PPS (polyphenylene sulfide) is a highly crystalline super engineering plastic with excellent chemical resistance and self-extinguishing properties. However, the high molding temperature of 270~320ºC, poor thermal stability, and high gas generation make stable molding of this resin difficult.

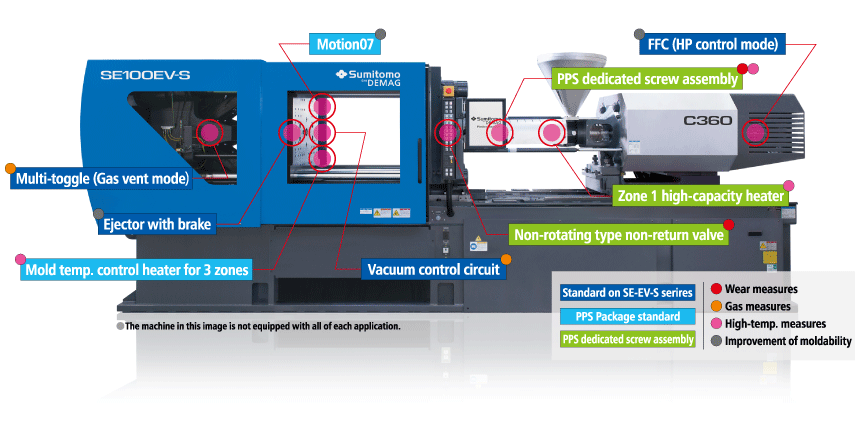

In addition, high GF content increases frictional force and accelerates wear of various components of the screw assembly. In addition to the standard features of the SE-EV series, the integrated operation of the PPS package and dedicated screw assembly enables stable molding of not only PPS but also other super engineering plastics.

Issues

- In addition to corrosive gases, glass fibers can cause wear to the screw assembly and the mold.

- High temperatures and pressures cause instability of plasticization due to wear of screw assembly.

- High gas generation, resulting in cosmetic defects and poor transcription.

- Air vents are easily clogged, resulting in short shots and increased mold corrosion and maintenance.

Solutions

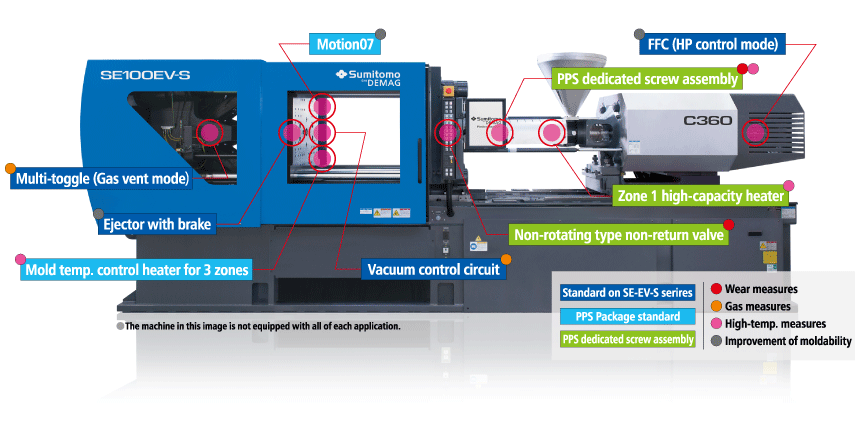

*The machine in this image is not equipped with all of each application.

Wear and high temperature measures

PPS dedicated screw assembly

Special screw assembly to withstand the high temperatures and wear of PPS molding.

Wear measures

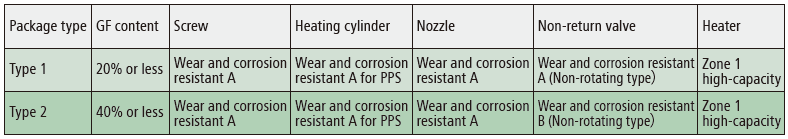

Non-rotating type non-return valve (PPS dedicated screw assembly)

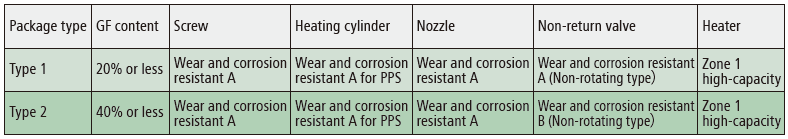

The check ringdoes not rotate with the screw, which reduces wear on the heating cylinder even for resins containing a large amount of GF. Select wear and corrosion resistant A or wear and corrosion resistant B according to the GF content. (See the table above.)

High temperature measures

Zone 1 high-capacity heater (PPS dedicated screw assembly)

Higher capacity heaters of zone 1 ensure stable dosing of PPS, which requires a large amount of heat.

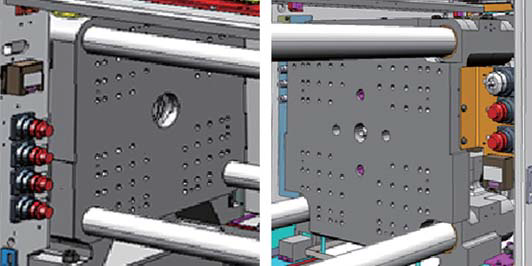

Mold temp. control heater 3 zone (Standard on PPS Package)

A dedicated connection circuit for temperature control is provided for three zones that can accommodate high-capacity heaters for high-temperature molds. The circuits are arranged with two zones on the moving side and one zone on the fixed side, each zone has a capacity of 6.0 kW and comes with two outlets each.

Gas measures

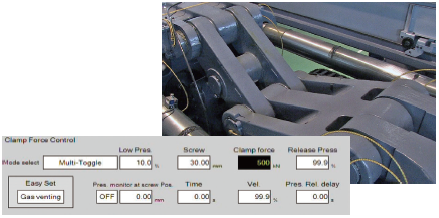

Multi-toggle [Gas vent mode] (Standard on SE-EV series)

Multi-toggle [Gas vent mode], which controls the mold clamping force in multiple stages, effectively releases gases that have flowed into and generated in the cavities. Initial parameters are automatically entered by the easy setup function.

This is an introduction to the main functions only. For items not listed or detailed specifications, please contact us separately.

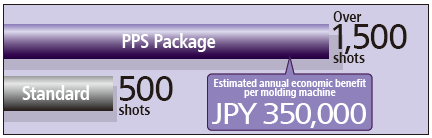

Example benefits

Mold maintenance cycles can be extended by a factor of three or more by greatly reducing the formation of mold deposits caused by gases and the corrosion of mold components.

Improved mold maintenance cycles

- Molding machine:

SE100EV / Product: PPS mechanical component /

- Basis for calculating economic benefit:

Reduction in the number of mold maintenance by 25 per year,

- Unit cost of molding:

1,000 JPY/hr, Maintenance labor costs: 1,000 JPY/hr

Available models

SE-EV-S / SE-EV-A / SE-EV