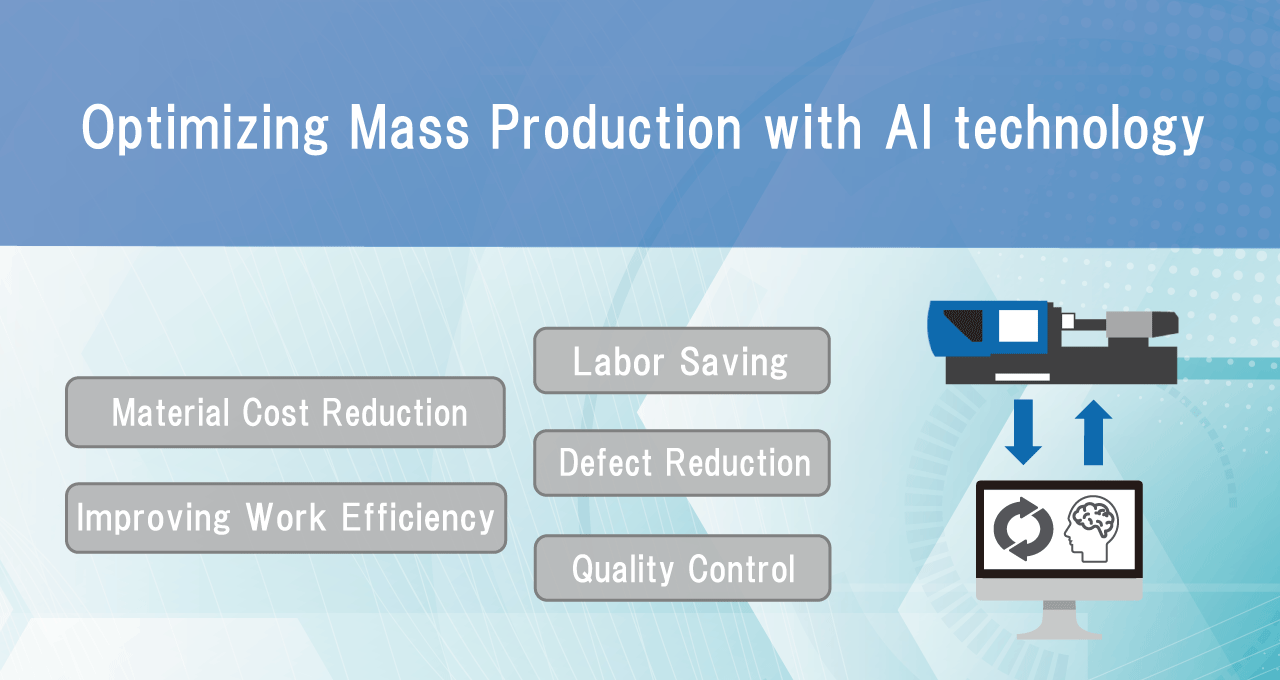

We are pleased to introduce the AI technology "Automatic adjustment of molding process during mass production", which captured significant attention at the recent Nagoya Plastics Industry Exhibition, held from November 20th to 22nd, 2024. This AI-driven technology optimizes molding processes in real-time. When the target values are set, AI automatically adjusts the molding parameters, that helps not only to stabilize quality and improve work efficiency, but also minimize material waste caused by molding defects, as well as labor-costs related to parameter adjustment.

*This technology is introduced for reference only. The release date and sales area will be determined later.

Issues

-The need for recycling has been growing in recent years, but maintaining the same quality with recycled materials remains challenging because of their thermal history.

-Alterations in environmental conditions or changes in resin lots at the production site can cause a drift of the logging data*1, leading to mass disposal of defective products and making it necessary for machine operators to fine-tune the parameters.

-Changes in the molding process have previously relied on the experience and intuition of skilled engineers, but their number is decreasing due to retirement. As a result, the processes are increasingly being set by less experienced operators. It may take them a long time to find parameters that yield good products, or they may end up setting the inappropriate parameter, leading to an increase in defects.

*1 Logging data drift: A phenomenon that refers to gradual changes in performance data logged by an injection molding machine due to changes in resin conditions caused by factors such as fluctuations in air and cooling water temperature, and resin lot changing.

Solutions

AI-driven automatic adjustment of molding processes

Data related to the molding process, such as temperature, pressure, and speed, is collected in real-time and sent to a server, where it is analyzed by AI. Once a variation in molding quality (e.g., product weight) is detected, the molding process will be automatically adjusted to match the target values. The quality data of molded product after adjustment will continue to be monitored, and the adjustment will be made if necessary.

Benefits

Quality stabilization and reduction of defects

When the variations in molding quality occur, AI machine learning is used to automatically determine which settings should be adjusted and how they should be adjusted to achieve the most effective results. Since the parameters are being continuously adjusted to match the target values, logging data drift is prevented. This ensures stable quality and reduces the occurrence of defective products.

Improvement of work efficiency

Automatic process adjustment minimizes the time and effort to move around a large factory or enter and exit clean rooms to adjust the targeted machine's process, thereby improving work efficiency.

Cost reduction

Reducing defective products and improving work efficiency leads to a reduction in overall production costs, including material and labor costs.

Continuous and stable mass production

Automatic adjustment of molding processes before any abnormalities in molding quality are detected ensures continuous and stable mass production. Utilizing automatic adjustment of the molding process during mass production makes it possible to reduce the material and labor costs, while also reducing environmental impact by utilizing recycled materials.

Available models

Please contact our sales representative or use the inquiry form below.

If automatic adjustments can be utilized during mass production, it will be possible to reduce material costs, reduce the environmental impact by using recycled materials, and reduce labor costs.

This technology can be observed at the Technology Center of the Chiba Factory. If you are interested, please contact our sales representative or use our online inquiry form.