▌ Executives

From left: Kimiaki Yoshimi, Director and Sales Manager / Mikio Koyasu, Director and Manufacturing Manager / Yukio Kurokawa, President / Kazuyoshi Kobayashi, Director and Planning and Management Manager / Katsuyuki Nakano, Director and Engineering Manager

▌ Chronology

| 1949 | ─ Chugai Boeki started importing polyethylene and vinyl chloride |

| 1953 |

Aug. Kyoritsu Plastic Machinery Co., Ltd. was established, and Shigenana Shindo was appointed as Representative Director ─ Chugai Boeki started handling domestically produced blown machines |

| 1955 |

May. At the Plastics Exhibition (hosted by Plastic Age Co.), Chugai Boeki and Kyoritsu Plastic Machinery jointly exhibited a 40mm extruder blown machine Aug. Kyoritsu Plastic Machinery was dissolved Sep. Began preparations to establish a new company, rented a factory of Sanko Sangyo (Kawasaki City), and built an office of about 20m² on adjacent land Oct. Modern Machinery Co., Ltd. was established and held its inaugural meeting (capital 500,000 yen); Toshinori Inoue was appointed President and Representative Director; Masao Kato and Shichiro Morita as Directors; and Tetsuo Ogawa as Auditor Oct. Started production of MK-C-1 model 65mm extruder Nov. Held public demonstration of MK-C-1 model 65mm extruder Nov. Established corporate emblem |

| 1956 |

Apr. Chugai Boeki invested 300,000 yen, increasing capital to 800,000 yen ─ Prototype of MKC 50mm extruder completed ─ Exhibited blown machine with live demonstration at the Spring Plastic Machinery Exhibition (Kobiki Kaikan) ─ Prototype of pipe manufacturing machine completed |

| 1957 |

May. Toshinori Inoue resigned as President and Representative Director; Ryoji Ishigaki appointed as President and Representative Director Oct. Modern Machinery Social Club was established Dec. Chugai Boeki invested 1.2 million yen, increasing capital to 2 million yen ─ Prototype of 65mm extruder blown machine (angled type) completed ─ Prototype of pelletizer and hopper loader completed ─ Demonstrated pipe manufacturing machine at Tokyo International Trade Fair; viewed by the Emperor and Empress of Showa ─ Announced PE pipe manufacturing machine |

| 1958 |

May. Shigenana Shindo and Sanemi Nihimoto appointed as Directors ─ Exhibited crusher at Osaka International Trade Fair ─ Prototype of large polyethylene pipe manufacturing machine completed |

| 1959 |

Jul. Delivered the first export model (40mm extruder blown machine) to Indonesia Sep. Chugai Boeki invested 3 million yen, increasing capital to 5 million yen Sep. Leased 600m² of adjacent land and began construction of new headquarters ─ Developed wire coating machine, T-die, and vented extruder ─ Received bulk order for 65mm extruder, yielding first profit |

| 1960 |

Feb. Ryoji Ishigaki resigned as President and Representative Director; Saburo Atami appointed as President and Representative Director May. Held in-house demonstration exhibition to commemorate completion of new headquarters, displaying four machines including 40mm type III extruder ─ Prototype of new 40mm extruder, slitter, and 800mm die completed |

| 1961 |

─ Installed large lathe and factory monorail ─ Exported one set each of 40mm/50mm blown equipment for Egon ─ Developed 2,200mm wide blown film equipment for agricultural poly film ─ Established employee cafeteria and renovated office |

| 1962 |

Feb. Prototype of 50mm extruder with vent completed Mar. 40mm extruder for vinyl chloride completed Mar. Prototype of 65mm new extruder completed Jun. Formed Modern Cooperation Group with 29 main subcontractors ─ Developed blown film equipment for heavy-duty bags |

| 1963 |

Aug. Developed Egan spiral die and die rotary system Nov. Issued 40% dividend ─ Continued strong performance since 1961; sales exceeded 200 million yen ─ Exhibited Egan spiral die and others at 5th International Trade Fair ─ Strong sales of blown film equipment for heavy-duty bags ─ Exported one set of 65mm blown equipment to the Philippines |

| 1964 |

Feb. Increased capital to 20 million yen

Jul. Saburo Atami resigned as president and became advisor; Michio Isoe became president; Ichiro Ohno became chairman Aug. Planned new employee recruitment and new factory construction due to business expansion; purchased land in Yokohama Oct. Started construction of new factory Dec. Signed factory construction contract with Asahi Kogyo ─ Established new company emblem, philosophy, and motto |

| 1965 |

Jan. President Isoe visited Egan Co. in USA and signed 10-year technical cooperation agreement (Phase 1) Feb. Built new dormitory for single employees May. Completed new Tsunashima head office factory Jun. Held grand opening ceremony and relocated head office Jun. Increased capital to 40 million yen Jun. Held 10th anniversary celebration party ─ Started domestic production of Egan power flight extruder series ─ Started manufacturing extruder laminator, large blown, large cast, and flat yarn under technical cooperation ─ Expanded Egan’s technology adoption to all models |

| 1966 |

─ Promoted rationalization movement ─ Established retirement and bonus regulations ─ Received order for X-500 plasticizer (injection unit), then world’s largest ─ Withdrew from PE pipe equipment production ─ Developed high-speed blown equipment ─ Egan developed three-stage screw ─ Developed water-cooled downward blown equipment for heavy-duty bags ─ Developed MCM equipment ─ Started development of 3,300mm wide large multilayer blown equipment |

| 1967 | ─ Received more orders for large blown equipment due to increased capital investment |

| 1968 |

Oct. Purchased 3,070m² of adjacent land ─ Built second factory ─ Started development of roll-type flat yarn stretching equipment |

| 1969 |

Jan. Signed corporate pension insurance contract with Asahi Seimei ─ Completed 2,400mm wide large casting system ─ Completed roll-type flat yarn stretching machine and started production ─ Completed cast film production system |

| 1970 |

Jun. Received a business diagnosis from the Kanagawa Prefectural Industrial Guidance Office ─ Produced 65mm downward water-cooled blown machine ─ Produced 200mm extruder |

| 1971 |

─ Completed 150mm extruder and 3,500mm wide large shrink film production system ─ Started production of reciprocating screw unit (plasticizer) using technology from U.S. Egan Company ─ Established Special Machinery Division; started design and production of Quick Lock (food packaging sealer) and Labeler (automatic labeling machine) |

| 1972 |

─ Completed 3,300mm wide large multi-layer blown system ─ Achieved sales of 1 billion yen ─ Established workplace roundtable meetings |

| 1973 |

─ Introduced HDPE film molding technology from UK’s Bonklevens Company ─ Trialed bi-weekly two-day-off system |

| 1974 |

Jul. Signed second-phase technical partnership with U.S. Egan Company ─ Succeeded exclusive manufacturing and sales rights for Egan laminators from Minamisenju Plant ─ Changed fiscal year this term to a 4-month business year ─ Adopted bi-weekly two-day-off system ─ Issued overtime restriction notice |

| 1975 |

Jan. Fully implemented ban on overtime work Mar. Completed third plant dedicated to laminator systems May. Michio Isoe resigned as Representative Director and President; Hatsuyoshi Iwai appointed as new Representative Director and President May. Ichiro Ohno resigned as Representative Director and Chairman; became Part-time Director Sep. Delivered single laminator system for flexible packaging Nov. Delivered tandem laminator system ─ Started production of laminator systems ─ Independently developed Delsar-type extruder |

| 1976 |

─ Completed large laminator system for photographic paper ─ Received first order for HDPE blown system from Hong Kong company |

| 1977 |

Oct. Hatsuyoshi Iwai resigned as Representative Director and President; Shigeshiro Shindo appointed as new Representative Director and President ─ Major executive reshuffle: two directors resigned and the auditor was replaced ─ Developed integrated line for HMW HDPE bags (plastic shopping bags) ─ Completed internal-cooling blown system for high-speed heavy-duty bags ─ Doubled capital via 1:1 shareholder allotment, increasing capital to 80 million yen ─ Reformed employee stock ownership plan and significantly increased holdings |

| 1978 |

Mar. Proactively dissolved the Cooperative Association and renamed it "Modern-kai" ─ Started development of high-speed bag-making machine under commission from Ministry of International Trade and Industry ─ Launched high-performance extruder Delsar series ─ Established the 25th Anniversary Celebration Committee and the Factory Renovation Committee |

| 1979 |

Oct. Launched "Modern News" Oct. Demonstrated 50mm HMW HDPE inline machine at Yokohama Industrial Exhibition in Shanghai Dec. Received commendation from Small and Medium Enterprise Agency for high-speed bag-making machine development ─ Achieved 200% revenue growth year-on-year ─ Established Fourth Plant and expanded headquarters building ─ Actively promoted overseas expansion and export strategies ─ Aggressively expanded sales with major trading companies ─ Increased business interactions with China ─ Provided reimplementation of technical assistance contract with U.S. Egan Company to Teijin Seiki ─ Introduced Sharp HAYAC 3700 as office computer ─ Planned introduction of NC machine tools ─ Split the Second Plant into a can manufacturing area and a testing/research lab |

| 1980 |

Apr. Opened Osaka Sales Office May. Held ceremony for 25th anniversary and completion of Second Plant renovation Jun. President Shindo made official visit to China as head of inspection delegation Oct. Started operation of Yamasaki Iron Works' V-15 vertical machining center ─ Developed Uni-loader, high-level heterogeneous material kneading extrusion machine (Patent No. 917122) ─ Launched organizational reform introducing Sales and Production Headquarters system ─ Started MM Campaign as internal rationalization initiative ─ Industry continued depression cartel ─ Started full-scale review of production management system ─ Received consecutive inspection delegations from Beijing Industrial Bureau, Sichuan, Shandong, and Shanghai ─ Established Claims Committee ─ Established Disaster Prevention Committee |

| 1981 |

Apr. Exhibited MB inline system at Tokyo International Trade Fair Sep. Established sales agent PAN MODERN in Singapore Dec. Started operation of MM Campaign ─ Exhibited MB inline system at Singapore Print Pack Exhibition ─ Established PALPAC jointly with Nissho Iwai in Australia ─ Introduced machining center ─ Completed T-die type embossed film production system ─ Completed 65mm extruder / 600mm wide twin-die blown system ─ Conducted skill certification exam of Japan Polyolefin Film Industrial Association ─ Founded baseball team "Delsars" |

| 1982 |

Apr. President Shindo received Commissioner’s Award for contributions to science and technology promotion, and a congratulatory message from the Prime Minister Jul. Kanagawa R&D-oriented Business Council was formed, and President Shindo became the first chairman Sep. Formed technical partnership with UK's EXTRUDAIS, and began domestic production of Muncy 75 Nov. Demonstrated Muncy 75 with computer control (MACS-1) 2-layer blown system at 9th Japan Plastics Fair ─ Introduced large NC lathe ─ Introduced machining center ─ Launched high-efficiency, high-output extruder "High Delsar" ─ Delivered light packaging plant including 65mm extruder and 1,200mm wide laminator system to Dalian, China (exported first low-cost laminator to China) |

| 1983 |

Mar. Delivered first unit of Muncy 75 Apr. Exports to China increased since the latter half of 1981 Aug. Established Management Center ─ Started new production management system ─ Established Safety and Health Committee |

| 1984 |

Apr. Delivered six Muncy 75 units to Taiwan Taffeta Co. May. Demonstrated Delsar 50mm twin-die blown system for L-LDPE at JAPAN PLASTICS 84 Osaka ─ Demonstrated Muncy 55, and ultra-small precision injection molding machine MJEC-10 ─ Exports, especially to China, became more active |

| 1985 |

Apr. Achieved sales of 40 units of ultra-small precision injection molding machine MJEC-10 Apr. Took on first challenge to export a complete plant to India (export via Nikko Resin Development Sudex) Jul. Renovated headquarters office, including entrance and reception room Aug. Introduced CAD Oct. Held 30th anniversary ceremony; received commemorative tree and monument from Chugai Boeki ─ Phase I Product Improvement Committee (JEMCO) project team launched and achieved 150% year-on-year revenue increase |

| 1986 |

Sep. Started the 2nd Phase Product Improvement Committee (JEMCO) project team Nov. Exhibited at Japan Plastics '86, 1,125 companies visited; showcased and demonstrated computer-controlled 3-layer blown equipment, MJEC-10, Defect Inspection System (Laser Eye II), and Curved Surface Screen Printing Machine ─ Launched the Future-Creation P.F. Project |

| 1987 |

Feb. Relocated and expanded the Osaka Sales Office to the 5th floor of the same building Apr. Laminator and casting machines became core products Apr. Sales of the MACS microcomputer control system increased Apr. Orders for small 40mm and 50mm extruders dropped sharply Apr. Exhibited multilayer casting machine at Japan’s first converting machinery fair (CMM); later installed permanently in our research lab Jun. Conducted training camp on DC motors, inverters, and computers at Sumitomo Drive System Jul. Launched the first MAPS35 activity aiming at 35% cost reduction (until Nov. 1987) ─ Conducted internal survey for Future-Creation P.F. Project ─ Developed high-performance air ring AL for L-LDPE and LDPE, commercialized as a series ─ Completed new die for HMW/HDPE and high-speed forming air ring HT type ─ Completed system meeting the first-stage conditions of automatic operation by MACS ─ Delivered laminator for multilayer co-extrusion testing to a resin manufacturer |

| 1988 |

Feb. Mr. Pierfelice, new president of Egan Company (USA), visited Feb. Submitted external survey for Future-Creation P.F. Project Feb. 2nd MAPS activity (until Jul. 1988) Apr. Established Planning and Development Department Jun. Formed Future-Creation Project Team Jul. President Shigenana Shindo passed away; Yoshihiro Okabe became President Nov. Exhibited fully automatic unmanned blown machine and ultra-compact precision injection molding machine MJEC-10 at 12th Japan Plastics & Rubber Fair; about 2,000 visitors came to our booth ─ Delivered first export tandem laminator with computer control system to FLEXO Corp. (Philippines) ─ Enhanced technical support staff, increased female staff |

| 1989 |

Apr. First year of the 1st Mid-Term Plan Jul. Held in-house exhibition of fully automatic unmanned blown equipment MFA50/600 model Aug. Delivered large laminator equipment to four major converters ─ Started production of fully automatic unmanned blown film production equipment ─ Introduced Fanuc OM-B automatic programming system for machining NC production PS-100/CNT75 ─ Established structure for Production and Management Departments ─ Installed NC screw lathe ─ Purchased Auto Die CMR2000 ─ Prepared introduction of new office computer |

| 1990 |

Jan. Started operation of new office computer system METS Jan. Renewed agreement with Egan Company (USA) in a new format Apr. Started special holiday system Apr. Implemented new travel expense regulations Apr. Exhibited many machines centered on CMR2000 and Auto Die at 2nd International Converting Equipment Fair Apr. Achieved 200,000 hours of zero-accident record Jul. Completed technical cooperation project for agricultural mulch film production for China; President Okabe visited Beijing Oct. Held 35th anniversary ceremony; number of employees grew 8-fold and sales 163-fold since founding Oct. Announced investments: rebuilding of 2nd plant, installation of new T-die processor, setup of design search system Oct. Introduced large machine tools AJV35 and DP130WD complex planer Nov. Demolished 2nd plant and started construction of new 2nd plant Nov. Exhibited OMP (Italy) Perest 85 recycling system, Mach 50 super high-speed blown machine, and Moss curved surface printer at 13th Japan Plastics & Rubber Fair JP90 ─ Signed exclusive distributorship agreement with OMP (Italy) for Japan and Southeast Asia ─ Developed device to directly add polybutene (adhesive) through screw during film molding ─ Relocated can-making factory |

| 1991 |

Mar. Introduced Yellow Card (complaint countermeasure card) Jun. New Second Factory completed ─ Delivered Japan’s fastest laminator test equipment to resin manufacturer S Corp. ─ Losses increased due to rising number of complaints ─ Expanded CAD and METS terminals ─ Established Technical Center (MTEC) at a leased external factory ─ Unified company logo, changed company name typeface and image color ─ Baseball team "Delsars" celebrates its 10th anniversary |

| 1992 |

Jan. Introduced surface grinding machine PSG-305DX Apr. Exhibited at trade fairs in Mexico, Vietnam, and Thailand Apr. Exhibited laminate/cast/sheet combo machine and Pellerst at plastic fair CMM JAPAN 3 Oct. Accepted foreign trainees through Yokohama Overseas Exchange Association Nov. First overseas company trip (Hawaii) conducted ─ Delivered fully automatic unmanned blown machine to Nagoya K Corp. ─ Strong overseas orders ─ Implemented two no-overtime days per week; transitioned to full two-day weekends |

| 1993 |

Apr. Improvement campaign "Operation S" launched Sep. Farewell party held for retirees ─ Conducted awareness activities for the Product Liability (PL) Law |

| 1994 |

Jan. Demonstrated fully automatic blown equipment and recycling machines at the 1st International Plastic Fair (IPF) Jan. Announced annual goals: "Reduce complaints" and "Globalization" Nov. Signed exclusive sales agreement with Battenfeld Extrusions Technik (BEX) Nov. Reconstruction of First Factory completed; MTEC established |

| 1995 |

Feb. Delivered Japan's first large-scale 5-layer blown machine to major film processing company Mar. Posted a deficit (first since March 1976) Aug. Suspended publication of "Modern News" Sep. Organizational reform implemented (merged departments into functional units; changed management roles to qualification-based positions) Oct. Marked 40th anniversary of founding Dec. Concluded renewed contract and technology partnership with Egan Co., USA ─ Released automatic thickness-adjusting T-die (Sumitomo Heavy Industries) ─ Independently developed medical multilayer blown system, optical sheet system, flex roll, and auto air ring |

| 1996 |

May. Germany and Italy held exhibitions for packaging and converting machinery Oct. "Metallocene Fair '96" (a private show) was held, attracting 477 visitors from 225 companies Oct. Plastic trade fair (IPF) held Oct. Announced launch of surveillance camera business (new division) Dec. A problem occurred with a 3-layer agricultural PO blown system delivered to a major film processing company, but was not resolved within the year |

| 1997 |

Jan. Began testing and PR of high-clarity PP sheet manufacturing system Flex Roll machine for a resin manufacturer Feb. Announced capital increase and expansion of executives; became 100% owned by Chugai Boeki ─ Developed Flex Roll |

| 1998 | ─ Changed company name to "Chugai Tech Co., Ltd." |

| 1999 |

Jan. Changed company name to "CBC Tech Co., Ltd." Apr. Yoshihiro Okabe resigned as President; Katsuhiro Ichikawa appointed as President ─ Announced high-speed cast film/sheet/laminator multifunctional system "Multi-in-One", installed in MTEC for in-house testing ─ Sold third and fourth factories |

| 2000 |

Nov. A new company was established with 100% investment by Sumitomo Heavy Industries, Ltd., and renamed "SHI Modern Machinery Co., Ltd." with Hiroshi Makishima appointed as President Dec. Joined domestic and international PL insurance Dec. Increased overseas sales staff Dec. Cost Reduction Committee began activities ─ Withdrew from businesses in surveillance cameras, synthetic resin products, and vacuum deposition |

| 2001 |

Feb. blown Strategy Committee begins activities Mar. Started VE education Mar. Promoted joint marketing with Sumitomo Heavy Industries Mar. Eliminated bad debts and unnecessary assets Apr. Changed salary system to performance-based Jul. Strengthened material procurement function Sep. Completed withdrawal from ED business (returned to CBC) ─ Developed automatic thickness adjustment air ring ─ Designated Company S in addition to Korean Company N as outsourcing partner |

| 2002 |

Jan. Held New Year’s gathering with partner companies, approx. 130 participants from 86 firms Jul. blown Strategy Committee concluded with 17th meeting Sep. China Strategy Committee launched Nov. Exhibited at IPF2002 (Makuhari): auto thickness-adjustable air ring, Type-13 T-die, ZA adapter, Flex Roll ─ Joined trade insurance organization ─ Started free inspection service ─ Announced DMA-type automatic thickness adjustment air ring |

| 2003 |

May. Opened Shanghai representative office May. Exhibited at INTERPHEX Tokyo (Pharmaceutical Expo) Aug. Integrated with Plastics Machinery Division of Sumitomo Heavy Industries, renamed to “Sumitomo Heavy Industries Modern Ltd.” Nov. Started major project review meetings |

| 2004 |

Jun. First exhibition at Chinaplas 2004 in Shanghai Jun. Leased new Fuji Factory (until Dec. 2005) Jul. In-house assembly workload reached 3,000–4,000 hours/month, causing factory capacity shortage ─ blown 50th Anniversary Model Development Committee established |

| 2005 |

Apr. First exhibition at Flat Panel Display (FPD) show Apr. Achieved record profits for 4 consecutive terms; operating profit margin reached 6.6% May. President Hiroshi Makishima resigned; Yoshikazu Takeichi appointed President Oct. Established Quality Assurance Dept.; launched 3 project teams Oct. Published 50th anniversary commemorative collection Dec. Withdrew from Fuji Factory Dec. Leased Building B of Sumitomo Heavy Industries Chiba Factory and began assembly operations |

| 2006 |

Apr. Established the Development Group within the Technical Department Jun. Held a Special Delivery Adjustment Meeting Jul. Inspection conducted by President Hinoue of Sumitomo Heavy Industries Sep. Announced Medium-Term Plan (HOP70) Oct. Launched the Process Management Project Team Oct. New Production Management System began operation Oct. Held briefing and public discussion on the Medium-Term Plan ─ Developed the 50th Anniversary blown model machine ─ Introduced an Educational Program ─ Announced entry into and establishment of business in the optical-related market ─ Increased demand for multilayer films for packaging materials |

| 2007 |

Mar. Completed standardized light packaging laminator Apr. Established new organization (Quotation Group / Process Group) Jul. Introduced new personnel system Oct. Segment Sales Activity System launched |

| 2008 |

Jan. Started operation of new Futtsu Plant (Chiba) to supplement production capacity Apr. Conducted Executive Training Seminar ─ Established Cost Group |

| 2009 |

Apr. Exhibited at FPD Show (first unveiling of automatic thickness control T-die) Apr. Implemented training due to underoperation May. Problem-Solving Task Force launched to develop new customers Dec. Acquired ISO14001 certification |

| 2010 |

Jan. Delivered a three-layer downward blown system with water cooling for infusion bags to a major Chinese medical device manufacturer Jan. Delivered a three-layer optical cast system for Korea Apr. Exhibited at High-Performance Film Technology Exhibition |

| 2011 |

Jan. Acquired ISO9001 certification Mar. Yorinari Takeichi stepped down as President and CEO, and Shingo Tsuda was appointed Apr. Exhibited at High Performance Film Technology Exhibition Apr. Export of laminator equipment doubled compared to the previous three years Jul. Launched Fire and Explosion Risk Control Matrix Aug. Dispatched employees to SPM Shanghai and SHI Indonesia to promote globalization Aug. Conducted environmental audit Oct. First exhibit at PLOPACK Indonesia (joint exhibition with SHI Group companies including Izumi Food Machinery) Dec. Delivered a 3-layer co-extrusion tandem laminator to Ukraine ─ Started training for new engineering employees on assembly work at the Futtsu Plant |

| 2012 |

Feb. Held company-wide briefing session on compliance Mar. Achieved record annual sales of 6 billion yen in FY2011 and distributed commemorative gifts to employees Apr. Established Human Resources and General Affairs Group and Production Engineering Team Apr. Exhibited jointly with SPM Shanghai (SHI Plastics Machinery Division’s local subsidiary) at Chinaplas Shanghai Jul. Reorganized Technical Services and established CS Team and Inspection Team Dec. Dissolved Workplace Roundtable and established labor union, joined Sumitomo Heavy Industries Labor Federation ─ Designated as a “Special Safety Measures Site” within SHI Group ─ Launched new concept MLA-SP single laminator for Asian markets ─ New university graduates participated in SHI Group’s 3-year introductory training program |

| 2013 |

Apr. Reorganized to integrate Process Group and Logistics Group Apr. Developed new agencies in India and the Philippines; exhibited in Thailand, Indonesia, Shanghai, Philippines, and Vietnam May. Revised ISO9001 Quality Manual Jun. Delivered two tandem laminator lines for release liner to China Oct. Company trip held in Taiwan ─ Started T-die machining at SHI Plastics Machinery Division, Chiba Works ─ Held young engineer training by SHI retiree Seiya Sakai for junior staff in Engineering Department |

| 2014 |

Mar. Shingo Tsuda stepped down as President and CEO, Yukio Kurokawa appointed Apr. Established Operations Group within Sales Department Apr. Formulated “Mid-Term Plan 2016” Apr. Appointed safety and health supervisor and strengthened functions May. Expanded Futtsu Plant Jun. SHI Advisor Hinou gave management lectures to executive employees Jul. Delivered triple laminator for paper to China Jul. Established sales and service base in Thailand Sep. Exhibited at PLOPACK Asia Myanmar |

| 2015 |

Jan. Launched sales of new Smart Flipper Sep. Held 60th anniversary private show Oct. Held 60th anniversary commemorative ceremony ─ Launched sales of energy-saving extruder and Smart Chamber |

| 2016 |

Mar. Updated test equipment for laminator, cast, and sheet use (S-2) Jul. Received first order for blow molding machine for fuel tanks ─ Started full operation of inner surface polishing robot for T-dies |

| 2017 |

Jan. Began consideration of brand design Apr. Formulated “Mid-Term Plan 2019” Oct. Exhibited at IPF2017 and introduced Dolphin brand development |

| 2018 |

Mar. Introduced new machining center to increase T-die production May. Delivered laminator equipment to UAE Jun. Expanded Building C of Futtsu Plant and consolidated assembly process there |

| 2019 |

May. Installed Dolphin Blown blown test equipment at Yokohama Head Office Plant Jul. Held training session for Futtsu City educators at Futtsu Plant Aug. Obtained CE compliance certificate for “SMART FRIPPER SYSTEM” Oct. First exhibited at K-2019 Show in Germany Dec. Received first order for full line of LCP-dedicated blown equipment |

| 2020 |

Apr. Formulated “Mid-Term Plan 2022” Oct. Delivered global standard safety-spec laminator Nov. Opened satellite office at Yokohama Second Plant in response to COVID-19 pandemic Nov. Exhibited at IPF2020 Virtual Show during COVID-19 pandemic |

| 2021 |

Apr. Revised to “Mid-Term Plan 2023” due to COVID-19 pandemic ─ Due to the pandemic, hotel quarantine of two weeks required upon entry to China ─ Remote work and web meetings became the norm due to COVID-19 |

| 2022 |

Oct. Exhibited new recycling equipment at TOKYO PACK and launched sales Dec. Solar power generation started at Futtsu Plant No.1 ─ Semiconductor shortage made procurement of electrical components difficult |

| 2023 |

Jan. Formulated “Mid-Term Plan 2026” Sep. Completed Futtsu Plant No.2; centralized processing at Futtsu Sep. Held process review at Futtsu Plant No.2 Oct. Delivered Dolphin Lami Units 1 and 2 ─ Started full-scale in-house production of round dies ─ Resumed social gathering events |

| 2024 |

Jan. Reviewed “Mid-Term Plan 2026” due to global political and economic uncertainty Feb. Held a factory tour at Futtsu Plant for local elementary school students ─ Launched sales of Hybrid Air Ring ─ Held private show for automatic startup of blown equipment |

| 2025 |

─ Launched sales of new MACS ─ Launched sales of new SMART FRIPPER SYSTEM Oct. 70th anniversary of founding |

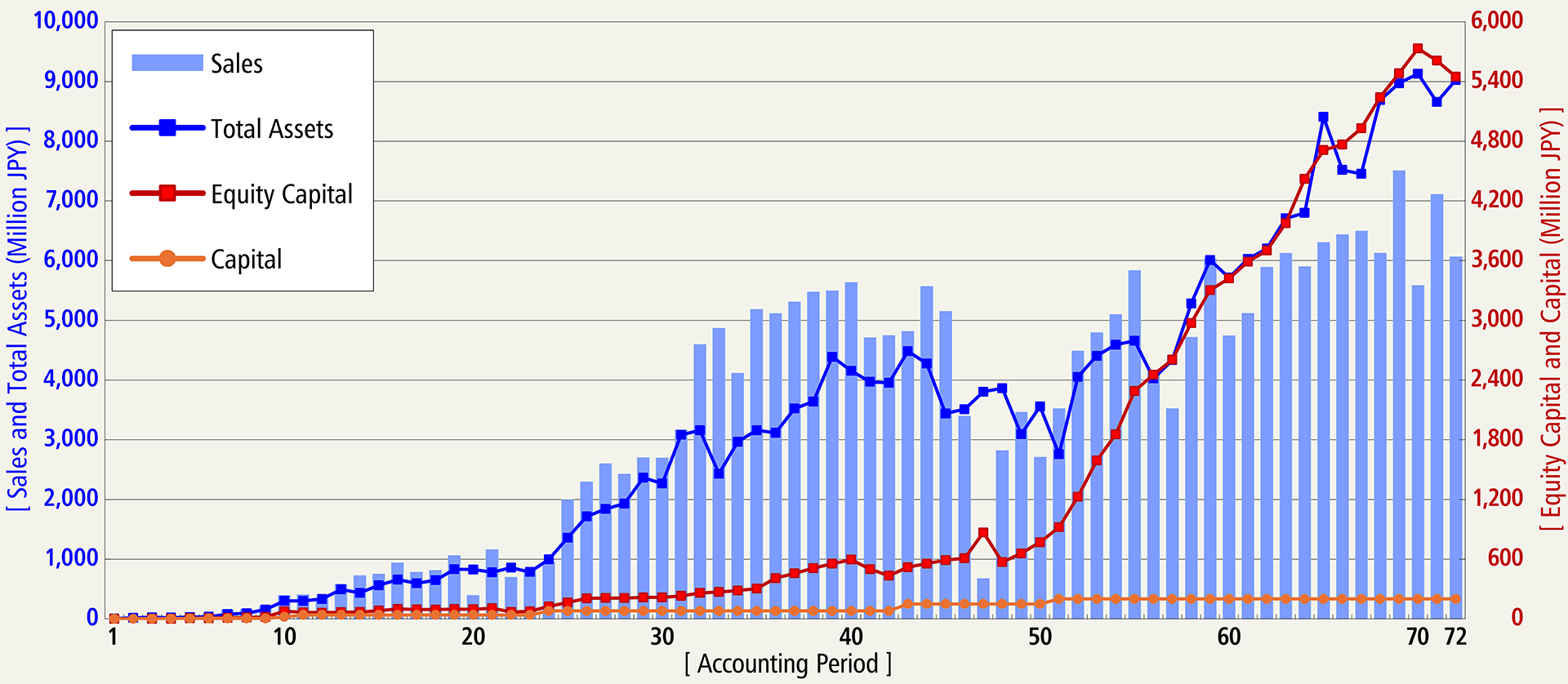

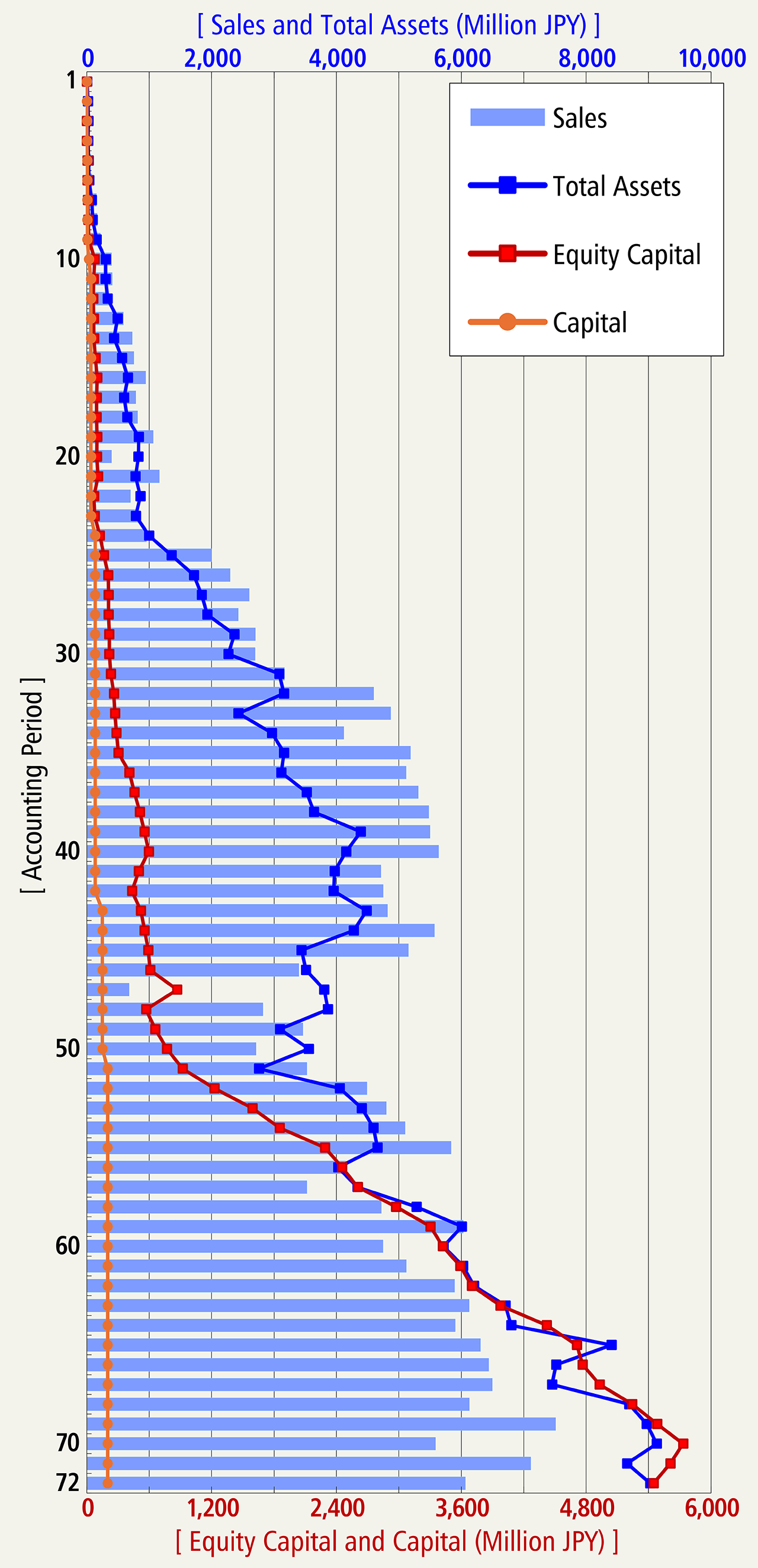

▌ Performance Trends

Sumitomo Heavy Industries Modern, Ltd. 8-32-16 Shinyoshida-higashi, Kohoku-ku, Yokohama City 223-8511, Japan

Tel: +81-45-547-7777 Fax: +81-45-547-7717

Copyright 2025 Sumitomo Heavy Industries Modern, Ltd. All Rights Reserved.