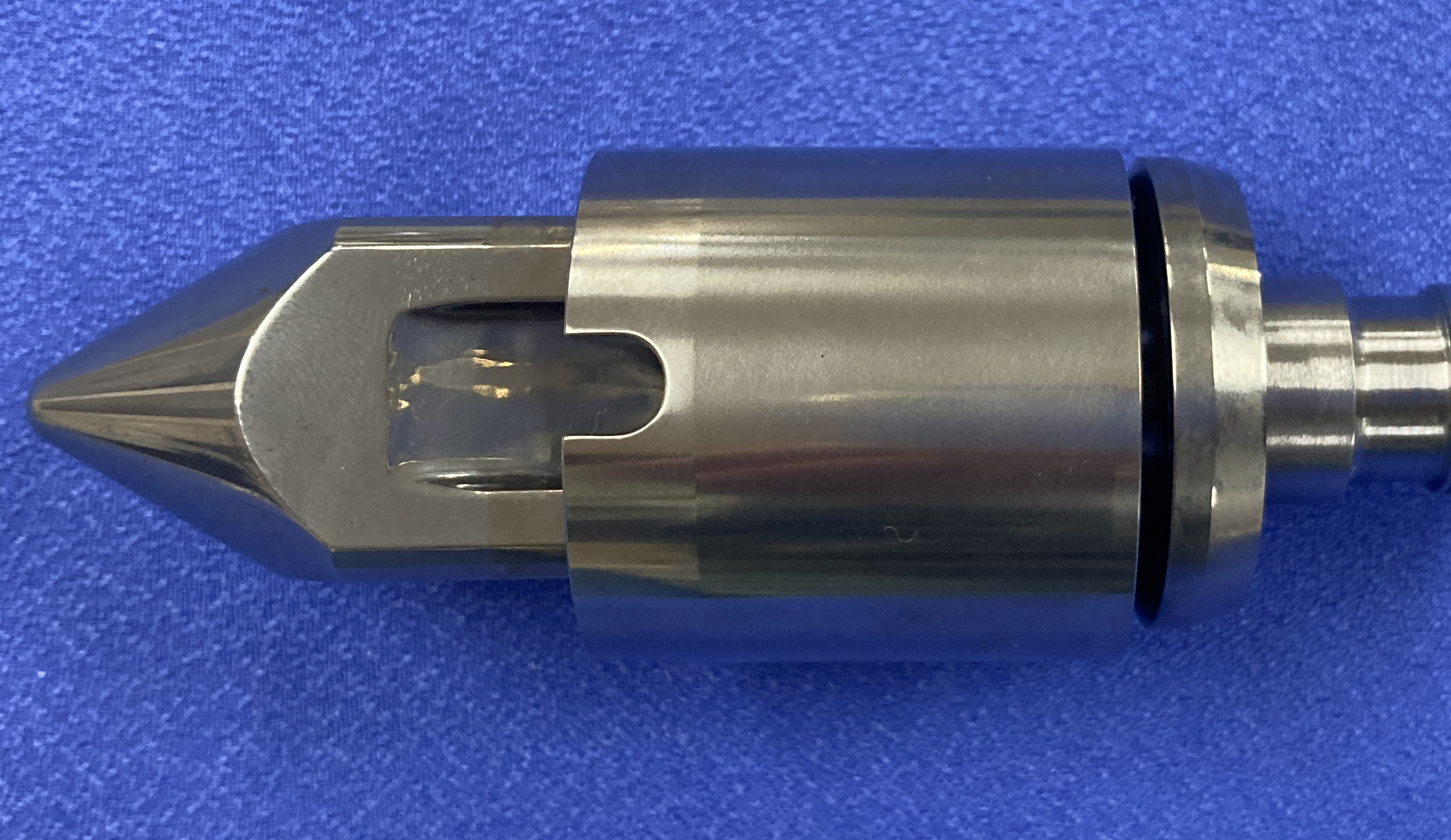

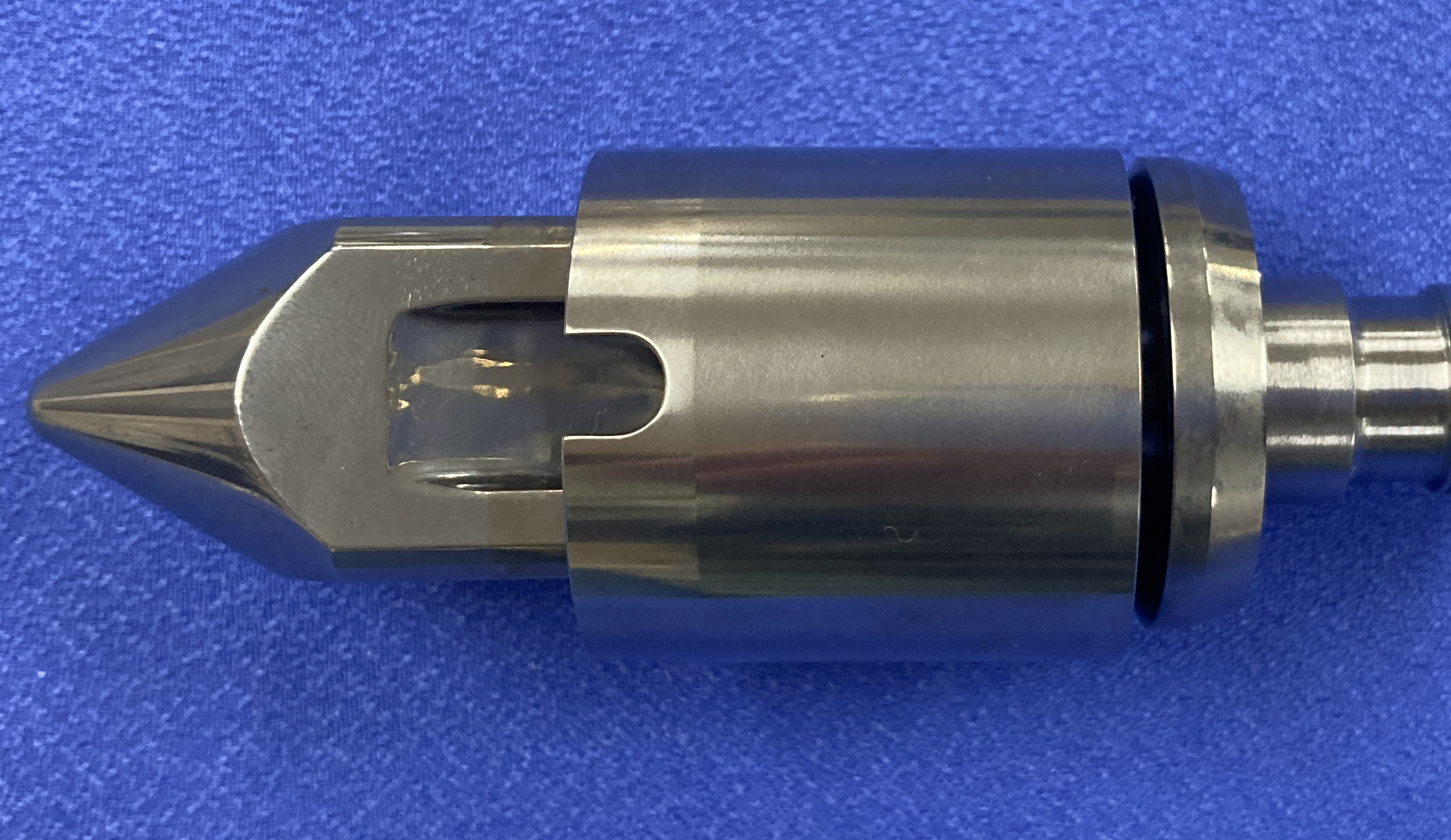

We proposed a screw assembly that demonstrates the best corrosion and wear resistance in our screw lineup. Additionally, we introduced a non-rotating type non-return valve designed to prevent wear inside the heating cylinder. This valve features a clawless check ring, making it less susceptible to wear on its outer circumference.

Non-rotating type non-return valve

Non-rotating type non-return valve

1: Stable molding reduces worker burden

Corrosion and wear of the screw parts led to unstable molding, causing short shots due to backflow. The machine operators had to adjust parameters such as the dosing end position, V-P switchover position, and pressure holding settings of the molding process to resolve this issue.

However, adjusting these parameters changes the way pressure is applied to the molded product. As a result, the tolerance range of parameters became narrowed and, as wear progressed, the machine operators had to make more precise adjustments, which placed a burden on them.

The offered screw parts have eliminated corrosion and wear, enhancing the stability of the molding process. The occurrence of short shots has also been reduced. We have received the feedback from SATO PARTS CO.,LTD. stating 'the molding process can be continued with the initial set parameters, and the supervisor is no longer called by the machine operators'.

2: Reduction of parts replacement costs

Due to corrosion and wear, the non-return valve needed to be replaced every six months, while the heater cylinder and screw required annual replacement, resulting in high costs for parts and services.

SATO PARTS CO., LTD. mentioned, 'It's been about three years since we started the production using the SE-EV series machine, and we haven't had to replace the screw parts even once'.

3: Increased production efficiency with less hassle

When the logging data exceeded the threshold values, the machine operators had to adjust the parameters. Moreover, the replacement of screw parts had to be carefully planned, considering the impact that a production stoppage would have on delivery dates.

According to the feedback received from SATO PARTS CO.,LTD, the number of such issues has decreased, alleviating the labor shortage.

Expert support: Our molding engineers ensure seamless function utilization after machine installation

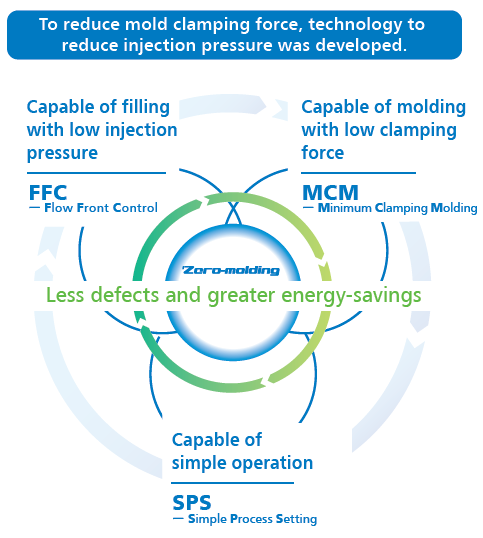

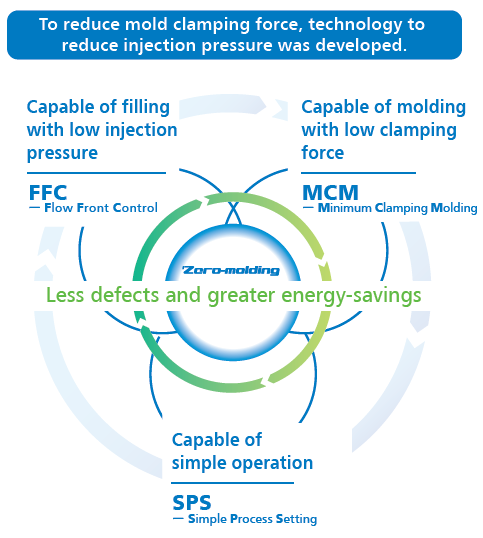

Empower your production with Zero-molding - Reducing defects, Saving energy

Mr. Yuuki, whom we interviewed this time, considered that 'the clamping force should be set higher' to prevent defects such as flashes and others.

Sumitomo Heavy Industries' injection molding machines are equipped with "Zero-molding", a comprehensive application that helps to reduce defects and save energy by operating with low clamping force and low injection pressure. In particular, the Flow Front Control function enables smooth filling with low injection pressure utilizing the viscoelasticity of resin by screw control before and after V-P switchover.

Additionally, the minimum clamping force detection function automatically detects the minimum clamping force required for the mold parting line to be fully sealed using a clamping force sensor, making it easier to determine the necessary minimum clamping force. To utilize these functions, our molding engineers supported machine operations at the actual molding environment. As a result, we saw a reduction in both flashes and gas burns. By halving the mold clamping force from 400kN to 200kN, the rising electricity costs were also lowered. We have received positive feedback from SATO PARTS CO., LTD., stating that 'the molding situations have improved significantly.'

Quickly resolve issues with remote molding assist services

We are currently testing a service that lets us view the molding machine screen of our customers machine online in real-time, and offer molding support. SATO PARTS CO., LTD. has kindly agreed to participate in testing this service, and we are assisting them with process adjustments.

As a specific example, while checking the quality control logging screen online together, we discovered a shot with a long filling time. Upon checking the waveform screen, we found that the injection pressure was rising from the beginning. We suspected that a clog caused by resin drooling was hindering the screw from moving forward. Therefore, we advised to set a pressure reduction distance in the second half of dosing stage, and after that molding became stable.

SATO PARTS CO., LTD. have appreciated our collaborative approach, which has been effective from identifying issues to achieving an early resolution.

SATO PARTS CO.,LTD.'s future strategies

SATO PARTS CO., LTD. is committed to focusing on domestic production and providing high-quality products to their customers, ensuring even greater reliability in their manufacturing processes.

Additionally, they aim to contribute to the educational sector by supplying experimental materials to university laboratories.

Furthermore, they intend to offer intermediate parts for food processing machines and various sensors, as well as maintenance parts to various industrial segments.

Products

Website

https://www.satoparts.co.jp/ENG.html

Factory of SATO PARTS CO.,LTD.

Factory of SATO PARTS CO.,LTD. From left to right: Mr. Ogata, Mr. Yuuki, and Mr. Sato, who we interviewed for this article.

From left to right: Mr. Ogata, Mr. Yuuki, and Mr. Sato, who we interviewed for this article. Screwless terminal block

Screwless terminal block Non-rotating type non-return valve

Non-rotating type non-return valve