By connecting molding machine and mold temperature controller through SPICCP*, mold temperature controller can be operated from the molding machine. Not only does this quicken the setup retrieval but it also prevents careless mistakes.

*A communication protocol advocated by an industrial group in the USA.

(The Socienty of the Plastics Industry, inc. Committee on Communication Protocol)

Issues

- Mold damage and wasteful production due to wrong temperature settings

- Mass production continues even if temperature controller fails

Solutions

- Temperature controllers can be controlled (ON/OFF) from the molding machine.

- Temperature settings of the temperature controllers are saved as molding conditions.

- Temperature monitoring settings of temperature controllers can be saved as molding conditions.

Example benefits

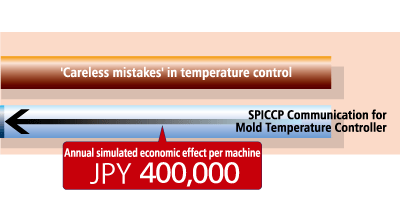

Less production loss by preventing 'careless mistakes'

By eliminating mistakes of temperature control such as wrong temperature settings or continuing mass production without noticing a temperature controller malfunction, the cost of repairing damaged molds or disposing of wasted resin can be reduced.

Estimated annual economic benefit per molding machine 400,000 JPY

Basis for calculating economic benefit

- Extra mold repair cost from mold damage: 2 times/year ( Totaled: 300,000 JPY)

- Extra production loss due to dispose of reject parts: 3 times/year (Totaled: 100,000 JPY)

Technical Specification

Specification of SPI interface

- The specifications of the communication cable are as follows.

●The user procures and provides the cable.

| Cable |

Manufacturers |

| RS-422(4-wired) |

MATSUI, KAWATA |

| RS-485(2-wired) |

HARMO, NAKAMURA, STOLZ |

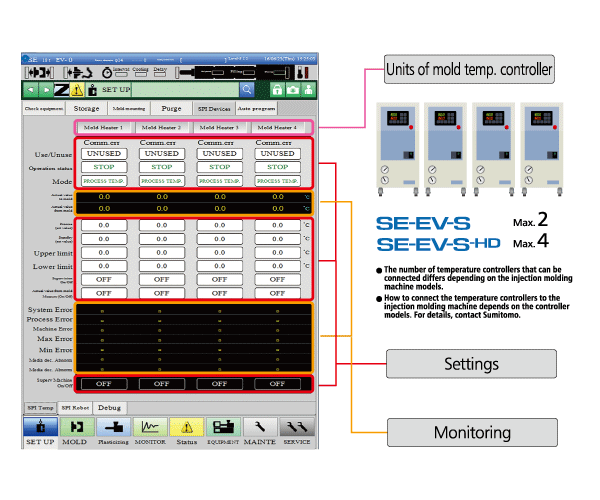

Units of mold temp. controller

SE-EV-S Max.2

SE-EV-S-HD Max.4

- The number of temperature controllers that can be connected differs depending on the injection molding machine models.

- How to connect the temperature controllers to the injection molding machine depends on the controller models. For details, please contact us.

Settings

■Use/Unuse

■Operational status

■Mode (Process/Standby)

■Process mode temperature

■Standby mode temperature

■Upper limit

■Lower limit

■Supervision ON/OFF

■Actual return medium temperature

■measurement ON/OFF*

■Supervision molding machine ON/OFF

- *Available as an option for particular temperature controller models.

Monitoring

■Actual feed medium temperature

■Actual return medium temperature

■System error

■Process error

■Machine error

■Temperature upper limit error

■Temperature lower limit error

■Low medium error

■Communication error

- Applicable maker: MATSUI, HARMO, KAWATA, NAKAMURA and STOLZ

Available models

SE-EV-S / SE-EV-S-HD / SE-EV-A / SE-EV-A-HD / SE-EV