Injection molding defects can occur depend on the polymer and mold product.

By the diversification of plastic parts, there are various factors and countermeasures.

In this seminar, we will explain about low clamping force

technology,

which is one of the features of the Sumitomo molding machine.

We propose effective solutions such as injection control, screw design, sensing and clamping mechanism.

Contents

- Introduction of injection molding

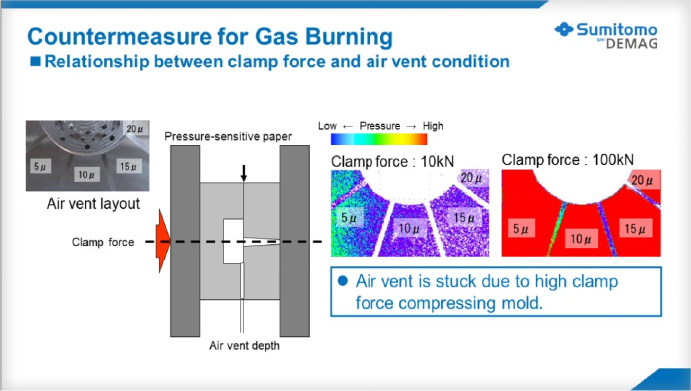

- Advantages and disadvantages of injection molding with low clamping force.

- Example cases of gas burning, burrs and yellowing.

- Introduction of our technology,

including the explanation about factors and countermeasure of molding defects.

This seminar is recommended for those who are:

- Lack of experience in reducing clamp force

- Willing to solve molding defects

- Facing a problem of gas burning, burrs and yellowing

Outline of the event

| How to participate | You will be notified of the new arrival information on the front page and in the mail magazine when the participation method is held. |

|---|---|

| Participation fee | Free of charge |

| Target | Injection molding machine users. |

| Format | Online Seminar via ZOOM |

| Instructor | Mr. Lee (Sales Engineering Department) |

| Contact us | Sumitomo Heavy Industries, Ltd. Sales Department, Plastics Machinery Division TEL:03-6737-2576 MAIL: shi.pm.sales.info@shi-g.com |

| Note | We may not accept applications from other companies in the same industry or our competitors. |