Filter by Application

-

Mechanical parts

-

Appearance parts

-

Medical equipment

-

Daily necessities

-

Micro parts

-

Optical parts

-

Food containers

-

Horizontal

Sustainable Molding

Designed and built with sustainability in mind, our standard model reduces both

defects and power consumption through low injection pressure, low mold clamping

force and simple operation. Enhanced basic performance and a variety of

applications enable an environmentally friendly production.

300kN - 1800kN

-

Horizontal

Super High Response

This model improves high-speed injection performance and high-response

acceleration/deceleration performance. The fast, quick-response filling it

delivers better reproduces molding process with respect to settings and reduces

defects seen in thin-wall molding.

500kN - 4500kN

-

Horizontal

All-electric small-sized injection molding machine dedicated to small-size

precision

This compact all-electric molding machine delivers fast-cycle performance in a

small footprint. It brings both precision and stability to fast-cycle molding.

170kN

-

Horizontal

Advanced all-electric medium-sized injection molding machine

This medium-sized injection molding machine is eqipped with a variety of functions

enabling molding with low mold clamping force. It has the featers that allow to

setup the bigger molds compare with other similar machines. Low initial costs and

low space requirement are the benefits of using this machine.

2200kN - 5000kN

-

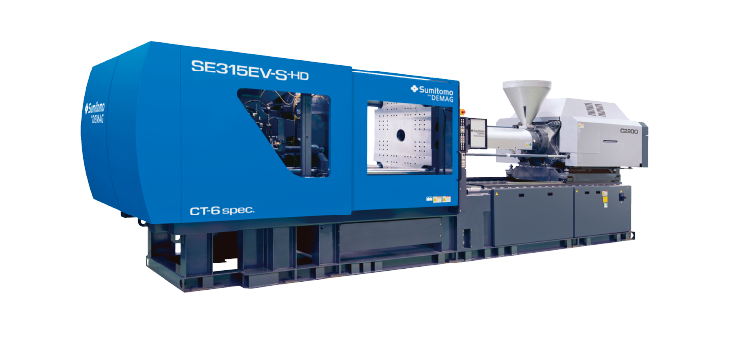

Horizontal

High cost performance fast cycle machine

This special specification model of the SE-EV-S-HD performs fast-cycle molding of

products of thin to medium thickness walls. It improves filling and plasticization

capacity without sacrificing the small footprint and expandability of the base

model.

2200kN - 5000kN

-

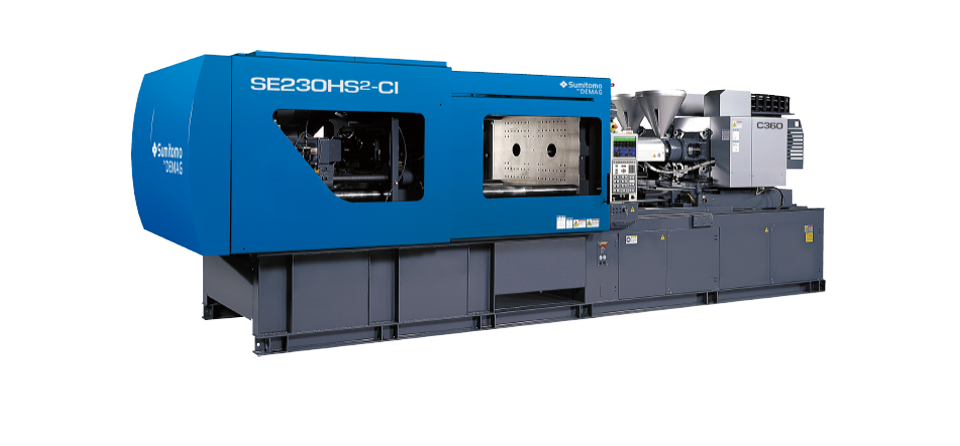

Horizontal

High-speed type all-electric molding machine

This fast-cycle machine for thin-walled products increases the speed of the

injection unit and clamping unit. It incorporates a low-inertia, high-response

direct drive that enables precision molding.

2150kN - 3430kN

-

Double-shot

Comfortable composite molding compact two-material machine

This all-electric molding machine is not only capable of making products of higher

functionality, but it also shortens processing by enabling composite molding with

two resins. It is equipped with an injection unit with the direct drive system and

high-speed rotary table that promote high quality, efficient production.

730kN - 1270kN

-

Double-shot

Composite molding realized in middle size

This all-electric molding machine is not only capable of making products of higher

functionality, but it also shortens processing by enabling composite molding with

two resins. It is equipped with an injection unit with the direct drive system and

high-speed rotary table that promote high quality, efficient production.

2250kN - 2740kN

-

Double-shot

World's largest class of all-electric double-shot molding machines

This model is one of the world's largest all electric double-shot molding

machines. The wide platen with expanded tie-bar clearance and the original

temperature control piping system make it possible to mount large molds.

4000kN

-

Horizontal

Lead to next-generation lens molding

This model comes with features for ensuring the eccentricity accuracy, appearance

and thin walls required in optical lens molding. Its high-performance mold

clamping unit, screw assembly and injection unit are designed and built for

molding ever-changing optical lenses.

300kN - 500kN

-

Horizontal

Further precision of small and high-cycle molding

This connector-specific model comes with a more durable mold clamping unit and

injection unit needed to mold small products at faster cycling pace than usual.

Thanks to the machine’s high-precision performance, users shorten the amount of

time spent performing maintenance and decrease the amount of resin they waste,

which reduces their running costs

300kN

-

Horizontal

It allows for a cleaner environment by motorization

This is an injection blow molding machine that achieves stable, high-quality

molding through the synergistic effect of injection and mold technologies.

1300kN

-

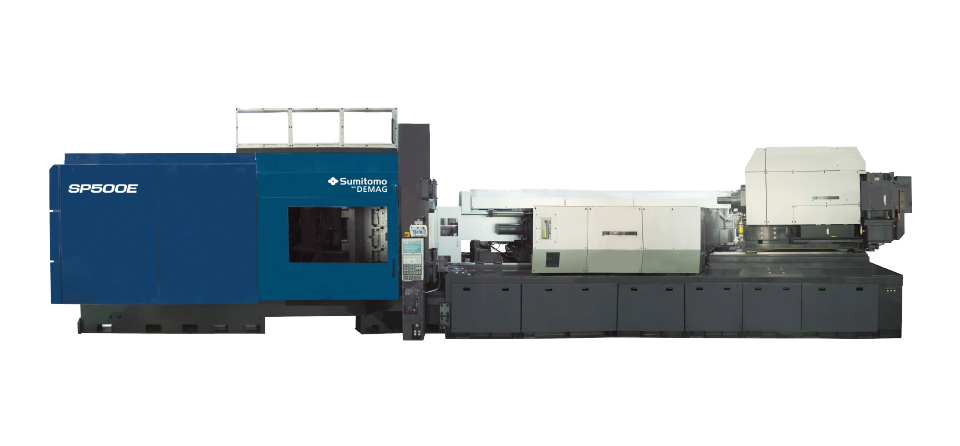

Horizontal

Achieves further energy savings

The molding machine dedicated for PET preform that achieves fast-cycle, stable

production while saving energy. Owing to its electrical technologies, it reduces

power consumption by 30% or more over hydraulic machines of the same class

5000kN

-

Horizontal

Dedicated high-performance container molding

This high-performance version of the SE-HSZ2 offers the high rigidity and low

vibrations needed to mold ultra-thin-walled containers. It produces with

multi-cavity molds at a fast pace of 3 sec/cycle.

2740kN - 3430kN

No applicable products were found.